ESCAPE SYSTEM DEVELOPMENT

The development of an escape system had been the subject of debate since the beginning of the X-15 program. North American’s decision to use a combination of an ejection seat and a full – pressure suit was a compromise based largely on the ejection seat being lighter than the other alternatives. It was also heavily lobbied for by Scott Crossfield.

The Aero Medical Laboratory had recommended an escape capsule, as prescribed by existing Air Force regulations, as early as 8 February 1955. However, the laboratory admitted that an escape capsule would require a long development period and would probably be unacceptably heavy. The laboratory’s alternative was an ejection seat with limb restraints used together with a full – pressure suit. Meetings held during October and November 1955 resulted in a direction to North American to develop an ejection seat that would incorporate head and limb restraints. The Air Force also told North American to document the rationale for adopting such a system.!1281

Privately, Scott Crossfield had already decided he did not like capsule designs. Part of this came from experience with the Douglas D-558-2 program. According to Crossfield, "We had a capsule nose on the Skyrocket but knew from the wind-tunnel data that if you separated the nose from the fuselage, the g-force would be so great it could kill you. I made up my mind I would never use the Skyrocket capsule. I would ride the ship down and bail out." Later events with a similar system on the X-2 would prove this fear correct.!1291

The North American analysis of potential accidents that could cause the pilot to abandon the X – 15 produced some surprising results. Despite the high-altitude and high-speed nature of the mission profiles, North American determined that 98% of potential accidents were likely to occur at dynamic pressures below 1,500 psi, Mach numbers below 4.0, and altitudes less than 120,000 feet. Using these as criteria, North American investigated four potential escape systems: fuselage – type capsules, cockpit capsules, encapsulated seats, and open ejection seats. The comparison included such factors as cockpit mobility, escape potential, mechanical reliability, post-separation performance, and airframe compatibility. This effort took some 7,000 man-hours to complete.

The results showed that an open ejection seat imposed the fewest performance penalties on the aircraft and took the least time to develop. The estimates from North American showed that a satisfactory escape capsule would add 9,000 pounds to the 31,000-pound airplane. Just as importantly, North American—and Scott Crossfield, who would be making the first flights in the airplane-believed the ejection seat offered a better alternative in the event of an emergency, mainly due to its relative mechanical simplicity.-1130!

Despite the report, the Air Force was not completely convinced. During a meeting at Wright Field on 2-3 May 1956, the laboratory again emphasized the perceived limitations of ejection seats. Primarily due to the efforts of Scott Crossfield, the Air Force finally agreed that "the X-15 was probably its own best capsule." The meeting also resulted in another action for North American, once again, to document its rationale for selecting the stable-seat and full-pressure suit combination.-131!

North American held the first formal cockpit inspection in July 1956 at its facility in Inglewood. This inspection featured a fully equipped cockpit mockup, complete with instruments, control sticks, and an ejection seat. The seat was a custom design that featured a new type of pilot restraint harness and small stabilizers to "weather-vane" it into the wind blast and prevent fatal tumbling or oscillation. A solid rocket motor provided about 3,000 lbf to ensure that the seat would clear the X-15. Despite Air Force policy to the contrary, nobody raised any objections about the seat during the inspection. By default, it became part of the official design.-132!

By November 1956, North American had tested a 0.10-scale isolated pilot-seat model of its design in the Naval Supersonic Laboratory wind tunnel at the Massachusetts Institute of Technology (MIT). Although the seat seemed to stabilize randomly in different orientations, the results were generally encouraging. In itself, this did not represent a serious problem, although all participants wanted to understand the dynamics involved. North American conducted additional tests in the Southern California Co-Operative Wind Tunnel in Pasadena to develop the final stabilization system configuration and determine the influence of the forward fuselage without the cockpit canopy.-133!

The debate over the X-15 ejection seat intensified on 27 September 1956 when Captain Milburn G. Apt was killed in the X-2. However, the accident also weakened the case for an escape capsule. The X-2 used a semi-encapsulated system whereby the entire nose of the aircraft, including the cockpit, was blown free of the main fuselage in an emergency. Unfortunately, Bell engineers had expected the pilot to be able to unbuckle his seat straps and manually bail out of the capsule after it separated, something Apt was unable to do. It demonstrated that an encapsulated system was not necessarily the best solution, but then neither was an ejection seat. Almost by definition, piloting X-planes was—and would remain—a dangerous occupation.134

