NASA 1958-1970: A Time of Transition

The transformation of the NACA into NASA in 1958 was marked by an inevitable subordination of the NACA’s aeronautical research charter to NASA’s mandated space mission work. The assigned aeronautics staff dropped over 80 percent, from 7,100 to 1,400, as the space program gained momentum in the early 1960s. In the new space – focused environment, aeronautics needed to be product-oriented to attract budget allocation support. In these circumstances, helicopter research lost ground as the focus shifted to new nonrotor Vertical Take-Off and Landing (VTOL) and Short Take-Off and Landing aircraft. In many cases, the rotary wing work formed the base for VTOL investigations. In the case of NACA-NASA rotor-flow studies, experimental and theoretical studies on rotor-time-averaged inflow led to extensive work on establishing wind tunnel jet-boundary layer (wall interference) correction methodology for other VTOL, as well as rotor – borne, lifting systems.[283]

In a sense, it became the U. S. Army’s turn to bolster NASA rotary wing endeavors in support of the Army’s need for continued helicopter development. In 1965, the Army was granted permission to reactivate, staff, and utilize the Ames 7- by 10-foot Tunnel No. 2. In addition, the Army provided personnel to assist Ames in carrying out projects of interest to the Army. A group of about 45 people was established by the Army and identified as the Army Aeronautical Activity at Ames (AAA – A).[284] In 1970, the working relationship between NASA and the Army was significantly enhanced. Co-located Army research organizations were established at Ames, Langley, and Lewis (now Glenn) Research Centers. They focused on the respective Center’s specialty of aeroflight dynamics, structures, and propulsion. This teaming laid the solid groundwork for major rotary wing programs that NASA and the Army jointly planned, executed, and funded in the 1970s and 1980s that influenced both military and civilian rotary wing aircraft development.

One of the unique research facilities authorized in 1939 and operated by the NACA, and then NASA, was the 40- by 80-foot Full-Scale Tunnel at Ames. This research facility also provided the opportunity to work directly with industry on vehicle development programs. In the case of rotary wing aircraft, the tunnel was utilized for investigating new vehicle and rotor system concepts and for thoroughly documenting the basic aerodynamic behavior of prototype and production articles. By the 1960s, numerous in-house and industry full-scale rotary wing hardware were tested. Examples include the Bell XV-1 "convertiplane” in 19531954, followed by many other projects, including a modified production rotor incorporating leading edge camber and boundary-layer control; the Bell UH-1 "Huey” helicopter (tested to assist in the development of a high-performance flight-test helicopter); a folded rotor with test data obtained in start-stop and folding conditions at forward speeds; and a four-bladed rotor investigation with extensive rotor-blade pressure measurements taken as a followup to prior flight test measurements made at Langley Research Center.[285]

The pressure-instrumented blade used in the latter tests had an extremely limited operating life of only 10 hours. This was because of the installation of nearly 50 miniature differential pressure transducers inside the rotor blade. This required that a total of almost 100 small holes be drilled in the upper and lower surface of the primary structure D-spar—normally an absolute "safety of flight” violation. The conservative 10-hour limit was based upon conservative crack-growth-rate limits determined from blade specimen cyclic load tests. The earlier flight test investigation of blade pressure distributions produced a very significant contribution as a primary database for the understanding of basic rotor unsteady aerodynamics. The tabulated pressure data provided time histories of individual differential pressures and simultaneous blade bending moments around the rotor azimuth in a wide assortment of steady and maneuvering flight conditions.[286] This database became the standard experimental data reference source for advancing theoretical comparison work for many years. As an aside, in working with the original flight data to hand-digitize the detailed recordings of differential pressure time-history traces, it became possible, in time, to visually recognize the specific flight-test condition by the periodic pressure trace signature.[287] It was possible to identify the rotor’s actual flight condition relative to the surrounding airmass. This still raises the question of the possibility of applying modern signal recognition technology to provide on-board safety-of-flight and noise abatement operating boundary displays for the pilot.

