Conflict and Innovation

Although it gave the appearance of having a rather simple configuration, the X-15 was perhaps the most technologically complex single-seat aircraft yet built. The airplane would require the development of the largest and most sophisticated man-rated rocket engine yet, and a heated debate took place regarding the escape system for the pilot. Given the extreme environment in which it was to operate, engineers had to either invent or reinvent almost every system in the airplane. North American’s Harrison A. "Stormy" Storms, Jr., and Charles H. Feltz had a difficult job ahead of them. Both men were widely admired by their peers, who considered them among the best in the business (a fact confirmed much later when both men played key roles during the development of the Apollo spacecraft).

Harrison Storms had studied aeronautical engineering under Theodore von Krmn at the California Institute of Technology during the 1940s before joining North American Aviation. He was chief engineer for the entire Los Angeles division, and although he was greatly interested in the X-15 he had other responsibilities that precluded daily contact with the X-15 program. Nevertheless, he would be a powerful ally when bureaucratic hurdles had to be overcome or the customer needed to be put at ease.-11!

Feltz had joined the company in 1940, working on the P-51 Mustang and B-25 Mitchell during World War II, and later the B-45 Tornado and F-86 Sabre. As the X-15 project engineer, Feltz would lead the day-to-day activities of the design team. In those days at North American, the project engineer was in charge of the entire work force assigned to his airplane. Surprisingly, the 39-year-old Feltz had never heard of the X-15 until Storms pulled him off the F-86 program to be the project engineer, meaning that he had not been involved in the proposal effort and needed to catch up. Fortunately, Storms and Crossfield were there to help.[2]

|

|

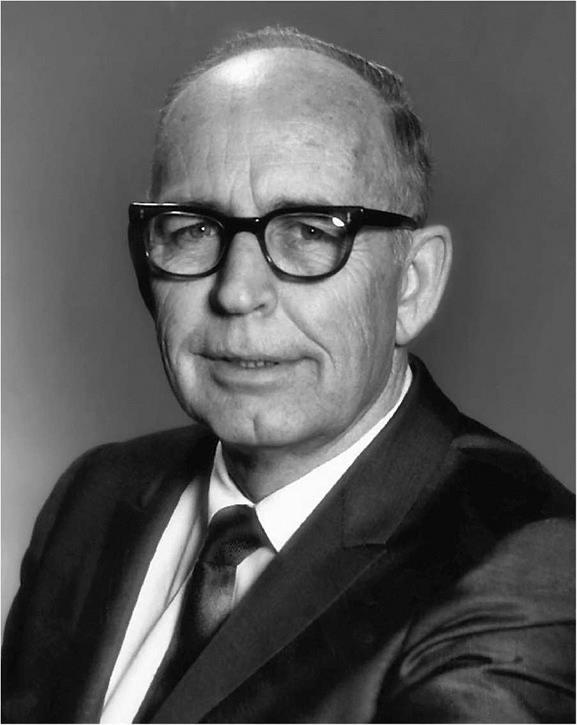

Charles H. Feltz had joined North American Aviation just before the beginning of World War II and had worked on several high-profile projects prior to being assigned as the lead of the X-15 development effort. Feltz would go on to lead North American’s Apollo Command and Service Module and Space Shuttle efforts. (Boeing)

Directly assisting Storms and Feltz was the already legendary NACA test pilot A. Scott Crossfield, who had joined North American specifically to work on the X-15. Crossfield had been a Navy instructor pilot stationed at Corpus Christi, Texas, during World War II before receiving a bachelor of science degree in aeronautical engineering and a master’s in aeronautical science from the University of Washington. Crossfield describes Storms as "a man of wonderful imagination, technical depth, and courage…with a love affair with the X-15. He was a tremendous ally and kept the objectivity of the program intact.." According to Crossfield, Charlie Feltz was "a remarkable ‘can do and did’ engineer who was very much a source of the X-15 success story." In 2001, Crossfield called Feltz "the flywheel of common sense engineering who educated the world with the X-15, Apollo, and the Space Shuttle.’,[3]

The day Crossfield reported for work at North American, he defined his future role in the program. As he recounted in his autobiography, "I would be the X-15’s chief son-of-a-bitch. Anyone who wanted Charlie Feltz or North American to capriciously change anything or add anything…would first have to fight Crossfield and hence, I hoped, would at least think twice before proposing grand inventions." He played an essential role, for instance, in convincing the Air Force that an encapsulated ejection system was both impractical and unnecessary. His arguments in favor of an ejection seat capable of permitting safe emergency egress at speeds between 80 mph and Mach 4, and altitudes from sea level to 120,000 feet saved significant money, weight, and development time. Crossfield also championed the development of a full- pressure suit for the X-15 pilot. f4!