During early 1958, researchers began testing the X-15 ejection seat on the rocket sleds at Edwards, with the preliminary runs concluding on 22 April. The series got off to a good start, with the first test seat ejected at 230 knots and the parachute successfully opening at 120 feet, lowering the anthropomorphic dummy gently to the ground. The dummy was equipped with telemetry that relayed data from rate gyros, accelerometers, and pressure transducers. The second test, this one at 620 knots and a dynamic pressure of 1,130 psf, also went well. The third test, under similar conditions, was again satisfactory. However, during the fourth run the shockwave generator catapult exploded at Mach 1.26 and 2,192 psf. The accident damaged the seat, suit, and anthropomorphic dummy beyond repair. Engineers fired another seat during a static test on 24 April, but the post-ejection operation failed because of a mechanical problem in the initiation hardware. During the second static test on 14 May 1958, the parachute and parachute lines became tangled with the seat. In all, the test series provided mixed results. North American made several minor modifications in preparation for a second series of tests scheduled for June.-1135!

The high cost of the rocket-sled runs, coupled with the damaged seat hardware, was quickly exceeding the budget for the escape-system tests. Because of this, the X-15 Project Office decided to conduct only two tests, at 125 psf and 1,500 psf. Despite the earlier difficulties, Air Force and North American engineers believed these two tests could adequately demonstrate seat reliability.-1136!

The Air Force conducted the test at 125 psf on 4 June 1958, and the results appeared to be satisfactory. Three successful tests took place during June, but the fourth test, on 3 July, revealed serious stability problems. North American discontinued further tests until it could determine a cause for the failures. A detailed analysis revealed that the seat would need several major modifications.-137!

The Air Force conducted the first test of the revised North American seat on 21 November 1958, but several of the sled rockets failed to ignite and reduced the desired 1,500-psf pressure to about 800 psf. Two tests during December also suffered from the failure of sled rockets. The only test conducted during January failed when the right-hand boom and fin failed to deploy. The leg restraints also failed during the test, but North American believed an instability caused by the boom malfunction caused this. The parachute failed to open until just before the test dummy hit the ground, causing significant damage to the dummy.138!

|

|

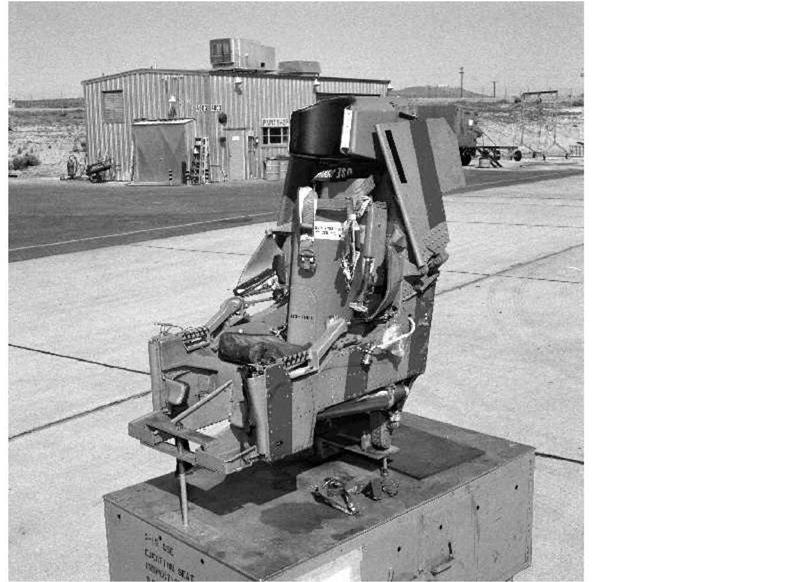

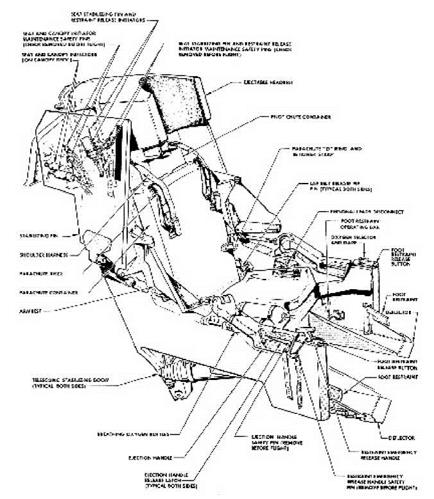

The ejection seat for the X-15 was a remarkable engineering achievement, and was the most sophisticated ejection seat yet developed at the time of the first X-15 flight. Still, it was much simpler than an encapsulated ejection system would have been. (U. S. Air Force)

