Bolkhovitinov S

Purpose: Ultra-fast attack bomber.

Design Bureau: WIA (air force engineering academy) located at the Zhukovskii Academy, Moscow, where Viktor Fedorovich Bolkhovitinov was Professor of Aircraft Design and head of design team.

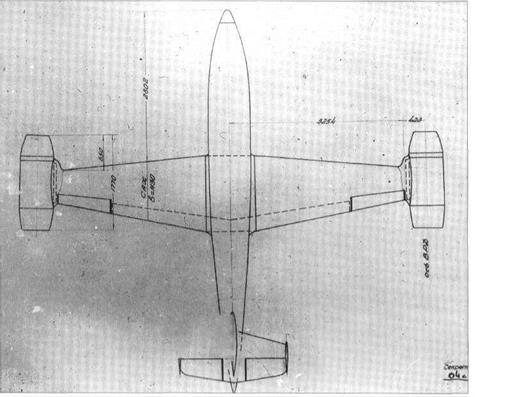

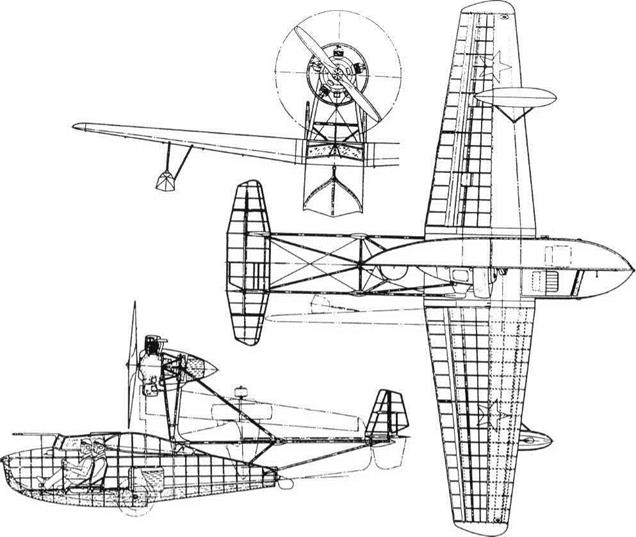

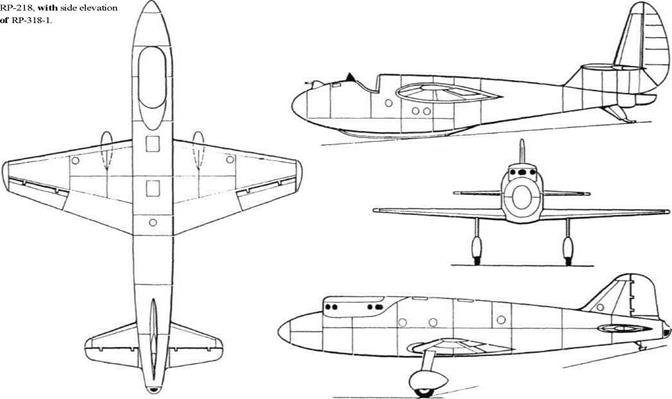

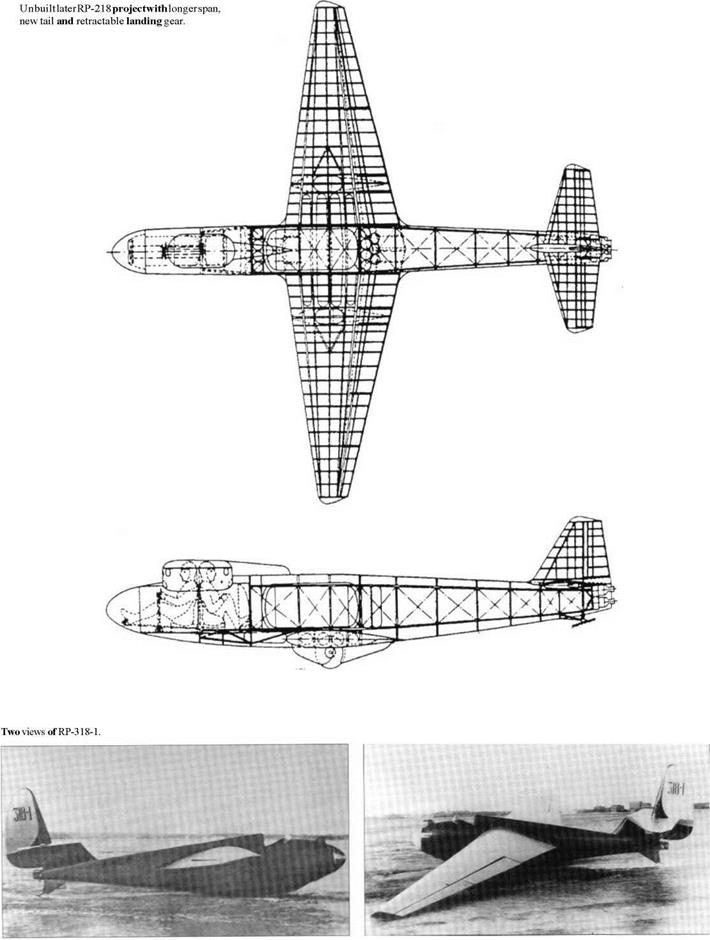

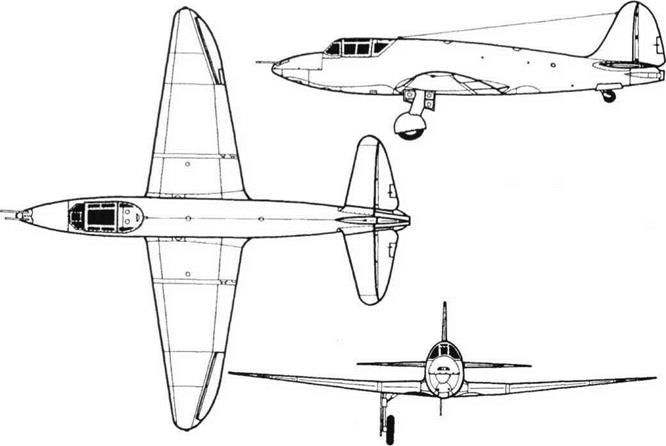

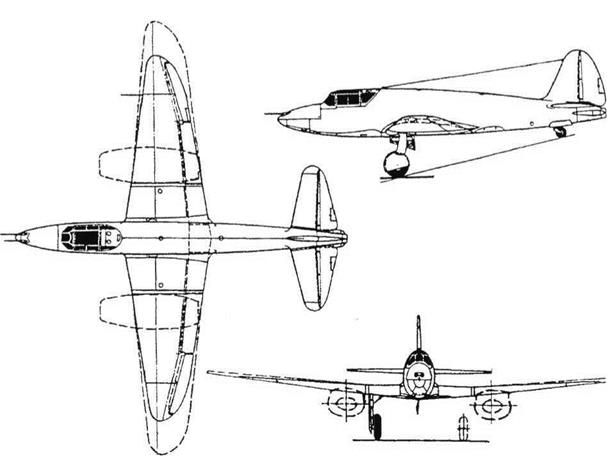

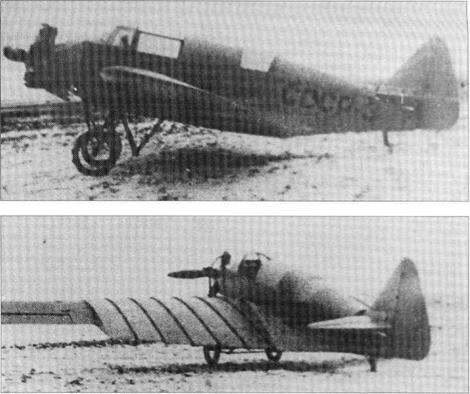

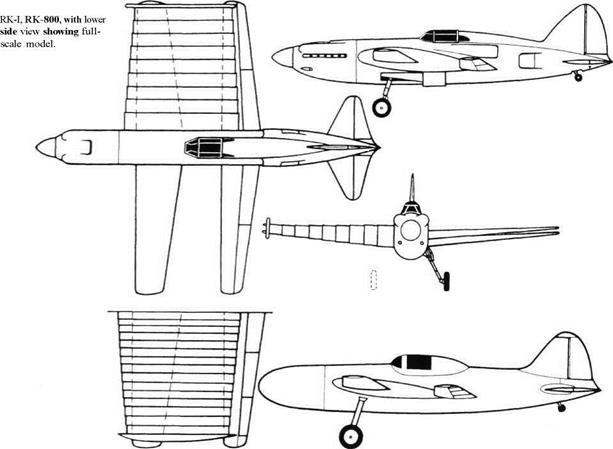

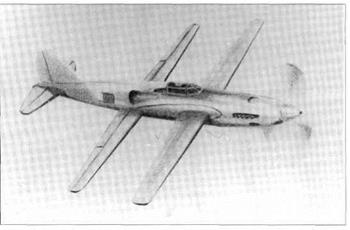

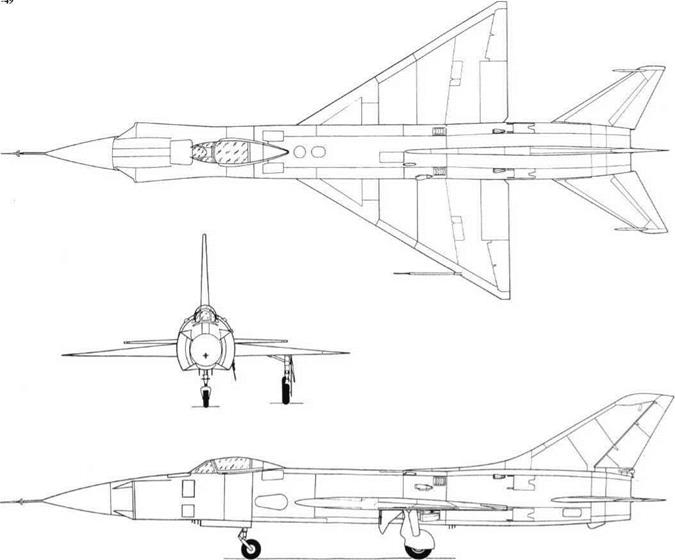

