The X-15A-2

After Jack McKay’s emergency landing in X-15-2 on 9 November 1962, North American proposed modifying X-15-2 to an advanced configuration capable of reaching Mach 8 velocities. NASA in general and Paul Bikle in particular were not particularly enthusiastic and felt the Air Force should simply repair the aircraft to its original configuration or retire it altogether. Many researchers believed that the Mach 8-capable X-15A would be of limited value for aero-thermo research. However, NASA did not press its views, and on 13 May 1963 the Air Force directed North American to repair and modify the aircraft at a cost of $4.75 million. The advanced aircraft was intended to evaluate an air-breathing hypersonic research engine (HRE) being developed at Langley. It was designed to reach 8,000 fps at an altitude of 100,000 feet, and a dynamic pressure of 1,000 psf. Heating rates up to 210 Btu per square foot per second were expected, with peak structural temperatures approaching 2,400°F.[231

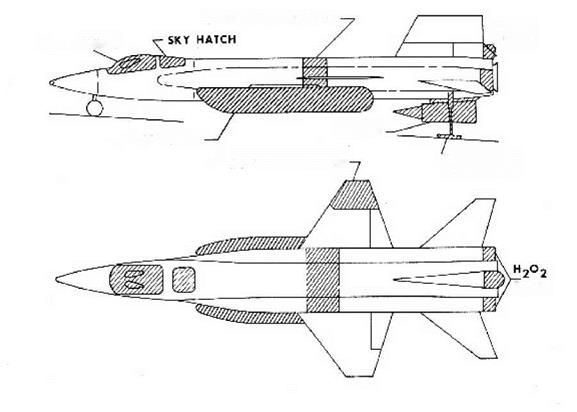

The modifications did not significantly alter the physical appearance of X-15A-2. The wingspan was still 22.36 feet, but the airplane was 29 inches longer due to a plug in the center of gravity compartment between the propellant tanks. Perhaps the most obvious change was the addition of external propellant tanks on each side of the fuselage below the wings. These allowed the airplane to carry approximately 70% more propellant, a necessary ingredient in raising performance to 8,000 fps. The tanks provided an additional 60 seconds of engine burn time, for a total of 150 seconds at 100% power. Other modifications included adding hydrogen-peroxide tanks within extended aft-side fairings to supply the turbopump for the longer engine burn times, and additional pressurization gas in a spherical helium tank just behind the vertical stabilizer.12321

The fuselage extension provided additional internal volume for experiments, and the center-of – gravity compartment access doors could accommodate optical windows looking up or down. The compartment could also accommodate a liquid-hydrogen tank, with a total capacity of 48 pounds, to fuel the ramjet mounted under the fixed portion of the ventral stabilizer, but it appears NASA never actually installed the tank. Perhaps the most difficult part of incorporating this extension was moving the B-52 pylon attach points to maintain the vertical stabilizer in the appropriate position under (through) the NB-52 wing.-12331

North American strengthened the landing gear using a strut that was 6.75 inches longer than the original. This provided 33 inches of ground clearance to the bottom of the fixed ventral stabilizer; the expected ramjet was 30 inches in diameter. The new strut provided a 1,000-pound increase in allowable landing weights, but there was some concern over the effects of the longer strut on nose-wheel and forward fuselage loads. In an attempt to provide an additional margin of safety, the nose-gear trunnion was mounted 9 inches lower (effectively lowering the nose gear by the same amount), allowing an attitude at nose-gear touchdown that was similar to that of the basic airplanes.12341

Instead of the trapezoidal windows on the original airplanes, North American installed elliptical windows that used three panes of glass to withstand the increased temperatures at Mach 8. The outer pane was 0.65-inch-thick fused silica, the middle pane was 0.375-inch alumino-silicate, and the inner pane was 0.29-inch laminated soda lime glass. This time the company mounted the outside windshield-retaining frame flush with the glass to prevent the reoccurrence of the flow heating experienced early in the program.-12331

The X-15A-2 modification also included a "skylight" hatch. Two upward-opening doors, 20 inches long by 8.5 inches wide, were installed above the instrument compartment behind the cockpit to expose cameras and other experiments. North American revised the normal research instrumentation elevator so that the upper shelf could extend upward through the open hatch if needed. The modifications also included additional data recorders: five 36-channel oscillographs, eight three-channel oscillographs, two 14-track tape recorders, one 24-cell manometer, and one cockpit camera. In addition, a new 86-channel PDM telemetry system was used to transmit data to the ground in real time.-12361

