Engine Component Improvement Project

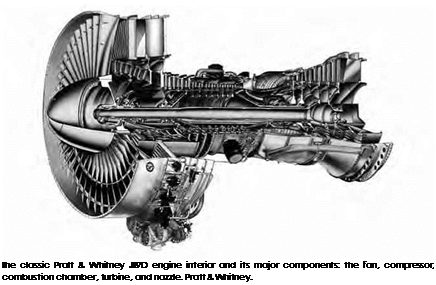

The Engine Component Improvement project was tasked with enhancing performance and lowering fuel consumption of several existing commercial aircraft jet engines, in particular Pratt & Whitney’s JT8D and JT9D engines and GE’s CF6. The specific goals included:

• Improving the current versions of the engines without requiring a brand-new design or engine replacement.

• Reducing the amount of fuel a typical jet engine would use on any given flight by 5 to 6 percent.

• Significantly slowing the pace at which the engine’s components would naturally degrade and cause a loss of performance over time.

To do this, researchers tried and tested several ideas, including reducing the clearance between rotating parts, lowering the amount of cooling air that is passed through the engine, and making refinements to the aerodynamic design of certain engine parts to raise their efficiency. All together, engineers identified 16 concepts to incorporate into the engines.[1309]

Ultimately, as a result of the Engine Component Improvement efforts, engine parts were incorporated that could resist erosion and warping, better seals were introduced, an improved compressor design was used, and ceramic coatings were added to the gas turbine blades to increase their performance. Tests of the improvements were so promising that many were put into production before the program ended, benefiting the

|

|

workhorse airliners at the time, namely the McDonnell-Douglas DC-9 and DC-10, as well as the Boeing 727, 737, and 747.[1310]