Noise Pollution Forces Engine Improvements

Fast-forward a few years, to a time when Americans embraced the promise that technology would solve the world’s problems, raced the Soviet Union to the Moon, and looked forward to owning personal family hovercraft, just like they saw on the TV show The Jetsons. And during that same decade of the 1960s, the American public became more and more comfortable flying aboard commercial airliners equipped with the modern marvel of turbojet engines. Boeing 707s and McDonnell-Douglas DC-8s, each with four engines bolted to their wings, were not only a common sight in the skies over major cities, but their presence could also easily be heard by anyone living next to or near where the planes took off and landed. Boeing 727s and 737s soon followed. At the same

|

|

time that commercial aviation exploded, people moved away from the metropolis to embrace the suburban lifestyle. Neighborhoods began to spring up immediately adjacent to airports that originally were built far from the city, and the new neighbors didn’t like the sound of what they hearing.[1295]

By 1966, the problem of aircraft noise pollution had grown to the point of attracting the attention of President Lyndon Johnson, who then directed the U. S. Office of Science and Technology to set a new national policy that said:

![]() The FAA and/or NASA, using qualified contractors as necessary, (should) establish and fund. . . an urgent program for conducting the physical, psycho-acoustical, sociological, and other research results needed to provide the basis for quantitative noise evaluation techniques which can be used. . . for hardware and operational specifications.[1296]

The FAA and/or NASA, using qualified contractors as necessary, (should) establish and fund. . . an urgent program for conducting the physical, psycho-acoustical, sociological, and other research results needed to provide the basis for quantitative noise evaluation techniques which can be used. . . for hardware and operational specifications.[1296]

As a result, NASA began dedicating resources to aggressively address aircraft noise and sought to contract much of the work to industry, with the goals of advancing technology and conducting research to provide lawmakers with the information they needed to make informed regulatory decisions.[1297]

During 1968, the Federal Aviation Administration (FAA) was given authority to implement aircraft noise standards for the airline industry. Within a year, the new standards were adopted and called for all new designs of subsonic jet aircraft to meet certain criteria. Aircraft that met these standards were called Stage 2 aircraft, while the older planes that did not meet the standards were called Stage 1 aircraft. Stage 1 aircraft over 75,000 pounds were banned from flying to or from U. S. airports as of January 1, 1985. The cycle repeated itself with the establishment of Stage 3 aircraft in 1977, with Stage 2 aircraft needing to be phased out by the end of 1999. (Some of the Stage 2 aircraft engines were modified to meet Stage 3 aircraft standards.) In 2005, the FAA adopted an even stricter noise standard, which is Stage 4. All new aircraft designs submitted to the FAA on or after July 5, 2005, must meet Stage 4 requirements. As of this writing, there is no timetable for the mandatory phaseout of Stage 3 aircraft.[1298]

With every new set of regulations, the airline industry required upgrades to its jet engines, if not wholesale new designs. So having already helped establish reliable working versions of each of the major types of jet engines—i. e., turboprop, turbojet, and turbofan—NASA and its industry partners began what has turned out to be a continuing 50-year-long challenge to constantly improve the design of jet engines to prolong their life, make them more fuel efficient, and reduce their environmental impact in terms of air and noise pollution. With this new direction, NASA set in motion three initial programs.9

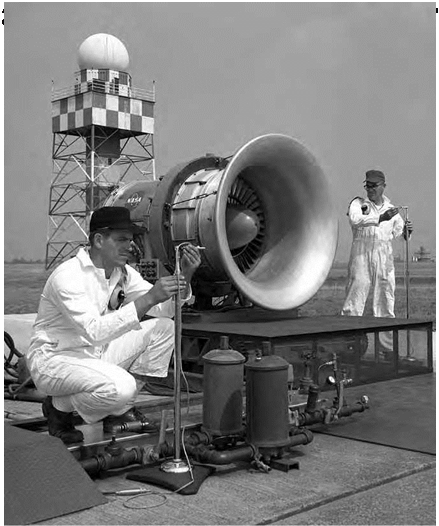

![]() NASA’s first major new program was the Acoustically Treated Nacelle program, managed by the Langley Research Center. Engines flying on Douglas DC-8 and Boeing 707 aircraft were outfitted with experimental mufflers, which reduced noise during approach and landing but had negligible effect on noise pollution during takeoff, according to program results reported during a 1969 conference at Langley.10

NASA’s first major new program was the Acoustically Treated Nacelle program, managed by the Langley Research Center. Engines flying on Douglas DC-8 and Boeing 707 aircraft were outfitted with experimental mufflers, which reduced noise during approach and landing but had negligible effect on noise pollution during takeoff, according to program results reported during a 1969 conference at Langley.10

The second was the Quiet Engine program, which was managed by the Lewis Research Center in Cleveland (Lewis became the Glenn Research Center on March 1, 1999). Attention here focused on the interior design of turbojet and turbofan engines to make them quieter by as much as 20 decibels. General Electric (GE) was the key industry partner in this program, which showed that noise reduction was possible by several methods, including changing the rotational speed of the fan, increasing the fan bypass ratio, and adjusting the spacing of rotating and stationary parts.11

The third was the Steep Approach program, which was jointly managed by Langley and the Ames Research Center/Dryden Flight Research Facility, both in California. This program did not result in new engine technology but instead focused on minimizing noise on the ground by developing techniques for pilots to use in flying steeper and faster approaches to airports.12 [1299] [1300]