Blade Fabrication

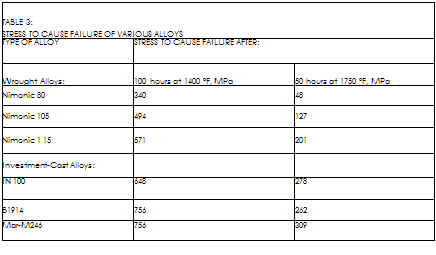

The fabrication of turbine blades represents a related topic. No blade has indefinite life, for blades are highly stressed and must resist creep while operating under continuous high temperatures. Table 3 is taken from the journal Metallurgia and summarizes the stress to cause rupture in both wrought – and investment-case nickel – base superalloy.[1092]

|

|

An important development involved the introduction of directionally solidified (d. s.) castings. Their advent, into military engines in 1969 and commercial engines in 1974, brought significant increases in allowable metal temperatures and rotor speeds. D. s. blades and vanes were fabricated by pouring molten superalloy into a ceramic mold seated on a water-cooled copper chill plate. Grains nucleate on the chill surface and grow in a columnar manner parallel to a temperature gradient. These columnar grains fill the mold and solidify to form the casting.[1093]

A further development involved single-crystal blades. More was required here than development of a solidification technique; it was necessary to consider as well the entire superalloy. It was to achieve a high melting temperature by containing no grain boundary-strengthening elements such as boron, carbon, hafnium, and zirconium. It would achieve high creep strength with a high gamma-prime temperature. A high temperature for solution heat treatment would also provide improved properties.

The specialized Alloy 454 had the best properties. It showed a complete absence of all grain boundary-strengthening elements and made significant use of tantalum, which suppressed a serious casting defect known as "freckling.” Chromium and aluminum were included to protect against oxidation and hot corrosion. It had a composition of 12Ta+4W+10Cr+5Al+1.5Ti+5Co, balance Ni.

Single-crystal blades were fabricated using a variant of the cited d. s. arrangement. Instead of having the ceramic mold rest directly on the chill

|

|

plate, it was separated from this plate by a helical single-crystal selector. A number of grains nucleated at the bottom of the selector, but most of them had their growth cut off by its walls, and only one grain emerged at the top. This grain was then allowed to grow and fill the entire mold cavity.

Creep-rupture tests showed that Alloy 454 had a temperature advantage of 75 to 125 °F over d. s. MAR-M200 + Hf, the strongest production-blade alloy. A 75 °F improvement in metal temperature capability corresponds to threefold improvement in life. Single-crystal Alloy 454 thus was chosen as the material for the first-stage turbine blades of the JT9D-7R4 series of engines that were to power the Boeing 767 and the Airbus A310 aircraft, with engine certification and initial production shipments occurring in July 1980.[1094]