STABLE PLATFORM DEVELOPMENT

Another major piece of government-furnished equipment was the all-attitude inertial system, called a "stable platform" at the time. Early on, researchers realized the performance of the research airplane required a new method to determine altitude, speed, and attitude information. The original Langley study, as well as each of the contractor proposals, had suggested the use of a stable platform. Unfortunately, such as system was not readily available.

A meeting held at Wright Field on 14-15 November 1955 implied that the WADC would furnish the stable platform. Arthur Vogeley, the NACA representative, assumed that the Air Force had already developed a suitable device since his report stated that a newly developed Bendix platform weighed only 28 pounds and occupied less than a cubic foot of volume. Others within the NACA and North American were not as certain. During a meeting with North American personnel, Walt Williams specifically asked who was responsible for the stable platform, and no answer was immediately forthcoming.-1145!

Researchers apparently did not discuss the requirements for a stable platform until 24 May 1956 during a meeting at Langley. In attendance were representatives from Eclipse-Pioneer (a division of Bendix), the NACA, North American, and the WADC. This group discussed the platform mentioned at the November 1955 meeting, and Eclipse-Pioneer acknowledged that it was only a conceptual design and not a forthcoming product. Nevertheless, the meeting attendees thought

that development of a suitable platform would take only 24 months. Since the platform provided research data in addition to flight data, the NACA agreed to charge 40 pounds of the estimated 65-pound weight against research instrumentation. There was no mention as to why the original 28-pound estimate had grown to 65 pounds.-146

Despite its early participation, Eclipse-Pioneer did not exhibit any further interest, so the Flight Control Laboratory asked the Sperry Gyroscope Company if it was interested. By August 1956, Sperry had prepared a preliminary proposal, and on 4 October the X-15 Project Office held a technical briefing for Sperry at Wright Field.147

On 26 December 1956, the Flight Control Laboratory began the process to procure eight inertial flight data systems (six "Type A" units for the X-15 and two "Type B" units for ground research). The laboratory recommended awarding the $1,030,000 contract to the Sperry Gyroscope Company.-1148!

For unexplained reasons, the Air Materiel Command did not take immediate action and did not release a formal request for proposal to Sperry until 6 February 1957. Two weeks later Sperry replied, and the Flight Control Laboratory approved the technical aspects of the proposal on 28 March. In the meantime, however, a controversy had developed over contracting details. The negotiations reached a deadlock on 11 April 1957 and the Air Materiel Command informed the X – 15 Project Office that it intended to find another contractor. The Flight Control Laboratory and X – 15 Project Office argued that Sperry was the only company that stood a chance of meeting the X – 15 flight schedule, but procurements were the domain of the Air Materiel Command and the warnings fell on deaf ears.-1149!

It was evident that the issue was rapidly exhausting the patience of all concerned. On 22 April 1957, the director of development at the WADC, Brigadier General Victor R. Haugen, informed the Air Materiel Command that Sperry was the only company capable of developing the stable platform within the schedule constraints of the X-15 program. Having a general officer intervene was apparently the answer, and a cost-plus-fixed-fee contract signed on 5 June 1957 provided $1,213,518.06 with an $85,000 fee.156

Because of the contracting delays, the expected December 1958 delivery of the initial Sperry unit would not support the first flight of the X-15. This was not a significant problem since the initial X-15 flights would be low and slow enough to use a standard NACA flight test boom to provide the data ultimately supplied by the stable platform and ball nose. In fact, the NACA would likely have used the flight test boom even if the other instruments had been available, since it provided a known, calibrated source for acquiring initial air data. Most experimental aircraft use similar booms during early testing.151

More disturbing, however, was that it quickly became apparent that the weight of the stable platform had been seriously underestimated. In May 1958, Sperry undertook a weight-reduction program that, unfortunately, was particularly unsuccessful. By August, Sperry was reporting that the weight was approximately twice the original specification.157