The schedule was getting tight since the X-15 was nearly ready to begin captive-carry flights. On 12 January, the Aircraft Laboratory verbally approved the seat for the initial captive and glide flights between Mach 0.377 and Mach 0.720 at dynamic pressures between 195 and 715 psf. The X-15 Project Office considered this satisfactory given the inability of the NB-52 to go much faster.^

|

|

As developed by North American, the ejection seat contained provisions to restrain the pilot’s arms and legs to keep them from flailing in the airstream after leaving the aircraft, and also booms and canards to stabilize the seat during separation. After the seat left the aircraft, the pilot unbuckled and jumped from the seat, coming down on his own parachute. (North American Aviation)

Because of the unsuccessful January test, North American carefully rechecked and strengthened the booms and pressure-tested the seat’s gas system. The Air Force conducted the final sled-test on 3 March 1959 at Mach 1.15 and 1,600 psf—conditions somewhat in excess of requirements. Despite the failure of the leg manacles, the test was the most successful to date. North American proposed additional tests and a parachute program in April 1959, but the X-15 Project Office was happy with the results of the tests already run and declined. The X-15 finally had an ejection seat.^1401

The pilot used a backpack-type parachute after he separated from the seat. However, because of the design of the pressure suit, seat, and cockpit, neither the Air Force nor North American considered the standard quarter-deployment bag and 28-foot-diameter C-9 parachute acceptable. Instead, North American produced a special 24-foot-diameter chute and "skirt bag" specifically for the X-15. The company extensively tested this combination on a whirltower to verify the design of the skirt bag, the optimum pilot-parachute bridle length, and the effect of having the seat headrest permanently attached to the pilot chute. The tests in early 1958 included opening speeds up to 300 knots, and subsequent free-fall tests with an anthropomorphic dummy released from a Fairchild C-119 Flying Boxcar over the National Parachute Range in El Centro, California. During the initial tests, the C-119 released the dummy in a head-down attitude at 125

knots and 1,200 feet. These tests were unsuccessful because the pilot chute deployed into a low – pressure zone in the wake of the dummy and was not capable of pulling the main chute from the pack. North American extended the bridle length to 70 inches, allowing the pilot chute to escape the low-pressure area, and subsequent tests were successful.-141

Initially North American used the 24-foot diameter chute because it was the largest they could easily accommodate in the backpack and the engineers thought it would open more quickly, allowing safe ejection at lower altitudes. However, several flight surgeons had concerns that it would allow too high a descent rate for the pilot, and urged the certification of a larger parachute for use on the X-15. During October 1960, North American tested a repackaged 28-foot – diameter parachute at the National Parachute Range. These tests were successful and indicated no significant difference in opening time between the smaller and larger chutes. It became policy that each pilot could select whichever size parachute he wished to use. Most continued to use the 24- foot chute because the reduced thickness of the backpack made it more comfortable to sit on in the cockpit.142

In June 1965, NASA authorized North American to purchase five new 28-foot parachutes to replace the 24-foot units that had reached their 7-year service limit. The new chutes had a disconnect device that allowed the pilots to release one-half of the shroud lines during descent. They were less comfortable because they were thicker than the original parachutes, but as personnel at Edwards discarded the smaller units, they became standard.142

Despite the confidence Scott Crossfield and the North American engineers had in the ejection seat, apparently it was not universal. Pete Knight once commented, "They tell me that the seat is good for Mach 4 and 120,000 feet. I take it with a grain of salt, but I think the safest place to be is inside the airplane until we get to a more reasonable environment…. If you had to, as a last resort certainty you would take the chance, but I think most of the pilots have felt that we…would stay with [the airplane] as long as possible." At least everybody agreed that the cockpit was a safe place. Crossfield demonstrated that when the X-15-3 exploded on the ground while he was testing the XLR99 engine.-144-

|

|

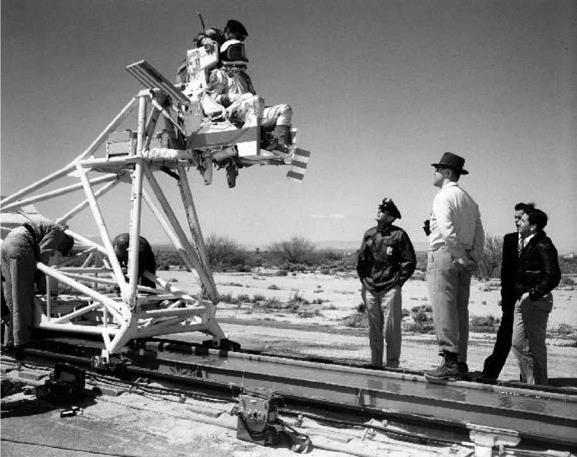

The X-15 ejection seat, like all other seats of the era, was tested on the rocket sled track at Edwards AFB, California. The sled test results were mixed, with many failures of both the sled and the seat for various reasons, but ultimately the Air Force, NASA, and North American were satisfied that the seat would work as advertised. (U. S. Air Force)