TECHNICAL ADVANCE IN AVIATION

The starting point for any discussion of technical advance in aeronautics is the landmark study of Ronald Miller and David Sawers, The Technical Development of Modern Aviation:66 One of the authors, David Sawers, had collaborated on an earlier and even more famous investigation, The Sources of Invention,67 In the latter work, Sawers and his co-authors had studied fifty cases in order to determine how industrial inventions arise in the modem world. A second edition added ten new case studies.68 Only two of the inventions, helicopters and the jet engine, were peripherally related to the aircraft manufacturing industry.69 Nonetheless, the general conclusions had wide applicability.

The study found a trend away from the lone inventor of previous ages to large, institutional sites. In these, creative genius counts for less than enlightened management. All are vulnerable to ossification as they grow large and old. Eclecticism usually triumphs over monolithic agendas and methodologies. There is no consistent relationship between monopoly and invention, but the patent system, for all its imperfections, remains important to the individual inventor or the small firm.

Miller and Sawers sought to test these conclusions in their investigation of aircraft development.70 What they found was an industry in which progress was not steady and incremental but rather episodic and pivotal. Writing in the late 1960s, amidst the U. S. policy debate over whether or not to proceed with development of a supersonic transport, Miller and Sawers found only ten aeronautical inventions after the Wrights and Curtiss to have been seminal. They are listed in slightly modified form in Table l.71 Others might argue for a longer list, but this one serves the purposes of this paper.

It also provides a chronology that helps to understand how and when aeronautics made its greatest advances. The Germans, say Miller and Sawers, made the greatest technical contributions. Partly for that reason, Europe led the United States in aircraft development until the late 1920s. Following Lindbergh’s flight, however, American aviation caught up quickly. The airframe revolution of the early 1930s, much of it based on German innovations, catapulted the United States into the lead in commercial airliners. While the Europeans devoted much of their attention to the development of fighter aircraft between the wars, the United States focused instead on bombers and long-range airliners, both powered by air-cooled engines and both placing a premium on range and payload. Depending in part on government-funded research for the military, the American aircraft industry achieved a 33% cost reduction in airliner operations between 1927 and 1933.72 The experience was repeated in the 1960s, when the first American jet airliners, the Boeing 707 and the Douglas DC-8, were introduced.

Miller and Sawers found what the previous Sources of Invention had found: there is no dominant pattern of technical development. While “technical progress… seems to have been rapid” in the aircraft industry, the inventions themselves came in many different ways.

![]()

|

|

|

|

Table 1.

Some were made in times of prosperity – which, for the aircraft industry, usually means war – and some in depression. Some were based on scientific discoveries; others were straight inventions based on the state of technical knowledge where any was appropriate, the recognition of need by an alert mind, or a more or less chance discovery.73

The aircraft industry itself produced a low level of invention; most ideas came from outside, many of them from universities and government laboratories.

Patents, say Miller and Sawers, “have rarely been important in the development of the airplane.”74 Advances in aerodynamic efficiency and supersonic flow, for example, do not often take patentable form. Manufacturers guard new designs as proprietary information until it is made public by incorporation on an aircraft. Outside inventors, in contrast, are reduced to seeking royalties from manufacturers on those developments, such as wing flaps, that are easily patentable. These conclusions highlight two characteristics of the patent system that ill suit it for aeronautical developments. It forces disclosure of information in exchange for protection and reward, a trade-off that some industries find disadvantageous. And it focuses more on mechanical artifacts than on designs and processes, which are central to aviation progress.

For these reasons and others, say Miller and Sawers, the aircraft manufacturers embraced the Manufacturers Aircraft Association and the patent pool. “The existence of the MAA,” they believe, “is mostly evidence of the unimportance of patents in the aircraft industry, but it reduces their importance still more.” Innovation has been important to the American aircraft industry, but patents have not. Furthermore, the patent pool has undermined the outside inventor by reducing the incentive of any single manufacturer to purchase rights to an invention. In the final analysis, however, “one cannot blame the MAA for the lack of invention in the American industry. It seems to be more an effect than a cause of this condition.” The proof of this, they believe, is that the British industry, which has no patent pool, has shown no greater inventiveness.75

Other analyses of the American aircraft industry have come to similar conclusions. John Newhouse, for example, attributes competition in the aircraft industry to operating efficiency, engineering integrity, configuration of aircraft, and price.76 As the industry has contracted down to fewer and fewer giant firms, there has been a tendency to associate innovation with survival. The continuous, incremental, cumulative refinement of aircraft design, usually conducted below the patent threshold, is often lost to view amidst these market forces.

