PRE-WAR EXCHANGE

Predating the wartime cooperatives were a number of formal and informal means for sharing technological information. The Manufacturers Aircraft Association (MAA) had since 1917 served as a means to pool critical aircraft patents. The MAA’s reach did not cover manufacturing technologies though. Nor did it have much influence on military designs, since during the interwar years the US Navy and Army Air Corps could award production contracts to any manufacturer they chose – regardless of the design’s origin. Though not the original intention of the military’s policy, this was a powerful means for spreading leading-edge aircraft design knowledge across the nation’s industry. Manufacturing knowledge, however, depended on more informal channels, occurring routinely through personal communication, trade journals, worker mobility, tooling manufacturers and raw material suppliers, and the occasional act of industrial espionage. It is to manufacturing knowledge that we turn our attention specifically, because it enlightens our understanding of the design and production process.12

One of the more dramatic exchanges of manufacturing knowledge, brought about in part through mobilization, was the large-scale introduction of presses. Job shop production methods of the 1930s involved the manual bending and shaping of sheet metal using brakes, shears, and drop hammers.13 Low production runs did not justify large capital expenditures merely to increase throughput. When orders from England, France, and eventually the United States became significant, and the number of skilled workers proved insufficient to the task, the manufacturers adopted mechanical and hydraulic presses which had long been in use in the automobile industry. Though the automobile industry provided a powerful model for mass production, many of its techniques could not be readily transferred without some measure of adaptation. In this case, not only did aircraft stampings require greater accuracy, but they were in a different material – sheet aluminum versus sheet steel. Aluminum is considerably softer than steel, and exhibits different stretch and spring-back properties. In short, the same equipment could not be universally used in the two industries.

In the late 1930s, Henry Guerin, a department head at Douglas Aircraft, arrived at a way to use hydraulic presses with rubber as one side of a die (Figure 2). Gordon Ashmead, who chronicled aircraft manufacturing techniques in the 1950s, described this innovation:

[The Guerin Process] has been the greatest single contribution to the manufacture of all-metal airplanes. The almost universal adoption of this method of forming sheet metal was the factor that lifted the forming of sheet metal out of the hand-forming category and placed it into mass production. Most airplane manufacturers give it credit for winning our air war.

While the use of rubber in forming dates to at least the 19th century, Guerin developed techniques that made it appropriate for the aircraft industry. The process substituted layers of rubber for the female half of a die. After workers positioned a sheet of aluminum over the male die, the press lowered the rubber pad and compressed it against the aluminum to the point that the rubber began to flow. The aluminum sheet formed to the male die as the rubber applied equal pressure over the entire piece. Guerin’s process was distinct from earlier methods in that the rubber was restricted to a box that fit tightly around the male die, preventing the rubber from escaping and increasing pressure on the aluminum.14

|

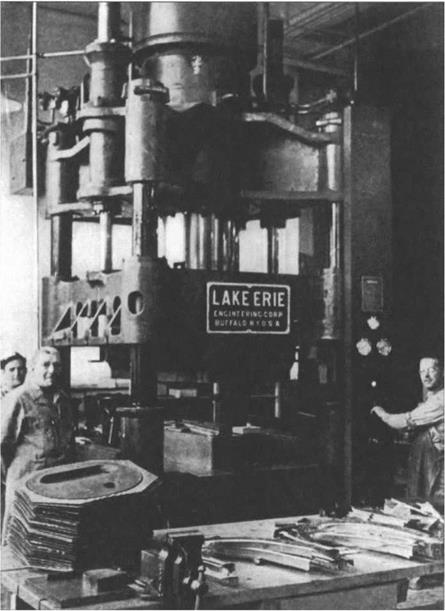

Figure 2. 600 Ton Hydraulic Press at Brewster Aeronautical Corporation. Chris J. Frey and Stanley S. Kogut, “The Use of Rubber for Producing Sheet Metal Parts’” Aero Digest 37 (December 1940), 147. |

The presswork championed by Detroit thus had to go through a translation before finding widespread application in the aircraft industry. The Guerin process would have been inappropriate for Detroit, where sheet steel would have quickly abraded the rubber. Not only was the Guerin process matched for aluminum, but it required only one metal die. At a time when tooling departments were working overtime to build jigs and fixtures, a fifty-percent reduction in diework was a welcome savings. Set-up time was reduced as well, since the rubber sheets did not have to be as accurately placed as a standard female die. Typically companies did not require many presses for the Guerin process, as a single large press with moving trays and 24-hour schedules could produce large quantities of stampings. In 1940, for example, Douglas operated a single 2,000-ton press with the Guerin process. As the war progressed, ever-larger presses came into use, including 5,000-pound presses with six work trays wherein a single shift could produce fifteen thousand parts. Ashmead indicates that the Guerin Process was most economical when quantities were between a few hundred and 50,000 parts – within the range typical of aircraft production. The Guerin process found widespread application throughout the airframe industry.15

The Guerin method is somewhat unusual in that most industrial processes were not patented at this time. Many processes were simply unpatentable, and so companies kept information proprietary through secrecy. Other processes, as noted, remained traditions of practice within a company’s tooling department. But even when a patent existed, as in the Guerin case, manufacturers quickly established distinct methods of using it, these too becoming part of local practice and forming a base of tacit knowledge within individual tooling departments. While Douglas’ patent on the innovation was sufficient to inform other manufacturers of the potential for such a process, it did not necessarily ensure good results. Surrounding the Guerin process arose a new body of engineering knowledge regarding its use, involving questions of press choice, die construction and arrangement, and appropriate pressures. The exchange of this accumulated tacit knowledge would eventually take place, but only after months and even years had elapsed, often traveling indirect routes between manufacturers. Typical of these indirect routes would be trade journals, tool manufacturers, and professional societies. In the case of the Guerin Process, representatives from Continental Rubber Works and Brewster Aeronautical (and later Eastern Aircraft – an aircraft division of General Motors) penned a series of articles on the many facets of the technique. Continental Rubber, though not strictly a tooling company, would obviously benefit from the adoption of the process. In this case Brewster and Continental Rubber surveyed different firms’ techniques and published them in Aero Digest, a leading trade journal of the time.16

It was not an uncommon practice for engineers and companies to champion particular techniques through articles and technical updates. With the outbreak of war, however, such indirect means of communication became difficult, as censorship restrictions limited the ability of trade journals to describe the latest technical advancements in detail. In some cases, the Army Air Force found itself reviewing material before publication; in many cases the resulting technical descriptions were so woefully vague that they could not have been of much assistance.17

Still, without other avenues, trade journals and user-producer relationships often provided the fastest pre-war means for accumulating and disseminating such esoteric information. Production and tooling information lacked the numerous channels of exchange that existed for other branches of aircraft technology. Tooling was not a subject for standardization within the Society of Automotive Engineers (SAE) or National Aircraft Standards Committee. As a practical art, tooling had no scientific component, and thus no society like the Institute for Aeronautical Sciences to pursue theoretical advancements. Not only were tooling patents excluded from the MAA, but the MAA agreement and military contracting policy intensified the importance of keeping production technologies proprietary. If significant aircraft design patents were to be shared under the MAA or transferred as part of a military design, it became all the more important to retain a competitive advantage in production techniques.