The accident had seriously damaged the outer portion of the right wing. North American found that it could adequately repair the main wing box, but the outer 41 inches were a total loss. With the government’s concurrence, the company modified the wing box to support a replaceable outer panel that allowed the testing of various materials and structures during hypersonic flight. The panel provided with the airplane (and the only one that apparently ever flew) was similar in construction and materials to the standard X-15 wing except that it was equipped with a 26.7 by 23-inch access panel that allowed access to an extensive amount of research instrumentation.-12321

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TANKS

After Jack McKay’s emergency landing at Mud Lake, the Air Force had North American rebuild the X-15-2 with several modifications intended to allow flights to Mach 8 to support ramjet propulsion research. The X-15A-2 was designed to reach 8,000 fps at an altitude of 100,000 feet, and a dynamic pressure of 1,000 psf. Heating rates up to 210 Btu per square foot per second were expected, with peak structural temperatures approaching 2,400 degrees Fahrenheit.

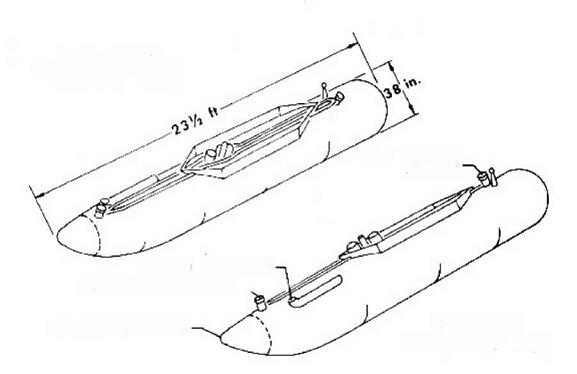

A 29-inch fuselage extension provided a larger center-of-gravity compartment to hold a liquid hydrogen fuel tank for the proposed ramjet, and external tanks carried additional propellants for the XLR99. (NASA)

NASA conducted wind-tunnel tests of the X-15A-2 during the summer and fall of 1963. The tests indicated that there was little aerodynamic difference between the modified X-15A-2 without external tanks and the basic X-15. Despite the anticipated similarities, engineers decided it was prudent to conduct an abbreviated flight series to verify that the airplane still handled satisfactorily. Stability and control maneuvers conducted during the initial flights of the X-15A-2 largely verified the wind-tunnel predictions. However, the verification took significantly longer than expected when the program encountered trouble with the modified landing-gear system.-1238

North American completed final assembly of X-15A-2 in Inglewood on 15 February 1964, and the Air Force accepted the airplane on 17 February, three weeks ahead of schedule and slightly below budget. The airplane was, however, 773 pounds overweight, a condition that was expected to reduce the maximum velocity somewhat. The design launch weight was 49,640 pounds, and propellants accounted for 32,250 of these pounds (18,750 pounds internally and 13,500 pounds in the external tanks). Subsequent modifications would add another few hundred pounds in empty weight. North American delivered the airplane to the FRC on 18 February and an "official" government acceptance ceremony took place on 24 February.-239

flight was to check out the various systems, evaluate the handling qualities of the modified airplane, and gain preliminary experience with the ultraviolet stellar photography experiment

(#1).[240]

It was not bad for a "checkout" flight. Using 77% thrust, Bob Rushworth reached Mach 4.59 and 83,300 feet. In an ironic twist, Jack McKay, who had been injured on the flight that damaged the airplane, was the NASA-1 controller. As expected, Bob Rushworth reported that the modified X- 15A-2 handled much like a basic X-15. Static longitudinal stability remained about the same, despite a 10% forward shift in the center of gravity. The already low directional stability of the unmodified airplane was somewhat lower in X-15A-2, but Rushworth did not think it posed a significant threat to safety. The longitudinal trim characteristics of the modified airplane were essentially unchanged up through Mach 3 at angles of attack up to 15 degrees. The modified airplane had a trim capability reduced by approximately 3-5 degrees at higher angles of attack and Mach numbers.*241