Flying qualities flight investigations emphasized the importance of ample damping of angular velocity and of control power (rotor-generated aircraft pitch and roll control moments) and their interaction. This work at Langley and similar work at Ames provided a significant portion of the helicopter flying qualities criteria. This early work was extended to the use of in-flight simulation using Langley’s YHC-1A tandem rotor helicopter with special onboard computing and recording equipment.[288]

|

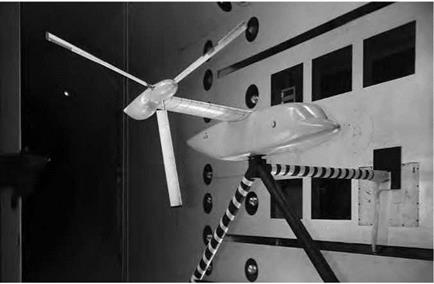

Tilt rotor semi-span dynamic model in the Langley Transonic Dynamics Tunnel. NASA. |

The flight operations of most interest were terminal area instrument flight on steep approaches to vertical touchdown landings. The results of this work were initially oriented to nonrotor VTOL operations, but the results were found to be equally applicable to helicopters.

In the area of structural dynamics, investigations addressing the problems of aeroelastic stability of rotor-powered aircraft were conducted utilizing new analytical methods and experimental studies by Langley and Ames researchers. Emphasis was placed on tilt rotor and tilt propeller (i. e., tilt wing) aircraft concepts. Two-degree-of-freedom "air resonance” (akin to rotor-fuselage "ground resonance”) and prop – rotor/propeller whirl instability were among the problems investigated.[289] Rotor-pylon-wing aeroelastic instability problems for tilt rotor designs were explored in the Ames 40 by 80 Full-Scale Tunnel in this period. The aeroelastic stability problems of the tilt rotor and tilt-stopped rotor designs were also investigated at model scale in the unique Freon atmosphere of the Langley Transonic Dynamics Tunnel, which provided full – scale Mach number and Reynolds number scaling.[290] These research

investigations resulted in significant contributions to the development of the validated design tools for advanced rotorcraft.

With the increased interest in hingeless rotor concepts, NASA obtained and quickly accomplished flight research with a copy of an experimental Bell Helicopter three-bladed hingeless rotor installed on an H-13 helicopter.[291] Early experience with "rigid” rotors had led the NACA to encourage interest in exploring the possibilities of removing conventional blade-root hinges and substituting instead blade structural flexibility. Another manufacturer, Lockheed Aircraft, made a major commitment to the hingeless rotor concept coupled to a mast-mounted mechanical gyro introduced into the pitch control linkage.[292] The root regions of the blades in this innovative design were "matched stiffness” or "soft in-plane,” which meant that the blade chord-wise, or horizontal, structural bending stiffness was matched to the flap-wise, or vertical, bending stiffness. Dynamic model tests of this concept were conducted in the Langley 30 by 60 Full-Scale Tunnel and in the Freon atmosphere of the Langley Transonic Dynamics Tunnel. The use of Freon gas facilitated the testing of the 10-foot-diameter rotor model at full-scale Reynolds number and Mach numbers. This work began the establishment of a documented database for hingeless rotor design. These dynamic model tests were part of a cooperative NASA-Army AVLABS program.

To further explore the problems and practical means for realizing the potential of the hingeless rotor concept, Langley Research Center purchased the Lockheed XH-51N, a high-speed research helicopter. The flight investigation focused on the tendency for hingeless rotors to encounter high in-plane blade loads in roll maneuvers, coupling between the response to longitudinal and lateral control input, ride quality, and pilot handling qualities. In general, it was demonstrated with the flight tests and model tests that the hingeless rotor system was different from the conventional hinged systems. Inherently, the hingeless designs produced increased control moments, quicker response to pilot input and superior handling qualities. It turned out that later rotor designs incorporating elastomeric bearings to replace conventional hinges could provide a practical option to some of the fully hingeless designs.