There has been considerable interest in whether Crossfield made the right decision in leaving the NACA, since it effectively locked him out of the high-speed, high-altitude portion of the X-15 flight program. Crossfield had no regrets: "I made the right decision to go to North American. I am an engineer, aerodynamicist, and designer by training…While I would very much have liked to participate in the flight research program, I am pretty well convinced that I was needed to supply a lot of the impetus that allowed the program to succeed in timeliness, in resources, and in technical return.. I was on the program for nine years from conception to closing the circle in flight test. Every step: concept, criteria, requirements, performance specifications, detailed design, manufacturing, quality control, and flight operations had all become an [obsession] to fight for, protect, and share—almost with a passion." Crossfield seldom lacked passion.[5!

|

|

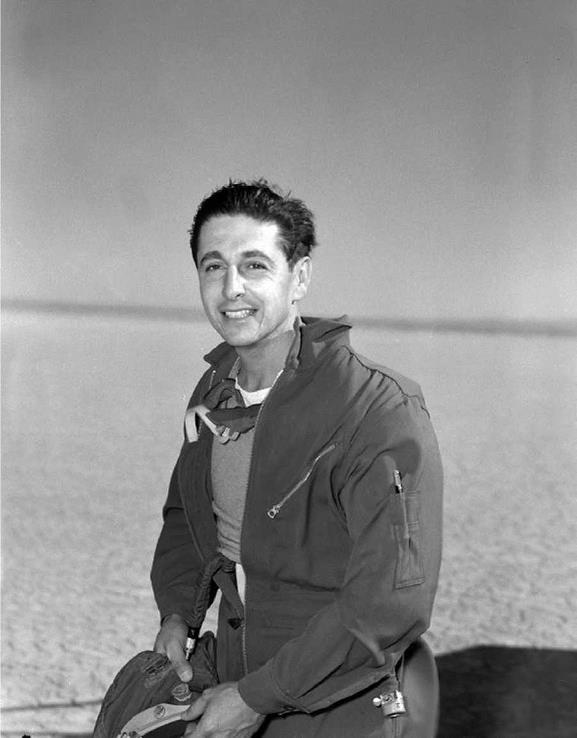

A. Scott Crossfield resigned as a NACA test pilot and joined North American Aviation specifically to work on the X-15 project. Although an accomplished test pilot with many rocket-powered flights under his belt, Crossfield was primarily an engineer and wanted to apply what he had learned to the most advanced research airplane of the era. Crossfield led the charge on keeping the escape system simple and the airplane reliable, and later proved his mettle by flying the X – 15’s first flights. (NASA)

Essential members of the North American team included assistant project engineers Roland L. "Bud" Benner, George Owl, and Raun Robinson. Others included powerplant engineer Robert E. Field, regulators and relief-valve expert John W. Gibb, chief of aerodynamics Lawrence P. Greene, project aerodynamicist Edwin W. "Bill" Johnston, and test pilot Alvin S. White. Storms remembers

that "Al White went through all the required training to be the backup pilot to Crossfield and trained for several years—and was not even allowed one flight; that’s dedication!" In addition, L. Robert Carman, who (along with Hubert Drake) developed one of the earliest NACA ideas for a hypersonic airplane, had left the NACA and joined North American to work on the X-15.-6

Years later Storms remembered his first verbal instructions from Hartley Soule: "You have a little airplane and a big engine with a large thrust margin. We want to go to 250,000 feet altitude and Mach 6. We want to study aerodynamic heating. We do not want to worry about aerodynamic stability and control, or the airplane breaking up. So, if you make any errors, make them on the strong side. You should have enough thrust to do the job." Added Storms, "And so we did."-7