Things got more exciting on the second flight (2-33-56). Shortly after a maximum Mach number of 5.23 was obtained, the nose gear unexpectedly extended as the airplane decelerated through Mach 4.2. After the flight Rushworth wrote, "Everything was going along fine and just about the time I was ready to drop it over [lower the nose] I got a loud bang and… the resulting conditions that I had gave me quite a little bit of concern because the airplane began to oscillate wildly and I couldn’t seem to catch up with it. I put the dampers back on and stuffed the nose down to about 5 degrees angle of attack and it seemed to be normal then except I had a sideslip and I was then required to use left roll to hold the airplane level. A couple of seconds later I realized that this sound that I had heard was very much similar to the nose gear coming out in the landing pattern so that was the only thing I could think of. I announced that and then a few seconds later I began to get smoke in the cockpit, quite a little bit more than I had ever seen before. This partially confirmed that the nose gear, at least the door was open. I wasn’t sure that the gear was out but it was; there was enough of an explosion there to make me think that the gear was out."[242]

For the time being, the chase planes were of no help in confirming the problem since they were some 10 miles below the X-15. Jack McKay as NASA-1 could not help much either, since no emergency procedures existed for this particular failure. McKay did advise Rushworth that it would probably be best if the X-15 remained at high altitude until it had slowed considerably, thereby easing the aero-thermo loads on the extended nose gear. At one point NASA-1 advised Rushworth to use the brakes to slow down a bit, but Rushworth had other ideas: "No, I don’t want to get brakes out, I want to get the damn thing home." Fifty miles away from Edwards, the X-15 was still traveling at Mach 2.5 and McKay advised Rushworth, "Let’s go max L/D, Bob. You’re looking OK now. Your heading is good. You’re on profile. Looks like you’ve got plenty of energy."*241

The chase planes finally spotted the X-15 as it was descending 20 miles northeast of Edwards. Despite the degraded control and increased drag resulting from the extended nose gear, Bob Rushworth was doing fine. Joe Engle in Chase-3 verified that the nose gear appeared to be structurally sound and in the locked-down position. As for the tires, Engle reported, "OK, Bob, your tires look pretty scorched; I imagine they will probably go on landing." There was a worry, however, that the oleo strut had also been damaged by the heat and dynamic pressure; if it failed on landing, the X-15 could break in half or worse. There seemed to be little choice. Engle was right-the tires disintegrated shortly after the nose gear came down, but Rushworth managed to stop the airplane without serious difficulty.*244*

An investigation revealed that aerodynamic heating was the cause of the failure. The expansion of the fuselage was greater than the amount of slack built into the landing gear release cable. This caused an effective pull on the release cable that released the uplock hook. An outward bowing of the nose gear door imposed an additional load on the uplock hook. The load from both of these sources caused the uplock hook to bend, allowing the gear to extend. Engineers duplicated this failure in the High-Temperature Loads Calibration Laboratory by simulating the fuselage expansion and applying heat to the nose-gear door.[245]

The same stability and control data flight plan was duplicated for the next X-15A-2 light (2-3457) on 29 September 1964. Again, shortly after reaching a maximum Mach number of 5.20, Bob Rushworth experienced a similar but less intense noise and aircraft trim change at Mach 4.5-the small nose-gear scoop door had opened. In his post-flight report Rushworth noted, "Yes, I sensed it was the little door, because the magnitude of the bang when it came open wasn’t as large as the other experience." During the normal gear-extension sequence, air loads on the small door pulled the nose gear door open to assist in the extension of the nose gear. Although not as serious a failure as that on the previous flight, it again precluded obtaining dampers-off stability data. NASA redesigned the nose-gear door to provide positive retention of the scoop door regardless of the thermal stresses. Engineers also modified the other two airplanes since the basic failure mode was common.[246]

To check out the modifications to the nose gear, the program decided on a low-speed flight (235-60) to a maximum Mach number of 4.66. The flight planners decided to give Bob Rushworth a break after the two previous adventures, so Jack McKay made this flight, which went off without a problem. The nose gear performed normally.-12471

