REACTION MOTORS XLR11

In order to get flight-testing under way, North American completed the first two aircraft with interim Reaction Motors XLR11-RM-5 engines. Two XLR11s were installed in each aircraft, producing a total of 11,800 lbf at sea level. These engines were quite familiar to personnel working in the experimental rocket aircraft programs at Edwards, since the Bell X-1, Douglas D – 558-2, and Republic XF-91 all used the same powerplant (or its XLR8 Navy equivalent).-1132!

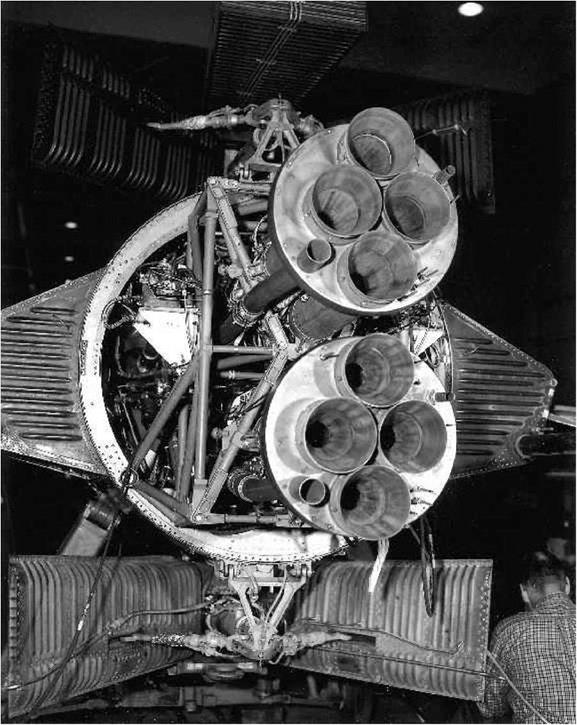

The basic XLR11 configuration was called G6000C4 by Reaction Motors and consisted of four thrust chambers producing 1,475 lbf each with a turbopump unit, valves, regulators, and controls mounted forward of the chambers. Other variants of the XLR8/XLR11 family used pressure-fed propellants instead of a turbopump. The four chambers were mounted on a support beam assembly that was the main structural member of the engine. A single turbopump provided the pressure to inject the liquid-oxygen and ethyl-alcohol-water propellants, while valves in the oxidizer and fuel lines controlled the flow of the propellants to the chambers. Each thrust chamber contained an igniter, and the pilot could ignite or shut down individual chambers in any sequence, allowing a measure of "thrust stepping." However, once the pilot shut down a chamber, he could not restart that chamber. Fuel circulated through passages in each exhaust nozzle and around each combustion chamber individually for cooling, and then into the firing chambers to be burned. Each engine weighed 345 pounds dry (including pumps) and was approximately 60 inches long, 36 inches high, and 24 inches wide. On paper each engine (including the turbopumps) cost about $80,000, although technicians at Edwards assembled all of the engines used in the X-15 program on site from components left over from earlier programs.-133!

It was surprisingly easy to install the XLR11 in the X-15, considering that the designers had not intended the aircraft to use the engine. Part of this was due to the mounting technique used for the XLR99: the engine was bolted onto a frame structure, which was then bolted into the engine compartment of the aircraft. A new frame was required to mount the two XLR11 engines, but the structural interface to the aircraft remained constant. However, the XLR11 used ethyl alcohol – water for fuel instead of the anhydrous ammonia used in the XLR99. This necessitated some modifications to the system, but none of them were major-fortunately, the two liquids had a

similar consistency and temperature. Surprisingly, no documentation describing the changes seems to have survived; however, as Scott Crossfield remembers:[134]

[S]ince the XLR11 engines were installed as two units including their own fuel pumps, the X – 15 needed only to supply the tank pressures to meet the pumps inlet pressure requirement and the engines didn’t know what airplane they were in. There were, of course, structural changes, i. e., engine mounting and I believe some ballast but nothing very complex. That is a relative statement. The difference in mixture would make the ideal fuel/lox load different but I don’t remember that was a significant problem.

|

|

forms, in the Bell X-1 series, Douglas D558-2, and Republic XF-91 programs at Edwards AFB. All of the engines used for the X-15 were made from leftover components from earlier programs. (NASA)

Charlie Feltz remembers that there were no modifications to the fuel tanks. North American had already built and sealed them by the time NASA decided to use the XLR11s. It was determined that both the metal and the sealant were compatible with alcohol, so there was no need to reopen the tanks. There were some minor changes to the plumbing and electrical systems to accommodate the new engines, along with cockpit modifications to provide the appropriate instrumentation and controls.-11351 Nevertheless, considering that North American had designed the airplane with no intention of installing anything but the XLR99, the changes were of little consequence and did not materially delay the program.-11361

In the final installation, the two engines were mounted on a single tubular-steel mounting frame attached to the airplane at three points. The mount canted the upper engine slightly nose-down and the lower engine in a slightly nose-up attitude so that their thrust vectors intersected at the airplane’s center of gravity.-11371

After the last XLR11 flight, NASA placed the remaining engines, spare parts, and special tools into long-term storage. Despite being almost 20 years old, the engines later found their way into the heavyweight lifting bodies.11381