Robert Ferguson’s exploration of World War II aircraft production in the United States reinforces these findings. He discovered that shop-floor practice and unpatentable, short-term, localized research often accounted for the technical gains made during the war.77 Companies did use patents, but primarily to establish postwar claims of primacy and to provide modest incentives for employees.78 For example, the Guerin patent for sheet-metal pressing of aluminum fuselage, described by one authority as “the greatest single contribution to the manufacture of all-metal airplanes,” was freely shared within the industry during the war, different manufacturers adapting it to their particular shop-floor practice and culture. “No two companies,” notes Ferguson, “designed or produced aircraft in exactly the same manner,” so that even when they used the same specifications, they often manufactured differently and produced slightly different products. For all these reasons, “during the war, patents did not play a significant role in the transfer of technology” in the aircraft industry.79

Nor do patents loom large in the case studies in aeronautical engineering that Walter Vincenti has used to explore What Engineers Know and How They Know /L80 It might be expected that patents would embody what engineers know and therefore play a large role in these stories. But “patent” does not appear in the index, and patents do not play a significant role in Vincenti’s analysis. They appear in his account of flush riveting, but mostly in the footnotes; patents seem to have little impact on the process that interests Vincenti most, the way in which knowledge of this important technique circulated within the aircraft manufacturing industry.81

Patents play a somewhat larger role in Vincenti’s account of the Davis Wing. Inventor David R. Davis invented an airfoil profile, which he then shopped around the aircraft industry. Davis creatively got around the disclosure aspect of patents by withholding from his patent application two unspecified, assignable constants, lacking which his formula was useless. The Davis wing came to be used on the 19,000 B-24 bombers built by Consolidated Aircraft in World War II.82 This, the largest production run of any bomber in history, no doubt enriched Davis and made him famous as well. But Vincenti doubts that the secret Davis wing section really contributed much to the great range achieved by the B-24. “High aspect ratio and other features of the airplane,” says Vincenti, have greater explanatory power.83 His larger point is that the real source of aeronautical development lies in the great diversity of engineering knowledge and the various ways in which that knowledge is accumulated and transferred.

Unlike Ferguson and Vincenti, Seymour Chapin addresses patents explicitly in his analysis of an important aeronautical technology, cabin pressurization.84 More precisely, he studies a costly and consequential struggle over patent interferences in the introduction of automatic rate-of-pressure change controls in the 1930s and 1940s. Patent interferences occur when two or more parties file patent applications for similar inventions that make overlapping claims. In this case, researchers at Boeing Aircraft Corporation and Douglas Aircraft Company filed patent applications for automatic rate-of-pressure change controls within two years of each other, in 1937 and 1939 respectively. Both were building on previous work that had been funded by the Army. Had the companies retained the rights to the patents, the dispute could have been handled within the Manufacturers Aircraft Association, where the arbitration board would have determined the licensing fee due to either or both of the companies. But Boeing granted licensing rights for its device to a new firm, AiResearch Manufacturing Company, which was not a member of the MAA. This dispute dragged through the Patent Office review system throughout the 1940s, finally to be decided in Douglas’s favor in 1950. AiResearch urged Boeing to appeal or to sue for reversal, arguing that it had already paid Douglas close to $1 million in royalties, with the prospect of still higher rates if the decision stood.

But Boeing had had enough. Patents were granted to both applicants, in 1951 and 1952 respectively, and Douglas’s device continued to win significant royalties. Boeing, of course, did not have to pay that market rate, for it was licensed to use the Douglas patent through the cross-licensing agreement. But AiResearch did have to pay, and Boeing had to forgo the royalties it would have received from AiResearch had its patent prevailed. Patents may not have played a major role in the technical development of American aviation, but they could still command significant sums of money in those instances where they did appear.