Rushworth was in the cockpit again for the next fight (2-36-63) of X-15A-2 on 17 February 1965. In a run of bad luck that is hard to fathom, this time the right main skid extended at Mach 4.3 and 85,000 feet. In his post-flight report Rushworth wrote, "Jack [McKay, NASA-1] was talking away and things were going along real nice and I couldn’t seem to get a word in there to tell him that I had a little problem. It took several seconds to get the airplane righted and dampers back on, very much similar to the nose gear coming out. Once I got it righted, I realized that I had a tremendous sideslip, I guess 4 degrees, and it took a lot of rudder deflection to get sideslip to zero. This persisted all the way down until I got subsonic. Once I had gone subsonic the airplane handled reasonably well." Again, the chase pilot was able to verify that the gear appeared structurally sound, and Rushworth managed to make a normal landing. When Rushworth finally got out of the airplane, he turned around and kicked it-enough was enough. Post-flight inspection revealed that the uplock hook had bent, allowing the gear to deploy. Again, aerodynamic heating was determined to be the source of the high load on the uplock hook.[248]

NASA flew five more X-15A-2 flights (2-38-66 through 2-42-74) before the envelope expansion program was begun. These flights were primarily conducted to study stability and control, but they also included landing-gear performance tests. Each flight carried the ultraviolet stellar photography experiment but obtained little useable data because of problems in maintaining the precise attitudes required for the experiment. Fortunately, the landing gear seemed to behave throughout these flights, but it had caused this portion of the flight program to take longer than expected.[2491

The engineers had always had some concerns about operating the X-15A-2 with the 23.5-foot – long, 37.75-inch-diameter external tanks. These attached to the airplane structure within the side fairings at fuselage stations 200 and 411. Propellant and gas interconnects ran through a tank pylon that was located between stations 317 and 397 and was covered by a set of retractable doors after the tanks were jettisoned. The left tank contained about 793 gallons of liquid oxygen in one compartment and three helium bottles with a total capacity of 8.4 cubic feet. The right tank contained about 1,080 gallons of anhydrous ammonia in a single compartment. The empty left tank weighed 1,150 pounds and the empty right tank weighed only 648 pounds; when they were full of propellants, they weighed 8,920 pounds and 6,850 pounds, respectively. Note that the left tank was over 2,000 pounds heavier than the right tank when they were full. To minimize weight and cost, the government had opted not to insulate the liquid-oxygen tank. As a result, the evaporation rate was high enough that the engineers considered the NB-52 top-off supply to be marginal. If a flight encountered a long hold time prior to launch, it might prove necessary to abort the mission and return to Edwards due to excessive liquid-oxygen boil – off.[250]

The use of external tanks on the X-15A-2 was unique in that the pilot had to jettison the tanks from the aircraft. The structural limitations of the aluminum tanks and the degraded handling qualities dictated that the maximum allowable Mach number with the external tanks was 2.6, so the pilot had to jettison the tanks before reaching that speed. In addition, a landing was not possible with the tanks installed because of the increased drag and a lack of ground clearance. Hence, the program expended considerable effort to ensure the tanks would jettison when commanded.-125^

Each tank was forcibly ejected from the airplane during flight through the use of fore and aft gas – cartridge ejectors and a forward solid-propellant sustainer rocket that imparted pitching and rolling moments to the tank after it had been ejected. For a normal empty tank jettison, both sets of gas cartridges fired and the nose rocket ignited. In the case of an emergency jettison when the tanks were full, only the nose gas cartridge fired.

The tanks were relatively expensive, so they were equipped with a recovery system that included a drogue and a main parachute. The drogue chute deployed from its nose compartment immediately after separation, and the main descent parachute deployed when a barometric sensor detected the tanks passing through 8,000 feet. Although the engineers expected some impact damage, they believed it was possible to refurbish the tanks at a reasonable cost.-252!

Wind-tunnel tests indicated that satisfactory separation characteristics existed when the dynamic pressure was less than 400 psf and the angle of attack was less than 10 degrees; acceptable separation probably existed for dynamic pressures up to 600 psf. At higher angles of attack and dynamic pressures, researchers expected the tanks to roll excessively and to pitch up within close proximity to the airplane. Tank separation characteristics with partly expended propellants were unknown and were a potential problem since there were no slosh baffles or compartments for center-of-gravity control. The researchers expected the full-tank ejection characteristics to be satisfactory for any reasonable flight conditions that might occur within 15 seconds of launch.-253!