Soon after the contract was awarded, Storms and Soule began to know each other much better as North American and NACA began to interact in technical and management meetings. Storms insisted that the contractor team members stay in their own area of responsibility and not attempt to run each other’s areas. Soule agreed with the approach and directed the NACA members similarly. At least initially, Storms and Feltz were somewhat surprised that Soule insisted on frequent meetings between small groups—seldom more than 10 to 12 people. Nevertheless, Storms remembers, "[S]urprisingly, we managed to get much accomplished, and we all left the meetings with a good concept of what had to be accomplished and when." In later years, Storms was appreciative of the work done by Soule, and in 1989 commented that "I can’t say enough about how well, in my opinion, Hartley did his job. He was a very outstanding program manager and has been greatly neglected in recognition."-8

When North American signed the final contract, the X-15 was some three years away from its first flight. Although most of the basic research into the materials and structural science was complete, largely thanks to the researchers at Langley, a great deal of work remained. This included the development of fabrication and assembly techniques for Inconel X and the new hot-structure design. North American and its subcontractors met the challenge of each problem with a practical solution that eventually consumed some 2,000,000 engineering man-hours. These included 4,000 hours logged in 15 different wind tunnels that provided more than 2 million data points.-9

The Air Materiel Command had excluded the Langley study as a requirement in the invitation-to – bid letter circulated to the airframe contractors. Nevertheless, the influence of the Becker study was evident in North American’s winning proposal. The North American vertical stabilizers used the thick-wedge airfoil developed by Charles McClellan, and the dihedral in the horizontal stabilizer had been a feature of the Langley configuration. In addition, North American used Inconel X and a multi-spar wing with corrugated webs.

One major difference between the Becker study and that of North American was that the latter used all-movable horizontal stabilizers, resulting in the elimination of separate elevators and ailerons. The "rolling tail" allowed the horizontal stabilizers to deflect differentially to provide roll control, or together for pitch control. During the proposal evaluation the government considered this a "potential risk," and several evaluators believed that it represented an overly complicated approach. However, the rolling tail allowed North American to eliminate the protuberances covering the aileron actuators in the thin wing, and allowed a generally simpler structure for the entire wing. Although the additional drag of the protuberances was of little concern, they would have created another heating problem.-^

instead of the separate tanks inside a semi-monocoque fuselage envisioned by Langley. The monocoque tanks were lighter and stronger than separate tanks, but challenged the designers to find ways to route plumbing, wiring, and control cables—hence the tunnels.-1111

In mid-October 1955, both Ames and the HSFS sent comments to Hartley Soule expressing concerns about the North American design. Ames wanted to change the structure of the wing leading edge, the fuselage nose, and the ventral stabilizer, as well as to add an augmentation system to help control longitudinal damping. Ames also suggested additional study into the overall shape of the fuselage and the location of the horizontal stabilizer. Further, as they had during the proposal evaluation, researchers at Ames continued to believe that North American had overly simplified the heat transfer analysis. The HSFS recommended changing the design dynamic pressure, the load factors, the wing leading edge, the aerodynamic and ballistic control systems, the propellant system, the landing procedure, and various crew provisions. Engineers at the HSFS took this opportunity, again, to recommend using an interim LR8 engine during the early flight tests.1121

These and other concerns about the North American configuration prompted a meeting at Wright Field on 24-25 October 1955 that was attended by representatives from North American, Reaction Motors, the Air Force, and the NACA. The Navy did not attend. Subsequent meetings at the North American Inglewood plant took place on 27-28 October and 14-15 November; again, the Navy was not in attendance. Major discussion items included the fuselage tunnels and rolling tail. NACA researchers worried that vortices created by the side tunnels might interfere with the vertical stabilizer, and suggested making the tunnels as short as possible. North American agreed to investigate the tunnels’ effects during an early wind-tunnel model-testing program. The company also assured the government that the rolling tail had proven effective in wind-tunnel testing and appeared to offer significant benefits with few, if any, drawbacks.1131

