HYPERSONICS

Hypersonic. Adj. (1937). Of or relating to velocities in excess of five times the speed of sound.-132

Between the two world wars, hypersonics was an area of great theoretical interest to a small group of aeronautical researchers, but little progress was made toward defining the possible problems, and even less in solving them. The major constraint was power. Engines, even the rudimentary rockets then available, were incapable of propelling any significant object to hypersonic velocities. Wind tunnels also lacked the power to generate such speeds. Computer power to simulate the environment had not even been imagined. For the time being, hypersonics was something to be contemplated, and little else.

By the mid-1940s it was becoming apparent to aerodynamic researchers in the United States that it might finally be possible to build a flight vehicle capable of achieving hypersonic speeds. It seemed that the large rocket engines developed in Germany during World War II might allow engineers to initiate development with some hope of success. Indeed, the Germans had already briefly toyed with a potentially hypersonic aerodynamic vehicle, the winged A-4b version of the

V-2 rocket. The only "successful" A-4b flight had managed just over Mach 4 (about 2,700 mph) before apparently disintegrating in flight.[33] Perhaps unsurprisingly, in the immediate post-war period most researchers believed that hypersonic flight was a domain for unmanned missiles.134

When the U. S. Navy BuAer provided an English translation of a technical paper by German scientists Eugen Sanger and Irene Bredt in 1946, this preconception began to change. Expanding upon ideas conceived as early as 1928, Sanger and Bredt concluded in 1944 that they could build a rocket-powered hypersonic aircraft with only minor advances in technology. This concept of manned aircraft flying at hypersonic velocities greatly interested researchers at the NACA. Nevertheless, although there were numerous paper studies exploring variations of the Sanger – Bredt proposal during the late 1940s, none bore fruit and no hardware construction was undertaken.1351

One researcher who was interested in exploring the new science of hypersonics was John V.

Becker, the assistant chief of the Compressibility Research Division at the NACA Langley Aeronautical Laboratory in Hampton, Virginia.-1361 On 3 August 1945, Becker proposed the construction of a "new type supersonic wind tunnel for Mach number 7." Already a few small supersonic tunnels in the United States could achieve short test runs at Mach 4, but the large supersonic tunnels under construction at Langley and Ames had been designed for Mach numbers no higher than 2. Information captured by the Army from the German missile research facility at Peenemunde had convinced Becker that the next generation of missiles and projectiles would require testing at much higher Mach numbers.-1371

As the basis for his proposed design, Becker extrapolated from what he already knew about supersonic tunnels. He quickly discovered that the compressible-flow theory for nozzles dictated a 100-fold expansion in area between Mach 1 and Mach 7. Using normal shock theory to estimate pressure ratio and compressor requirements, Becker found that at Mach 7 the compressor system would have to grow to impractical proportions.1381

Hope for alleviating the compressor problem had first appeared in the spring of 1945 when Becker gained a fresh understanding of supersonic diffusers from a paper by Arthur Kantrowitz and Coleman duPont Donaldson.1391 The paper focused on low-Mach-number supersonic flows and did not consider variable geometry solutions, but it was still possible to infer that changing the wall contours to form a second throat might substantially reduce the shock losses in the diffuser. Unfortunately, it appeared that this could only be accomplished after the flow had been started, introducing considerable mechanical complexity. The potential benefits from a variable – geometry configuration were inconsequential at Mach 2, but Becker determined that they could be quite large at Mach 7. In the tunnel envisioned by Becker, the peak pressure ratios needed to start the flow lasted only a few seconds and were obtained by discharging a 50-atmosphere pressure tank into a vacuum tank. Deploying the second throat reduced the pressure ratio and power requirements, allowing the phasing-in of a continuously running compressor to provide longer test times. It was a novel concept, but a number of uncertainties caused Becker to advise the construction of a small pilot tunnel with an 11 by 11-inch test section to determine experimentally how well the scheme worked in practice.1401

|

|

John V. Becker was the lead of the NACA Langley team that accomplished much of the preliminary work needed to get a hypersonic research airplane approved through the NACA Executive Committee and Department of Defense. Becker continued to play an import role with the X-15 throughout the development and flight programs. (NASA)

Not everybody agreed that such a facility was necessary. The NACA chairman, Jerome C. Hunsaker,[41] did not see any urgency for the facility, and Arthur Kantrowitz, who designed the first NACA supersonic wind tunnel, did not believe that extrapolating what little was known about supersonic tunnels would allow the development of a hypersonic facility. The most obvious consequence of the rapid expansion of the air necessary for Mach 7 operation was the large drop in air temperature below the nominal liquefaction value. At the time, there was no consensus on the question of air liquefaction, although some preliminary investigations of the condensation of water vapor suggested that the transit time through a hypersonic nozzle and test section might be too brief for liquefaction to take place. Nevertheless, Kantrowitz, the head of Langley’s small gas-dynamics research group, feared that "real-gas effects"—possibly culminating in liquefaction —would probably limit wind tunnels to a maximum useful Mach number of about 4.5.[42