Prior to the first flight using external tanks, the Air Force conducted two dummy tank jettison tests with X-15A-2 located over a 10-foot-deep pit in the ground beside the ramp. Technicians constructed a pair of beams with similar mass and inertia properties to simulate empty tanks. Preloaded cables attached to the beams applied simulated aerodynamic drag and side loads. The first test used a single set of ejector cartridges at simulated air loads of 400 psf, 5 degrees angle of attack, and 3 degrees of sideslip. The second test used two sets of ejector cartridges at a simulated dynamic pressure of 600 psf. Both tests were successful, and high-speed motion pictures showed good separation characteristics. During the tests, the X-15 APU supplied hydraulic and electrical power, and engineers engaged the SAS to observe its reaction to the separation, which was satisfactory.-2541

|

LEFT HAND LOX (3920 fb FULL)

LEFT HAND LOX (3920 fb FULL)

The external tanks allowed carriage of approximately 70 percent more propellant, a necessary ingredient in raising performance to 8,000 fps. The tanks provided an additional 60 seconds of engine burn time, for a total of 150 seconds at 100-percent power. The tanks were 23.5 feet long and 37.75 inches in diameter. The left tank contained about 793 gallons of liquid oxygen in one compartment and three helium bottles with a total capacity of 8.4 cubic feet. The right tank contained about 1,080 gallons of anhydrous ammonia in a single compartment. The empty left tank weighed 1,150 pounds and the empty right tank weighed only 648 pounds; when full, they weighed 8,920 pounds and 6,850 pounds, respectively. (NASA)

Despite this, during a review leading up to the first flight, engineers expressed concern over the possible separation of partially filled tanks during an emergency. The wind-tunnel tests and the tank separation system only covered full and empty scenarios. What would happen if the pilot had to abort the flight during the first 60 seconds of powered flight while the engine was siphoning propellants from the external tanks? The initial response was that the tanks, as designed, would not withstand the loads imposed during a separation with a partial load. Engineers at the FRC and AFFTC considered installing a rapid propellant-dump system, installing a set of baffles in the tanks, or even providing a system that would allow the pilot to refill the tanks using internal propellants. All seemed too complicated given the time and money available to the program.[255]

After a great deal of consultation among the engineers, flight planners, and pilots, management decided to continue, at least for the time being. The risk was considered reasonable because the XLR99 had never encountered a premature shutdown from 100% thrust-all failures had occurred either during ignition or while throttling. If a failure happened during ignition, the tanks would be full and would not present a problem, and the plan called for no throttling during the high-speed runs. Nevertheless, engineers decided to add a third jettison button in the cockpit. This one, intended for use with partial tanks, would fire the forward gas cartridge and ignite the separation rocket-sort of a middle ground between the other scenarios.-1256

Although there were physical differences between the basic X-15 and the X-15A-2 without external tanks, their aerodynamic qualities were similar. With external tanks on the airplane,

however, some rather dramatic differences existed, with the general trend toward unfavorable characteristics. The offset center of gravity caused by the external tanks further complicated the overall control task. At launch with full tanks, the vertical center of gravity was approximately 9 inches below the aircraft waterline, moving upward as the engine consumed propellants. The pilot had to use additional nose-up stabilizer trim to counteract the nose-down pitch at engine ignition caused by this offset below the thrust vector. The heavier liquid-oxygen tank on the left side displaced the center of gravity 2 inches to that side, causing a left rolling moment that the pilot also had to counteract.-257!

The nominal flight profile for the speed missions was to maintain the airplane at a 12-degree angle of attack until it reached a pitch attitude of 34 degrees. The pilot held this climb attitude until the external propellant was depleted. Tank ejection occurred at approximately Mach 2.1 and

67.0 feet, and the pilot maintained an angle of attack of 2 degrees until the airplane reached

100.0 feet. The airplane then accelerated to maximum velocity.258

As was the case with the basic airplane, the simulator predicted poor handling qualities at high angles of attack, due primarily to the large negative dihedral effect caused by the presence of the ventral rudder. For a yaw damper failure with the speed brakes out, a divergent sideslip oscillation persisted above 6 degrees angle of attack. Although the pilot could damp this divergence, it required almost continuous attention and left little time for other tasks. The simulator showed that turning off the roll damper would eliminate the divergent yaw oscillation, but then the pilot would have to fly the airplane with less lateral directional stability. From the simulator studies it was determined that, because of the relatively low-altitude profiles required, the airplane could be safely flown after a roll and/or yaw damper failure if an angle of attack of less than 8 degrees was maintained. The program accepted this restriction for the initial envelope expansion flights. However, for the projected ramjet tests, which required flights at high dynamic pressures, a divergence of this type could occur too rapidly for the pilot to take corrective action. Hence, NASA decided to provide a redundant yaw damper, similar to the ASAS used for the roll axis. The FRC began initial design work, but the flight program ended before the system was completed.-1259!