The objective was to make the fastest bomber in the world, by using a fighter-type layout with two powerful engines in tandem. This arrangement was adopted in order to achieve engine-out safety with minimum drag. Design of the propulsion system began in 1936 and of the aircraft itself a year later. The designation stood for Sparka (Twin), but other designations were S 2M-103 (in usual Soviet style, showing the engines), BBS-1 (short-range bomber, fast, the S here meaning Skorostnii, speedy) and LB-S (light bomber, twin). Construction of the single prototype began in July 1938, the first flight was made by B N Kudrin in late 1939, and NIl-WS testing took place between March and July 1940, the pilots being Kudrin and AIKa – banov. It was found that take-off run was excessive. In 1940-41 the aircraft was subjected to major modifications. ZI Itskovich redesigned the wing with increased area and a changed aerofoil profile. A different front en

gine was fitted, and the rear engine and its propeller were replaced by an inert mass. The oil coolers were incorporated in the main radiator duct. As the redesigned aircraft neared completion snow was still on the ground, and the landing gears were all replaced by fixed skis.

No way was found to make proper use of the bay previously occupied by the rear engine, and in any case performance was now unimpressive. After the German invasion work was abandoned. Plans for an improved S bomber and a derived I (or I-1) fighter with two M-107 engines were also dropped.