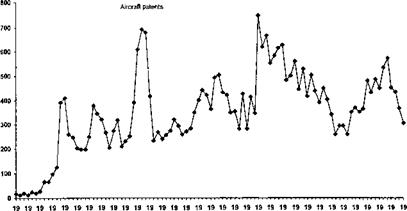

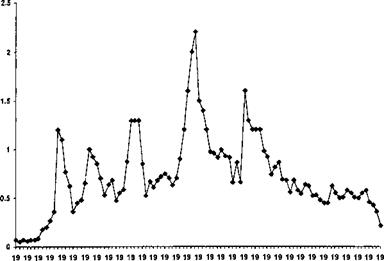

Analysis of U. S. aircraft patents from 1900 to 1996 reinforces the conclusions of these case studies. Figure 1, showing total aircraft patents, indicates no decline when the cross-licensing agreement was created nor any immediate increase when it was abolished. The steepest spikes accompany the public demonstrations of the Wright airplanes in 1908, the Lindbergh flight of 1927 and the airframe revolution of the early 1930s, and the introduction of commercial jet airliners in the late 1950s. When aircraft patents are taken as a percentage of total patents (see figure 2), different trends are revealed. Steep rises during the world wars indicate that other industries tended to decrease patenting activity during the wars more than the aircraft industry did. Furthermore, aircraft patenting has declined relative to other industries ever since the peak associated with the introduction of jet propulsion in commercial service. The overall patterns in these data confirm Miller’s and Sawers’ belief that major innovations in aviation have been few and far between. Most of the remarkable refinement of the modem airliner has come in small increments outside the patent system.

|

00 03 06 09 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75 78 81 84 87 90 93 96 Figure 1. U. S. Department of Commerce, Patent and Trademark Office, USPAT file, at North Carolina State University. Aircraft Patents are Classification Number 244. |

|

Aircraft patents as a percentage of total patents

00 03 06 09 12 15 18 21 24 27 30 33 36 39 42 45 48 51 54 57 60 63 66 69 72 75 78 81 84 87 90 93 96 Figure 2. U. S. Department of Commerce, Patent and Trademark Office, USPAT file, at North Carolina State University. Aircraft Patents are Classification Number 244. |

CONCLUSIONS

All the literature and all the data point to the same conclusion: patents have not been important in the development of aircraft manufacture in the United States. This answers some of the questions posed at the beginning of this study. Historians have neglected patents in aviation history because they did not play a large role after the early years. The patent pool appeared and survived because some such mechanism was needed in those early years, and it did little harm and perhaps some good thereafter.

But these conclusions leave unanswered the most vexing question: why was it that patents played so little role in the technical development of airframe manufacture, and what was driving that development? The answer to that question is complex and layered. It requires pulling together the findings of this study under five main headings.

First, the expectation that patents would play a role lacks warrant. Technical development does not necessarily depend upon, nor even correlate with, patenting. This is especially true in cumulative industries such as aircraft manufacture. In these cases, pioneering patents often dominate the field for a number of years. Thereafter, with the foundational ideas already introduced, the total body of knowledge at play is large and cumulative. New ideas are relatively less important. This seems to have been the case in aircraft manufacture. Technical development in this field has been continuous and significant, but it has proceeded incrementally below the patent threshold. Lucrative, important patents such as those for cabin pressurization devices, did appear from time to time, but they were comparatively few.

Second, airframe manufacture came to be conducted in a corporate environment increasingly less conducive to patenting. The industry gravitated from small companies reflecting the style and inventiveness of their founders to large corporations in which technical innovation flows from large, impersonal teams.85 Patents do issue from such institutions, but they are less important to these sponsors than they are to the lone inventor. Jacob Schmookler has found, for example, that as corporations grow larger, they pay more for research and realize fewer patents.86

Third, government funding of aeronautical research grew more important as the century proceeded. In universities and industry, as well as in its own laboratories, the government financed as much as 85% of aerospace research. Government and university laboratories were less inclined than industry and individuals to patent their developments. Even industry had less incentive to patent inventions made with government funds, for their contracts usually required free licensing to the government. Often the inventions of one industry contractor were shared freely by the government with others, further diminishing the value of patents.