The final ground-based external tank test took place on the Rocket Engine Test Facility where X – 15A-2 had completed a full-duration engine run with the external tanks installed on the aircraft. Engineers had already corrected deficiencies uncovered during several earlier tests.268

The expected performance of X-15A-2 represented a significant improvement over the demonstrated 6,019 fps of the basic aircraft. With external tanks and the ventral rudder, the estimated velocity was between 7,600 and 7,700 fps at 120,000 feet. Replacing the ventral with an assumed ramjet configuration would decrease that to about 7,200 fps at 118,000 feet, a result of increased weight and drag for the ramjet configuration. This performance was, however, appreciably less than the design goal of 8,000 fps at 100,000 feet. As a result, Reaction Motors was investigating the development of a new injector and nozzle to provide additional thrust in an attempt to bring the performance back up to 8,000 fps. Again, the end would come before the company completed the work.261

The length of time the airplane could remain at high velocity and dynamic pressure determined the amount of useful data about the ramjet that could be obtained. Researchers expected that X – 15A-2 could stay above 7,000 fps for 50 seconds and above 6,000 fps for 110 seconds per flight. For ramjet tests that required steady conditions (that is, at a relatively constant velocity and dynamic pressure), the pilot would throttle the XLR99 to minimum and extend the speed brakes so that low acceleration existed. The expected stabilized test time for this configuration was approximately 14 seconds at 7,000 fps and 40 seconds at 6,000 fps.268

The first flight (2-43-75) with empty external tanks was on 3 November 1965, the only flight launched from Cuddeback, about 60 miles north of Edwards. Bob Rushworth jettisoned the tanks at Mach 2.25 as the airplane passed through 70,300 feet, and took the airplane to Mach 2.31 and 70,600 feet before landing at Rogers Dry Lake after a flight of only 5 minutes and 1 second (the shortest non-emergency powered flight of the program). Post-flight analysis indicated that the handling qualities were essentially as predicted by the simulator. Rushworth, who for a change was flying without deploying part of the landing gear, commented that he thought the "roll stability was significantly less than I had expected," but the "longitudinal control wasn’t quite as bad" as he had anticipated.-126^

Two ground-based mobile trackers, each with 150-inch lenses on 35-mm Mitchell cameras running at 72 and 48 frames per second, provided photographic coverage of the tank separation. In addition, six Askania tracking cameras recorded the tank recovery system. Because the events took place at quite a distance, the resulting image size was small and researchers could only make a qualitative analysis of the event. The tanks separated cleanly from the aircraft; however, it appeared that the tanks did not rotate nose down as much as expected. They exhibited a tumbling action during flight with the drogue chutes attached, and tended to trim at an angle of attack of about -110 degrees. The drogue chutes occasionally collapsed during flight, so the engineers lengthened the drogue chute riser for future flights. Impact with the desert destroyed the liquid-oxygen tank after the nose cone containing the main descent chute did not separate properly. The Air Force recovered the ammonia tank in repairable condition. The tumbling action of the tanks increased the total drag and the tanks fell short of their predicted impact points-the ammonia tank landed 2.3 miles short and 0.6 mile to the left, while the liquid-oxygen tank landed 2.7 miles short and 1.6 miles to the left. This was still well inside the bounds of the Edwards impact range and did not represent a problem.-264

Joe Engle ended up being the only X-15 pilot who would get to fly the next lifting-reentry vehicle, the Space Shuttle. He also has the distinction of being the only person to fly back from orbit, on the second Space Shuttle flight (STS-2). Milt Thompson said that "Joe Engle seemed to have a charmed relationship with the X-15" because for the most part all of Engle’s flights went according to plan. However, not everybody would agree with that assessment of his 15th flight.

On 10 August 1965, Engle took X-15-3 to 271,000 feet-his second flight above 50 miles.