It was just the beginning of serious trouble. By June 1958, the estimated cost was up to $2,741,375 with a $105,000 fee. Less than a year later the cost reached $3,234,188.87 with an $119,888 fee, mostly due to efforts to reduce the weight of the stable platform.157

specification, the system weighed 185.25 pounds. An alternate shock mount that did not meet the requirements but was probably acceptable brought the weight down to 165.25 pounds. Interestingly, Sperry admitted it had known about the weight problem for some time, but did not explain why it had not brought the issue to the government’s attention at an earlier date.-1154

Sperry defended its actions by listing the changes it had made to eliminate excess weight. These included substituting aluminum for stainless steel in some locations, reducing the thickness of various covers, and reducing component weight wherever practical. The need to include power supplies not anticipated in the original proposal also increased the weight of the system. Finally, Sperry also concluded that the stable platform was lighter and more accurate than any competing system. Apparently, Sperry’s justification was satisfactory since the X-15 Project Office accepted that the system was going to remain overweight and took no further action on the subject.[155]

As finally delivered, the stable platform was an Earth-slaved, Schuler-tuned system aligned in azimuth to a guidance vector coincident with X-15 centerline. The unit provided attitude, velocity, and altitude to the pilot with reference to these coordinate systems. There were three major components to the stable platform: the stabilizer, computer, and displays. Together they weighed approximately 165 pounds, occupied about 3 cubic feet of volume, and required a peak electrical load of 600 W. The stabilizer used three self-balancing accelerometers and three single-degree – of-freedom gyroscopes. A four-gimbal system provided complete attitude freedom in all axes.

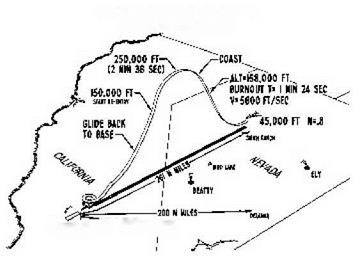

An analog computer computed velocity and position data, and applied the necessary acceleration corrections. The computer was shock-mounted and shaped to conform to the contours of the X – 15 instrumentation compartment. Gaseous nitrogen from the X-15 cooled the stabilizer and computer to counteract the internal heat generated by the units, and the extreme external temperatures. The system was "designed to operate over a limited portion of the Earth’s surface." Specifically, it could accept a launch point anywhere within a 275-mile-wide corridor extending 620 miles uprange and 205 miles downrange from Edwards AFB.[156]

Sperry shipped the first stabilizer and computer to Edwards in late January 1959, and the Air Force intended to use the NB-52 carrier aircraft as a test vehicle. This was delayed for unknown reasons, so the Air Force made a KC-97 that was already being used for similar purposes by the Convair B-58 program available to the X-15 project. The first flights in the KC-97 took place in late April, but were of limited value given the low speed of the piston-powered Stratocruiser. In June 1959, North American successfully installed the Sperry system in X-15-3 prior to its delivery to Edwards. By the end of May 1960, there were four complete stable platforms at Edwards: one in X-15-1, one in X-15-3, one spare, and one undergoing repair.-1157

As delivered, the stable platforms could provide the following data:[158]

|

Measurement |

Range |

Accuracy (rms) |

Display |

Record |

|

Pitch angle (degrees) |

unlimited |

0.5 |

V |

V |

|

Roll angle (degrees) |

unlimited |

0.5 |

V |

V |

|

Yaw angle (degrees) |

unlimited |

0.5 |

V |

V |

|

II——————— II—————————— II————— ІГ |

|

Altitude (feet) |

0-500,000 |

5,000 |

V |

|

|

Total velocity (fps) |

7,000 |

70 |

V |

|

|

Downrange velocity (fps) |

7,000 |

50 |

V |

|

|

Crossrange velocity (fps) |

3,000 |

50 |

V |

|

|

Vertical velocity (fps) |

5,000 |

20 |

V |

However, Sperry had made several compromises during the development of the X-15 stable platform, either to meet schedule or reduce weight. The designers knew that 300 seconds after launch (i. e., as the airplane decelerated to land) the pressure instruments would be adequate for vehicle altitude and velocity data, and that a system capable of operating from carrier aircraft takeoff to X-15 landing would be too heavy and bulky for the X-15. The final design had a very limited operating duration. The pilot aligned the system just before the X-15 separated from the NB-52, and the stable platform provided just 300 seconds of velocity and altitude data, along with 20 minutes of attitude data. This limited operating duration provided some relief for the weight problem.-115^