This government-funded research, most often conducted under military auspices, was the principal way in which the United States subsidized aeronautical development. Many other countries adopted models of national airlines and research laboratories, directly supported by government funds. The United States eschewed such models, but found other, less obvious ways to support its aerospace industry. Research and development on military aircraft were often transferred to civilian aircraft, either through direct applications by companies such as Lockheed and Boeing that made both, or indirectly through publications such as NACA research reports that provided data applicable to both types of aircraft.87 This mechanism for the dissemination of research results became especially important during the Cold War, when aerospace research in the United States was driven by strategic and political considerations to be the best in the world. Spin-off from that research fueled the commercial aircraft industry throughout the second half of the century.

Fourth, in this competitive environment, companies often preferred proprietary knowledge over patents as a way of protecting their ideas. Indeed, patents were often avoided for the very reason that they made inventions public. An invention published in a patent could often be worked around faster by the competition than if it were kept secret until incorporated in an actual aircraft, whence the competition would have to reverse-engineer it, master its production, and redesign an existing plane to install it as a modification. As far back as the 1930s, aircraft manufacturers who came to NACA wind tunnels to test their aircraft and components were more interested in maintaining proprietary secrets than they were in patenting.88

Maintaining proprietary information in this industry was a difficult proposition. Aerospace engineers are mobile professionals. Companies can raid the staffs of their competitors to hire expertise and knowledge. Alternatively, some engineers may find themselves laid off, especially in the boom-and-bust atmosphere that came to surround the assignment of large contracts to increasingly fewer firms in the late Cold War. Furthermore, as aerospace engineering became more professional through the twentieth century, more and more members sought career advancement through publication. Walter Vincenti’s account of the development of flush riveting, for example, shows that even as companies and government employees were taking out patents on techniques of flush riveting, others were publishing the results of their research in the open literature. His account of the ways in which ideas about flying qualities circulated in the aeronautical community provides still more evidence of the multiple avenues of communication through which knowledge could travel.89 Keeping up on the state of the art, even as it advanced rapidly, was comparatively easy to do.90

But the free circulation of people and ideas did not mean that inventions in one firm were necessarily transferrable to another, at least not directly. Each of the major aerospace manufacturers developed a unique culture of management, design, and shop floor practice. So distinct were these cultures during World War II, that, according to Robert Ferguson, some firms could not replicate exactly the product of other firms even when they worked from identical specifications and plans.91 This points up the unusual tension between standardization and handcrafting that has always shaped aircraft manufacture. Aircraft defy the kind of automation that has overtaken, for example, the automobile industry. Airframes are still put together by hand, albeit in an assembly-line style. Therefore, shop floor practice leaves its imprint on the final product far more than in other standardized industries.92 Know-how from one environment might require considerable adaptation to work in another.

This last point emphasizes a fifth and final reason why aircraft manufacture came to depend less on patenting than might have been expected. Specific inventions in this field, in the form of devices, are often less important than design and process. In aircraft manufacture, production economies and competitive advantages are more often achieved through superior design and efficient manufacture than through superior components. The cabin pressurization devices studied by Chapin, for example, were similar in their effect and both were workable. The patent fight was not over which was better but which was first. When Douglas won that fight, Boeing simply worked around the patent to install on its aircraft a functionally comparable device. This sort of skirmishing, while it entailed significant royalty payments, was not the kind of development that accounts for the rise of Boeing or the decline of Douglas. It is possible to win patents for designs and processes, but companies seldom invested their energies this way. Rather, they developed their own style and relied on that to give them economic advantage in the marketplace. Real competitive advantage in the aircraft manufacturing industry came from practice, more than it came from patentable ideas.

As the aircraft manufacturing industry in the United States contracted over the course of the twentieth century, it became both more and less competitive. It was less competitive in the simple sense that there were fewer competitors. But it was more competitive in the sense that each remaining competitor was larger, had more resources, and risked more in a market with fewer buyers. The industry moved toward oligopoly while the market moved toward oligopsony.93 In such an environment, marketing and business decisions loomed larger; the price of the aircraft and its operation and maintenance counted for more than technical features, which tended to be similar across the industry. And as always, the single most important determinant of aircraft operating efficiency was the engine, a technology that always fell outside the cross-licensing agreement.

For all these reasons, patents have grown less salient in airframe manufacture than in U. S. industry in general (see figure 2). Individual decisions to seek a patent were no doubt shaped by these considerations and others, depending on particular circumstances. This account cannot begin to explain how those decisions were made. But it does provide some conceptual tools for thinking about aggregate patenting behavior in this field.