Nevertheless, Becker had his supporters. For instance, Dr. George W. Lewis,[43] the Director of Aeronautical Research for the NACA, advised Becker, "Don’t call it a new wind tunnel. That would complicate and delay funding," so for the next two years it was called "Project 506." The estimated $39,500 cost of the pilot tunnel was rather modest, and given Lewis’s backing, the facility received quick approval.[44]

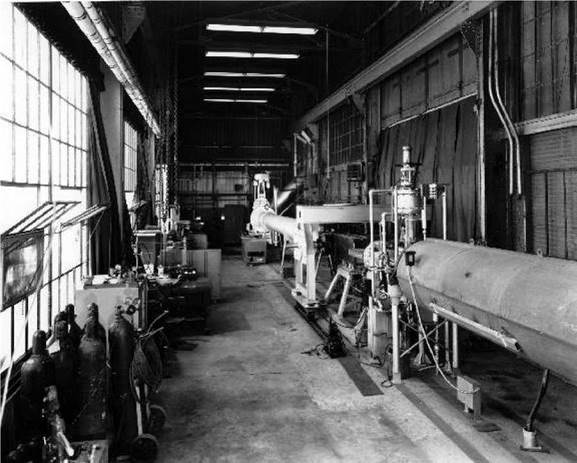

In September 1945 a small staff of engineers under Charles H. McLellan began constructing the facility inside the shop area of the old Propeller Research Tunnel. They soon discovered that Kantrowitz’s predictions had been accurate—the job required more than extrapolation of existing supersonic tunnel theory. The pilot tunnel proposal had not included an air heater, since Becker believed he could add it later if liquefaction became a problem. As work progressed, it became increasingly clear that the ability to control air temperature would greatly improve the quality and scope of the research, and by the end of 1945 Becker had received approval to include an electric

heater. This would maintain air temperatures of about 850°F, allowing Mach 7 temperatures well above the nominal liquefaction point.[45]

The first test of the "11-inch" on 26 November 1947 revealed uniform flow at Mach 6.9, essentially meeting all of the original intents. An especially satisfying result of the test was the performance of the variable-geometry diffuser. McLellan and his group had devised a deployable second throat that favored mechanical simplicity over aerodynamic sophistication, but was still very effective. The benefit appeared as an increased run duration (in this case an increase from 25 seconds to over 90 seconds).[46]

For three years the 11-inch would be the only operational hypersonic tunnel in the United States and, apparently, the world. Several basic flow studies and aerodynamic investigations during this period established the 11-inch as an efficient tool for general hypersonic research, giving Langley a strong base in the new field of hypersonics. Without this development, Langley would not have been able to define and support a meaningful hypersonic research airplane concept in 1954. Throughout the entire X-15 program, the 11-inch would be the principal source of the necessary hypersonic tunnel support.[47]

|

|

The 11-inch at NACA Langley was intended as a pilot tunnel for a larger hypersonic wind tunnel when it opened in 1947. However, it proved so useful that it stayed in service until 1973, and the research documented in it resulted in over 230 publications. Much of the early work on what became the X-15 was accomplished in this wind tunnel. (NASA)

decommissioned, NASA donated the tunnel to the Virginia Polytechnic Institute in Blacksburg, Virginia.1481

As the 11-inch tunnel at Langley was demonstrating that it was possible to conduct hypersonic research, several other facilities were under construction. Alfred J. Eggers, Jr., at the NACA Ames Aeronautical Laboratory at Moffett Field, California,1491 began to design a 10 by 14-inch continuous-flow hypersonic tunnel in 1946, and the resulting facility became operational in 1950. The first hypersonic tunnel at the Naval Ordnance Facility, constructed largely from German material captured from the uncompleted Mach 10 tunnel at Peenemunde, also became operational in 1950.1501

Interestingly, NASA did not authorize a continuously running hypersonic tunnel that incorporated all of the features proposed in the 1945 Becker memo until 1958. Equipped with a 1,450°F heater, the design velocity increased from Becker’s proposed Mach 7 to 12. As it ended up, although the tunnel attained Mach 12 during a few tests, severe cooling problems in the first throat resulted in a Mach 10 limit for most work. The enormous high-pressure air supply and vacuum tankage of the Gas Dynamics Laboratory provided blow-down test durations of 10-15 minutes. Together with improved instrumentation, this virtually eliminated the need to operate the tunnel in the "continuously running" mode, and nearly all of Langley’s "continuous-running" hypersonic tunnel operations have been conducted in the "blow-down" mode rather than with the compressors running.1511