As it turned out, the lighter shock mount developed by Sperry was not adequate for the X-15. It performed fine during the XLR11 flights, but vibration tests in October 1960 prior to the beginning of XLR99 tests showed that the mount would not withstand more than 1.5 g at 110 cycles. North American redesigned the mount, since by this time saving weight had become a non-issue for the most part; having a reliable airplane was worth more than the few miles per hour the weight cost.

Over the course of the flight program, the stable platform was the subject of several other changes that greatly improved its reliability. Many of these were the result of suggestions from John Hursh at the MIT Instrumentation Laboratory and Dr. Allen Smith from Ames, both of whom spent a great deal of time at the Flight Research Center during late 1960 working on the problems. As an example of these changes, NASA changed all critical germanium transistor amplifiers to silicon during November 1960. NASA also made changes to operating procedures as well as to hardware. Initially, a gyroscope failure required that the entire stable platform be returned to Sperry for repair, taking the unit off flight status for three to six weeks. In response, the FRC developed an in-house repair capability that significantly shortened turnaround times. Even better, during late 1960 NASA substituted a higher-quality gyroscope manufactured by Minneapolis-Honeywell, which resulted in fewer failures.-1160

|

|

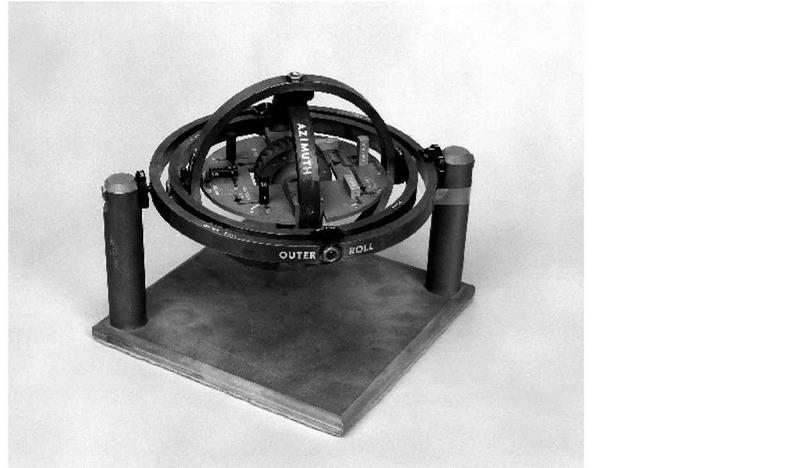

The X-15 was one of the first aircraft to require what is today called an inertial measurement unit, or stable-platform. Gyroscopes of the era were large, heavy, and consumed a considerable amount of power. This model shows the three interlocked rings required to determine position in three dimensions. (NASA)

In retrospect, the performance specifications established in 1956 were well beyond the state of the art with respect to available gyros, accelerometers, transistors, and circuit techniques.

However, the system as originally built was able to perform at levels that, although marginal or subpar compared to the original specification, still allowed the X-15 to realize its full performance capabilities. Compared to modern laser-ring-gyro and GPS-augmented systems, the X-15 stable platform was woefully inaccurate, but it routinely bettered its 70-fps error specification for velocity. Initially its altitude-measuring ability was somewhat substandard, averaging about 2,200 feet (rms) uncertainty. The requirement was 2,000 feet, but the system eventually improved and met its specification. Reliability was initially poor, but by mid-1961 the overall reliability was approaching the high 90th percentile, with the altimeter function proving to be the most unreliable. Unfortunately, this improved reliability proved to be short-lived.-1161

The initial operational experience with the stable platform showed that it had a large error potential that grew as time passed from the initial alignment due to drift and integration noise. The unit integrated velocities to provide distance (X, Y, and Z) and specifically altitude, which had even more error buildup with time. Early flight tests showed that the displayed velocities were marginal even after the 90-second engine burn, and that the altitude was undependable for determining peak altitude or reentry setup. Because of this, the flight planners and pilots began to consider two other sources for controlling the energy imparted to the airplane: 1) engine burn time, as measured by a stopwatch in the NASA-1 control room, and 2) radar-measured velocity,

[1621

as displayed in the control room.