In early November, Bill Johnston and members of the North American aerodynamic staff met with John Becker, Arthur Vogeley, and Hartley Soule to discuss NACA wind-tunnel support for the X – 15. North American proposed acquiring data at Mach numbers between 0.7 and 3.5 with a 1/10- scale model in the Ames Unitary Tunnel. High-speed information, obtained between Mach numbers 3.0 and 6.3, would come from a 1/50-scale model in the Ames 10 by 14-inch hypersonic tunnel. The use of Ames was logical because it was nearer to the North American facilities than Langley, and in the days of travel by car or piston-powered airliners, distance counted. John Becker and his staff believed that more tests were required, and proposed two different programs depending upon which facilities were available:1141

|

Plan A: |

Mach Number |

Laboratory |

Facility |

Scale |

|

0.6-1.4 |

Langley |

8-foot transonic tunnel |

1/15 |

|

|

1.4-5.0 |

Langley |

4×4-foot unitary complex |

1/15 |

|

|

3.0-6.3 |

Ames |

10×14-inch hypersonic tunnel |

1/50 |

|

|

6.9 |

Langley |

11-inch hypersonic tunnel |

1/50 |

|

Plan B: |

0.6-1.4 |

Langley |

8-foot transonic tunnel |

1/15 |

|

1.6, 1.8, 2.0, 2.2 |

Langley |

4×4-foot supersonic pressure tunnel |

1/15 |

|

|

2.5, 3.0, 3.5, 4.0 |

Langley |

Mach 4 jet facility |

1/50 |

|

|

3.0-6.3 |

Langley |

10×14-inch hypersonic tunnel |

1/50 |

|

|

6.9 |

Langley |

11-inch hypersonic tunnel |

1/50 |

Not surprisingly, these tests were concentrated in Langley facilities. The meeting also covered dynamic stability tests, but researchers agreed that the desirability of such tests would be determined after information from Mach 5 flights at the PARD was evaluated. Two models would be tested—one based on the original Langley configuration, and the other based on the North American configuration. North American wanted to obtain the 1/50-scale results quickly to incorporate them into the 1/15-scale model used to test speed brake and control surface hinge moments.-151

The new rocket engine also came under scrutiny. Meetings held during early November among the HSFS, Lewis, and Reaction Motors included discussions about converting the XLR30 from anhydrous ammonia to a hydrocarbon fuel (JP-4 or kerosene). An earlier analysis had allowed Lewis to determine that the thrust and specific impulse would be almost identical between the two fuels. Lewis pointed out that pressure gages containing copper consistently failed within six months when used in a test cell with anhydrous ammonia, even though the gages were never in direct contact with the fuel. Researchers suggested converting the XLR30 to JP-4 to eliminate the perceived toxicity, corrosion, and handling problems entailed by the use of ammonia. Lewis also recommended that North American actively participate in the engine development program to ensure airframe compatibility. The researchers further suggested that a large number of engine parameters in the aircraft and on the ground should be recorded during each flight, and the engine should not be throttled below 50%.[16]

At the same time, John Sloop at Lewis wrote to Hartley Soule seconding the HSFS’s recommendation to use the LR8 as an interim engine for the initial flight tests. It was already evident that the airframe would be ready long before the engine. For its part, Reaction Motors believed that using the LR8 made a great deal of sense since the early flights would need little power, and it might be difficult to throttle the larger engine to such low levels.-1171

On an almost humorous note, it appears that when the issuing agency wrote the contracts for North American and Reaction Motors, it did not understand that North American had proposed to use integral propellant tanks for their X-15 design. The contracts stated that the engine manufacturer would supply the entire propulsion system, including the necessary propellant tanks. This resulted in some initial concerns over what parts of the propulsion system would be provided by which contractor. It obviously made no sense for Reaction Motors to provide major structural pieces of the airframe. A meeting on 7 November resulted in North American agreeing to furnish all of the tanks for the propulsion system, while Reaction Motors would supply all of the necessary valves and regulators. At the same meeting, everybody agreed that Reaction Motors would supply 12 engines for the program, subject to a contract modification from the Air Force to provide funds. Of these, two would be used for testing (one a spare), and one equivalent engine would be used as component spares, leaving nine engines for the flight program. As it turned out, the government later purchased a few more.-18