Mission rules stated that the X-15 pilot should fly an alternate low-altitude mission if the yaw damper channel on the MH-96 failed during the first 32 seconds of flight. This was because it was unlikely the airplane could make a successful reentry with a failed yaw damper. On this flight (3-46-70), the yaw channel failed 0.6 seconds after the X-15 dropped off the pylon. Engle reset the damper and did not feel obligated to fly the alternate profile since the damper successfully reset. It was a temporary reprieve, however. The damper failed again 19 seconds later; the reset was successful for at least 10 seconds until it failed again. The damper failed three times in the first 32 seconds of flight. Remarkably, Engle successfully flew the mission, although he missed some of the profile for various reasons, including a preoccupation with resetting the failing yaw damper.264

At the end of 1965, NASA could see that the end of the X-15 program was in sight. Researchers had long since completed the originally envisioned basic flight research, and the aircraft were now primarily experiment carriers, although X-15A-2 was still extending the flight envelope somewhat. However, plans to use X-15A-2 as a hypersonic ramjet test bed began to unravel when, on 6 August 1965, Secretary of Defense Robert S. McNamara disapproved the funding necessary for the effort.266

Under the best-case scenario, the FRC anticipated that the flight program using the basic X-15s would begin winding down at the end of 1967 when X-15-3 began receiving its delta-wing modifications. By the end of 1969, X-15-1 would be retired, leaving only X-15A-2 and the newly redelivered delta-wing X-15-3 in service. X-15A-2 would finish its ramjet tests in mid-1970, transferring all flight activity to the delta wing.-267

Paul Bikle had long believed that any extended operation of the X-15 program beyond its original objectives was unwise and hard to justify in view of the high cost and risk involved. As early as 1961, he had suggested the end of 1964 as a desirable termination date. As time went on, Bikle felt that continued extensions of the program were becoming increasingly hard to justify, and he personally had strong doubts that either the delta wing or the HRE would ever reach flight status on an X-15. In spite of these personal misgivings, Bikle continued to support the program in his public statements.268

1965 FLIGHT PERIOD

January 1966 was much like December 1965 in the high desert-wet. Between 12 November and 1 December 1965 more than 3 inches of rain had fallen, and 2 more inches fell during December. NASA described Rogers, Three Sisters, Silver, and Hidden Hills as "wet," while Mud Lake was only "damp." Over 95% of Cuddeback was under water and there was visible snow at Delamar. A lack of landing sites effectively grounded the X-15 program.268

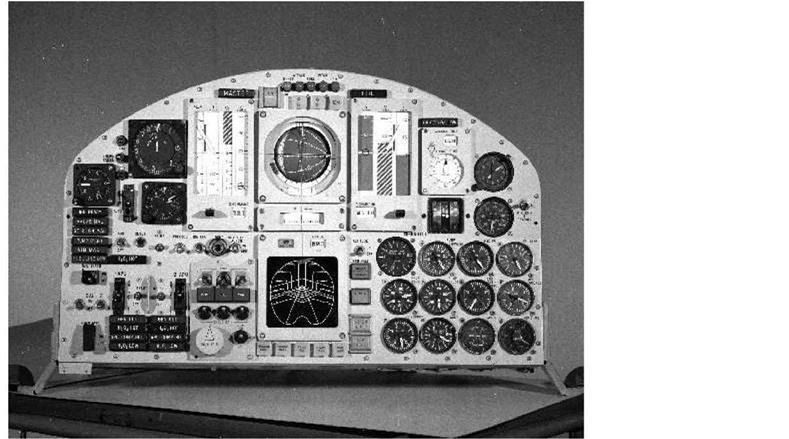

This gave the program time to do maintenance on the airplanes and incorporate various modifications. For instance, engineers installed the Honeywell IFDS, finally, on X-15-3 along with a new Lear Siegler-developed vertical-scale instrument panel. All of the instrumentation wiring on this airplane was removed and replaced with new four-conductor shielded Teflon wire. It received the modifications necessary to carry the wing-tip experiment pods, and the third skid and stick – kicker needed for higher landing weights were installed.278

The pilots were not greeting the new X-15-3 instrument panel with overwhelming enthusiasm. Paul Bikle opined that "there has been some evidence of reluctance to accept the vertical-scale, fixed-index [tape] instruments." Bikle noted that previously "no objective evaluation of the suitability of the panel for the X-15 mission had been made." To correct this, engineers installed a duplicate of the panel in the fixed-base simulator and conducted runs using "measurable flight control and pilot performance parameters in a comparison of the Lear panel with the traditional panel."278