For the first government flight (2-13-26) with the XLR99 engine, the flight planners decided to use radar velocity as the primary indication with a radio call to Bob White at the desired engine shutdown condition. After the successful flight, researchers calculated that the airplane had exceeded the intended speed by about half a Mach number. Further analysis showed that the radar velocity display in the control room incorporated considerable smoothing of the data to provide a readable output. This introduced a lag of 4 seconds between the actual speed and the displayed speed, thus accounting for the overshoot. For the next few flights, NASA-1 started a stopwatch in the control room at the indication of chamber pressure on the telemetry, and radioed the pilot when it was time to shut down the engine.-163

Using a stopwatch to measure powered flight time proved to be the simplest and yet most accurate method of controlling energy, so a stopwatch was installed in the cockpit of all three airplanes. A signal from the main propellant valves started and stopped the stopwatch so that it displayed the total burn time even after shutdown. The pilot could then assess whether he had more or less energy than planned, and evaluate his energy condition and best emergency lake in the event of a premature shutdown. Although the reliability of the stable platform increased considerably during the course of the program and was eventually operating within its design specifications, the pilots continued to use the stopwatch (with a backup stopwatch in the control room) for most flights. It was cheap and easy, and almost never failed.164

By 1963 an increasing number of stable platform failures began to occur—some because of design deficiencies, others simply due to component deterioration. This led to NASA placing a new set of restrictions on X-15 flights, keeping them below 160,000 feet. Progress by Sperry to resolve the issues was slow, so an analysis was undertaken at the FRC to determine what in-house efforts could be made to bolster system performance and improve reliability.163

Beginning in late 1963, the FRC began redesigning critical components to improve both accuracy and reliability. Eventually, NASA engineers redesigned some 60% of the subassemblies in the stable platform. Overall, the volume used by the accelerometers, accelerometer electronics, and power supplies was reduced over 50%, and an accompanying reduction in power and cooling requirements was also realized. Although some of the improvements resulted from correcting deficiencies in the original design, most were achieved because the state of the art had improved considerably in the four years since work had begun. NASA completed the initial redesign efforts on the accelerometer loops and power supplies during the summer of 1964, and the first flight of the new components was in X-15-2 on 14 August 1964 (2-33-56). Technicians subsequently installed the revised components in X-15-3 also. This system allowed NASA to cancel the 160,000-foot altitude restriction on the airplanes.

Although the initial performance of the revised components was a little erratic, the increase in accuracy was substantial. For instance, 400 seconds into the flight the original system would have a +8,000-foot error in altitude; the revised system generally had a -1,000-foot error. (In both cases the specification required a less than -5,000-foot error; nothing on the positive side was satisfactory.) Eventually the engineers tuned the erratic performance out of the system. By May 1966, components designed at the FRC had essentially replaced the entire Sperry stable platform, and the system was redesignated the "FRC-66 Analog Inertial System."166

and a set of pilot displays. This system was even smaller and required less power and cooling than the redesigned FRC-66 analog system. In addition, the X-20 IFDS could automatically erect itself and perform an alignment cycle on the ground while the NB-52 was taxiing, and completely eliminated the need for information from the N-1 compass and APN-81 Doppler radar on the NB – 52. This made it somewhat easier to pilot the carrier aircraft as the X-15 approached the launch position; the APN-81 took 90 seconds to stabilize after even a gentle turn, requiring the NB-52 pilot to think well ahead of the drop time. To improve accuracy, however, the IFDS altitude loop was synched to the NB-52 pressure altimeter until 1 minute before launch.-1167

