High-Temperature Loads Calibration Laboratory

The requirement to measure flight loads on aircraft flying at supersonic and hypersonic speeds led the FRC to construct the High-Temperature Loads Calibration Laboratory in building 4820 during 1964. The facility allowed researchers to calibrate strain-gage installations and test structural components and complete vehicles under the combined effects of loads and temperatures. The laboratory was a hangar-type structure with a small shop and office area attached to one end. A door measuring 40 feet high and 136 feet wide allowed access to an unobstructed test area that was 150 feet long by 120 feet wide and 40 feet high.222

|

|

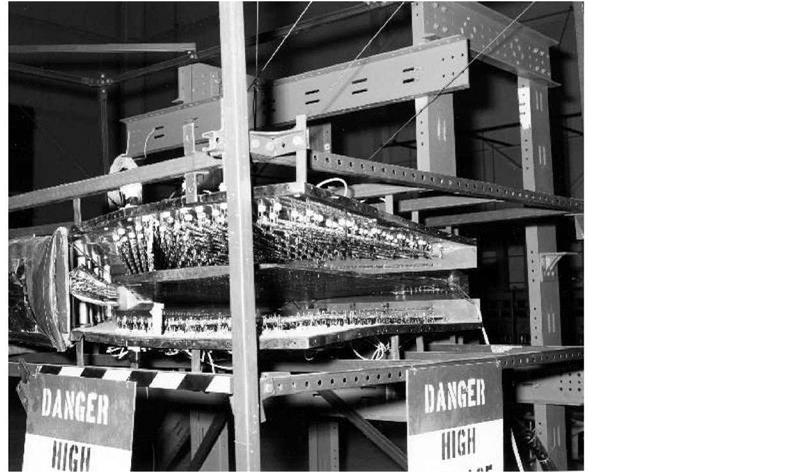

The High Temperature Loads Calibration Laboratory was established at the Flight Research Center to allow researchers to calibrate strain-gage installations and test structural components and complete vehicles under the combined effects of loads and temperatures. The facility was equipped with a programmable heating system that used infrared quartz lamps available in various lengths from 5 inches to 32 inches. Reflector arrangements were available for heating rates from 0 to 100 Btu per second per second and temperatures up to 3,000 degrees Fahrenheit. This photo shows an X-15 horizontal stabilizer being tested under the lamps. (NASA)

A state-of-the-art control room was provided to operate the heating and loads equipment remotely, and a data acquisition system occupied the second floor over the office spaces. Large windows overlooked the hangar floor, and the room included a closed-circuit television system. A high-capacity hydraulic system could operate up to 34 actuators to apply loads to test specimen or entire aircraft. Perhaps more importantly for the X-15 program, the facility had a programmable heating system that used infrared quartz lamps available in various lengths from 5 inches to 32 inches. Reflector arrangements were available for heating rates from 0 to 100 Btu per second per second and temperatures up to 3,000°F.[223]

NASA used this facility for a variety of purposes during the remainder of the flight program. This included testing a set of X-15 horizontal stabilizers as part of the loads program undertaken late in the flight program, and the laboratory proved to be critical for solving the inadvertent landing- gear extension problem suffered by X-15A-2 when it began its envelope expansion program. NASA later used the laboratory to test portions of the XB-70A and Lockheed Blackbirds.