Of all the performance measures taken, only two showed consistent and significant differences. These were the absolute error in velocity at power reduction and the burnout altitude; in both cases, the statistical results favored the Lear panel. An examination of the altitude and velocity indicators on both panels showed that the differences were the result of high-scale resolution on the Lear instruments, which was almost twice that of the traditional panel instruments. The pilots were still not altogether happy with the new panel, but they no longer mistrusted it.222

|

|

For most of the flight program, the X-15 used an instrument panel that contained conventional instrumentation. In 1965, Lear Siegler developed a new panel for X-15-3 that used vertical-scale instruments that were supposed to provide enhanced situational awareness for the pilot. Similar instruments were being incorporated into the latest generation of Air Force fighters about the same time. At first, the new instrument panel was not met with overwhelming enthusiasm from the X-15 pilots, but eventually they came to accept the new instruments, although having two very different cockpit configurations complicated the simulators and training regiments. (NASA)

During this down period, X-15A-2 received a new Maurer camera to replace the Hycon unit in the center-of-gravity compartment. This was not as simple as it sounded and took almost eight weeks of work. X-15-1 received a modification that allowed ground personnel to easily remove or replace the wing-tip pods as needed to support various experiments. NASA could now swap the pods between X-15-1 and X-15-3, and was manufacturing a second set of pods.[273]

As January passed with no relief from the wet lakebeds (another half inch of rain fell at Edwards, with more snow on the upper areas of the High Range), NASA performed more modifications on the airplanes. Because the increase in stiffness of the main skids and the addition of the third skid transmitted higher loads through the structure to the nose gear, engineers decided to reinforce the skin on X-15-1 between fuselage stations 91 and 106. The Air Force sent the NB-52B to Tinker AFB for major maintenance, leaving her older sister to support the flight program, assuming the lakebeds ever dried out. The carrier aircraft returned on 8 April and the AFFTC spent the next five weeks modifying it to carry the heavier X-15A-2.[274]

|

|

The X-15A-2 configuration was tested in a variety of wind tunnels, including one at the NASA Jet Propulsion Laboratory in Pasadena, California. The JPL tests centered around determining the effects of shock-wave impingement on the proposed ramjet and finding an alternate vertical – stabilizer configuration to provide enhanced stability at Mach 8 while carrying a ramjet under the ventral stabilizer. (NASA)

NASA also used the time to complete various analyses, including a complete simulation of reentry profiles at the increased weights currently flown by the airplanes. The ground rules were that reentries would be limited to 1,600 psf using an angle of attack of 20 degrees. To avoid exceeding the structural limitations of the airplanes, NASA decided to restrict X-15-1 to altitudes under 265,000 feet and X-15A-2 to less than 250,000 feet. Mostly because it was equipped with the MH-96, NASA allowed X-15-3 to operate up to 360,000 feet. These restrictions were not really a problem since the program had already reached the maximum altitude it was planning on, although the first two airplanes would bump into these limits on several future flights.-1275

The simulations showed that, as currently configured, X-15A-2 should be able to reach a maximum velocity of 7,500 fps without the ramjet and 7,100 fps with the ramjet, both at 120,000 feet. These velocities assumed a launch weight of 51,650 pounds with the use of external tanks and an XLR99 burn time of 152 seconds. Based on these simulations, flight planners decided to conduct the X-15A-2 envelope-expansion program with the ventral on, primarily because it most closely resembled the planned ramjet configuration. However, the program was short of ventral rudders, and it was uncertain whether economic constraints would allow each flight to use one.-1275

More importantly, Langley and the Jet Propulsion Laboratory conducted wind-tunnel tests to investigate shock-wave systems affecting the proposed ramjet installation on X-15A-2. Researchers worried that shock waves impinging on the ramjet could affect inlet and engine performance, structures, and structural heating. The tests provided data for angles of attack between -5 and +20 degrees at Mach numbers between 2.3 and 4.63. A review of the data

showed that a shock wave emanating from the forward tip of the landing-gear skid would impinge on the ramjet inlet at all Mach numbers, and did not significantly vary with the angle of attack. These tests also showed that there was a complex shock impingement around the ventral stabilizer in general. Apparently, these data went unnoticed.-1272

By the beginning of April, the weather had improved considerably. The Air Force was in the process of repairing and re-marking Rogers, Grapevine, and Mud Lake. Cuddeback was dry but still too soft to re-mark. All of the other lakes were drying rapidly and were ready to use by the end of the month.-1278-