and a set of pilot displays. This system was even smaller and required less power and cooling than the redesigned FRC-66 analog system. In addition, the X-20 IFDS could automatically erect itself and perform an alignment cycle on the ground while the NB-52 was taxiing, and completely eliminated the need for information from the N-1 compass and APN-81 Doppler radar on the NB – 52. This made it somewhat easier to pilot the carrier aircraft as the X-15 approached the launch position; the APN-81 took 90 seconds to stabilize after even a gentle turn, requiring the NB-52 pilot to think well ahead of the drop time. To improve accuracy, however, the IFDS altitude loop was synched to the NB-52 pressure altimeter until 1 minute before launch.-1167

The inertial measurement unit was a gyrostabilized, four-gimbaled platform that maintained local vertical orientation throughout the flight. The inner platform contained three pendulous accelerometers that formed an orthogonal triad. The coupler electronics unit contained the power supplies and interface equipment, and a dual-function digital computer performed all computations. NASA first checked out the digital system in X-15-1 on 15 October 1964 (1-5079), with satisfactory results.1168

The overall performance of the IFDS during its first 16 flight attempts was excellent, with only two failures. However, problems with the IFDS caused two attempted launches in a row (1-A-105 and 1-A-106) to abort during June 1966. After the first abort, technicians replaced a relay and fixed a loose wire, but the second flight attempt a week later ended the same way. Engineers from Autonetics (a division of North American), Honeywell, the FRC, and Wright Field began investigating the problem. The failures were determined to be the result of yet more wiring problems, all easily corrected.-168

JH5 RESEARCH SYSTEM

TYPICAL MISSION

![]() KtmiuiUtei

KtmiuiUtei

I ill!

Because of limitations in both the gyroscopes and onboard computers, the X-15 stable platform could only function for a limited amount of time in a 275-mile-wide corridor extending 620 miles uprange and 205 miles downrange from Edwards AFB. Later modifications to the system were more reliable and versatile, and at the end of the program, two of the X-15s were using digital inertial flight data systems developed for the Air Force Dyna-Soar program. (NASA)

At the same time, the installation in X-15-3 was not going as well as it had in X-15-1. On 6 January 1965, representatives from Honeywell met with FRC personnel to discuss problems with the installation. There were four primary concerns: cooling and thermal conditions, space availability, cabling, and the interface to the MH-96 adaptive control system. This latter issue was surprising since the X-20 also used a version of the MH-96. Also discussed was the relative accuracy expected from the new system versus data from the ball nose. It was pointed out by the

Honeywell representative that at low velocities there would be a significant difference between the IFDS-computed angle of sideslip and that sensed by the ball nose, but at high velocities the difference should be small.[170]

By April 1965 the FRC had made little progress installing the system in X-15-3, and only X-15-1 was flying with the Honeywell inertial system. Fortunately, by this time the modified Sperry systems were proving to be reliable, and no substantial problems had been experienced by X-15- 2 or X-15-3 since December 1964. Engineers finally installed the Honeywell IFDS in X-15-3 during a weather-induced down period at the end of 1965.-1171

Although the Honeywell IFDS was considered an improvement over the modified Sperry stable platform, the FRC decided that the FRC-66 system was preferred for the Mach 8 flights in the modified X-15A-2, so that airplane never received an IFDS. By the end of 1965, engineers had modified one of the Sperry computers to have Mach 8 scaling coefficients in preparation for the X-15A-2 envelope-expansion program.-1172

The improvements did not stop there. Eventually the FRC modified X-15-3 to include an Ames – developed guidance system that was applicable to future aerospace vehicles. This system coupled the IFDS inertial system, MH-96 adaptive control system, and ball nose to an Alert digital computer to investigate boost guidance command techniques. The navigation functions continued to be performed by the inertial system while the Alert computer handled the research objectives, including providing new displays to the pilot. This program allowed the pilot to fly a velocity – altitude window during boost, a bounded corridor during hypersonic cruise, and a precise corridor during reentry. It was an advanced system, and one that Space Shuttle only duplicated in its waning years.-1173