Cooling

Hypersonics has much to say about heating, so it is no surprise that it also has something to say about cooling. Active cooling merits only slight attention, as in the earlier discussion of Dyna-Soar. Indeed, two books on Shuttle technology run for hundreds of pages and give complete treatments of tiles for thermal protection—but give not a word about active cooling.[1077]

What the topic of cooling mostly comprises is the use of passive cooling, which allowed the Shuttle to be built of aluminum.

During the early 1970s, when there was plenty of talk of using a liquid-fueled booster from Marshall Space Flight Center, many designers considered building that booster largely of aluminum. This raised the question of how bare aluminum, without protection, could serve in a Shuttle booster. It was common understanding that aluminum airframes lost strength because of aerodynamic heating at speeds beyond Mach 2, with titanium being necessary at higher speeds. But this held true for aircraft in cruise, which faced their temperatures continually. Boeing’s reusable booster was to reenter at Mach 7, matching the top speed of the X-15. Still, its thermal environment resembled a fire that does not burn the hand when one whisks it through quickly. Designers addressed the problem of heating on the vehicle’s vulnerable underside by the simple expedient of using thicker metal construction to cope with anticipated thermal loads. Even these areas were limited in extent, with the contractors noting that "the material gauges (thicknesses) required for strength exceed the minimum heat sink gauges over the majority of the vehicle.”[1078]

McDonnell-Douglas went further. In mid-1971, it introduced its own orbiter, which lowered the staging velocity to 6,200 ft/sec. Its winged booster was 82 percent aluminum heat sink. Its selected configuration was optimized from a thermal standpoint, bringing the largest savings in the weight of thermal protection.[1079] Then, in March 1972, NASA selected solid-propellant rockets for the boosters. The issue of their thermal protection now went away entirely, for these big solids used steel casings that were half an inch thick and that provided heat sink very effectively.[1080]

Aluminum structure, protected by ablatives, also was in the forefront during the Precision Recovery Including Maneuvering Entry (PRIME) program. Martin Marietta, builder of the X-24A lifting body, also developed the PRIME flight vehicle, the SV-5D that later was referred to as the X-23. Although it was only 7 feet in length, it faithfully duplicated the shape of the X-24, even including a small bubble-like protrusion near the front that represented the cockpit canopy.

PRIME complemented ASSET, with both programs conducting flight tests of boost-glide vehicles. However, while ASSET pushed the state of the art in materials and hot structures, PRIME used ablative thermal protection for a more straightforward design and emphasized flight performance. Accelerated to near-orbital velocities by Atlas launch vehicles, the PRIME missions called for boost-glide flight from Vandenberg Air Force Base (AFB) to locations in the western Pacific near Kwajalein Atoll. The SV-5D had higher L/D than Gemini or Apollo did, and, as with those NASA programs, it was to demonstrate precision reentry. The plans called for cross range, with the vehicle flying up to 710 nautical miles to the side of a ballistic trajectory and then arriving within 10 miles of its recovery point.

The piloted X-24A supersonic lifting body, used to assess the SV-5 shape’s approach and landing characteristics, was built of aluminum. The SV-5D also used this material for both its skin and primary structure. It mounted both aerodynamic and reaction controls, the former consisting of right and left body-mounted flaps set well aft. Deflected symmetrically, they controlled pitch; deflected individually (asymmetrically), they produced yaw and roll. These flaps were beryllium plates that provided a useful thermal heat sink. The fins were of steel honeycomb, likewise with surfaces of beryllium sheet.

Most of the vehicle surface obtained thermal protection from ESA 3560 HF, a flexible ablative blanket of phenolic fiberglass honeycomb that used a silicone elastomer as the filler, with fibers of nylon and silica holding the ablative char in place during reentry. ESA 5500 HF, a high – density form of this ablator, gave added protection in hotter areas. The nose cap and the beryllium flaps used a different material: carbon-phenolic composite. At the nose, its thickness reached 3.5 inches.[1081]

The PRIME program made three flights that took place between December 1966 and April 1967. All returned data successfully, with the third flight vehicle also being recovered. The first mission reached 25,300 ft/sec and flew 4,300 miles downrange, missing its target by only 900 feet. The vehicle executed pitch maneuvers but made no attempt at cross range. The next two flights indeed achieved cross range, respec-

FILLER BAR. NOMCI PELT

FILLER BAR. NOMCI PELT

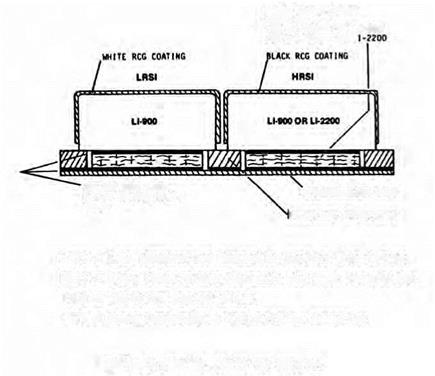

LRSI = Low Temperature Reusable Surface Insulation

HRSI = High Temperature Reusable Surface Insulation

RCG = Reaction Coated Glass

RTV = Room Temperature Vulcanizing Adhesive

INSTALLATION OF TILES ON SHUTTLE

Schematic of low – and high-temperature reusable surface insulation tiles, showing how they were bonded to the skin of the Space Shuttle. NASA.

tively of 500 and 800 miles, and the precision again was impressive. Flight 2 missed its aim point by less than 2 miles. Flight 3 missed by over 4 miles, but this still was within the allowed limit. Moreover, the terminal guidance radar had been inoperative, which probably contributed to the lack of absolute accuracy.[1082]

A few years later, the Space Shuttle brought the question of whether its primary structure and skin should perhaps be built of titanium. Titanium offered a potential advantage because of its temperature resistance; hence, its thermal protection might be lighter. But the apparent weight saving was largely lost because of a need for extra insulation to protect the crew cabin, payload bay, and onboard systems. Aluminum could compensate for its lack of heat resistance because it had higher

thermal conductivity than titanium. It therefore could more readily spread its heat throughout the entire volume of the primary structure.

Designers expected to install RSI tiles by bonding them to the skin, and for this aluminum had a strong advantage. Both metals form thin layers of oxide when exposed to air, but that of aluminum is more strongly bound. Adhesive, applied to aluminum, therefore held tightly. The bond with titanium was considerably weaker and appeared likely to fail in operational use at around 500 °F. This was not much higher than the limit for aluminum, 350 °F, which showed that the temperature resistance of titanium did not lend itself to operational use.[1083]