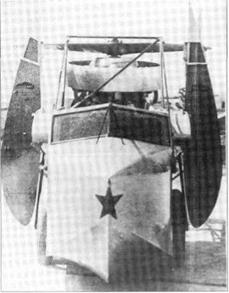

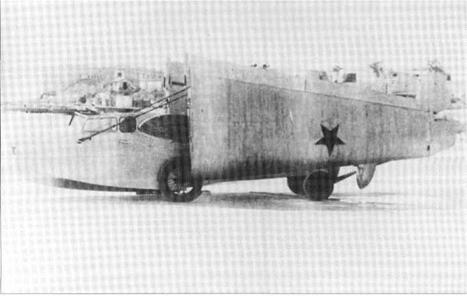

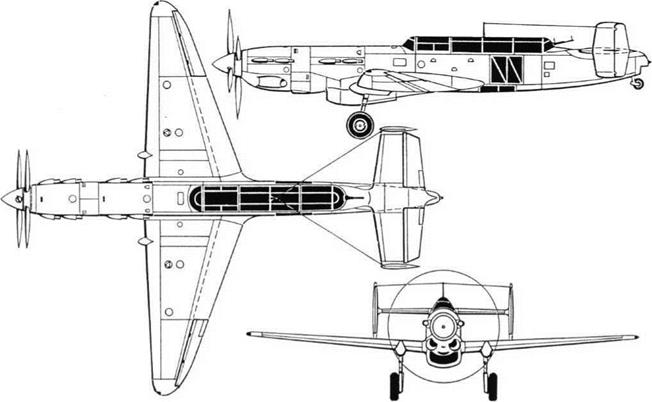

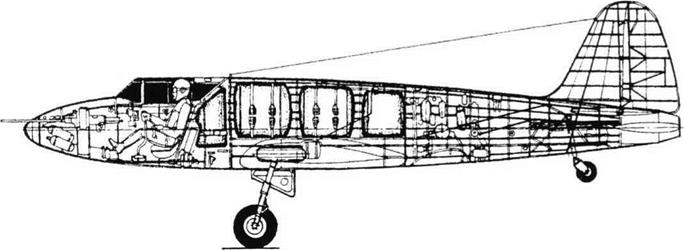

The airframe was entirely a modern light – alloy stressed-skin structure. The wing was based on a structural box with two plate spars with flanged lightening holes, sheet ribs and heavy upper and lower skins with flush riveting. The fuselage basically comprised top, bottom and side panels all joined to four strong angle-section longerons (Shavrov: ‘later this construction was used for the IL-28’, a post-war jet bomber). The twin-finned tail had thin Dl skin throughout, the rudders having inset balanced hinges, the tailplanes being pivoted and driven by irreversible trimming motors and the elevators having trim tabs and a variable geared drive. Each main

landing gear retracted electrically backwards, the wheel turning through 90°.

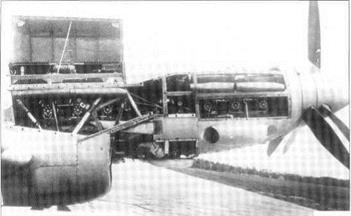

The 960hp M-103 engines (V-12 liquid – cooled derived from the Hispano-Suiza 12Y) were mounted in tandem, the rear engine driving the rear unit of the contra-rotating six – blade propeller. Some reports state that the drive was taken via left/right twin shafts past the front engine’s crankcase, but in fact (as in the Italian Macchi M. C.72 racing seaplane of 1933) the rear engine drove a single shaft between the front-engine cylinder blocks which finally passed through the centre of the front – engine propeller shaft. Both engines were served by a large ducted radiator with a controllable exit flap (this was positioned by one of the 29 on-board electric actuators) and two oil coolers were fitted in ducts on each side of the front engine. Four fuel tanks were housed between the wing spars, and on the trailing edge were electrically driven slotted flaps (in several reports, incorrectly called Fowler

type).

Pilot and navigator sat in tandem, far apart under a long Plexiglas canopy. The navigator also had a bomb sight, and the entire area around his seat was skinned in Plexiglas. Turning to the rear he could fire a 7.62mm ShKAS, and it was the intention later to re-

place this by twin 12.7mm UBT. Behind the rear spar, under the pilot’s cockpit, was a bay housing 400kg (882 Ib) of bombs, with two electrically driven doors. It was the intention later to fit fixed guns in the wings.

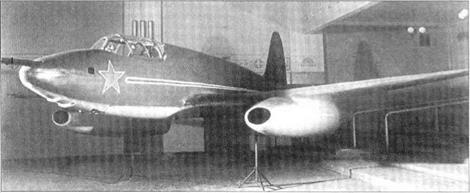

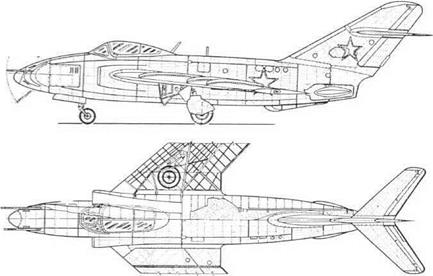

The second wing, of NACA-230 profile, gave improved field length. One report states that a remotely controlled ShKAS was added in the extreme tail, but this does not appear in any known photographs. Continued potentially dangerous problems with the rear engine and its drive resulted in this being removed. The front engine was changed to an M-l 05P, ofunchanged 960hp, driving a single three-blade propeller. Even with weight considerably reduced the S was then judged a failure, though tandem-engine studies continued. The factory was tooled up for Pe-2 production.

Though an article by Ing V Mikhailov and Ing VPerov states that, following initial Nil testing ‘the design team was instructed to continue development’, there is no doubt the S was always on the verge of success but never getting there. The high wing loading and the failure to solve the rear-engine drive problem made it one of the programmes abandoned after the invasion of June 1941.

|

Dimensions |

||

|

Span (original) |

11.38m |

37 ft 4 in |

|

(new wing) |

12.2m |

40 ft X in |

|

Length (original) |

13.2m |

43 ft 4 in |

|

(one engine) |

13.0m |

42ft73/iin |

|

Wing area (original) |

22.9 m2 |

246.5ft2 |

|

(new wing) |

23.43m2 |

252.2 ft2 |

|

|

|

|

|

|

|

||

302P

302P

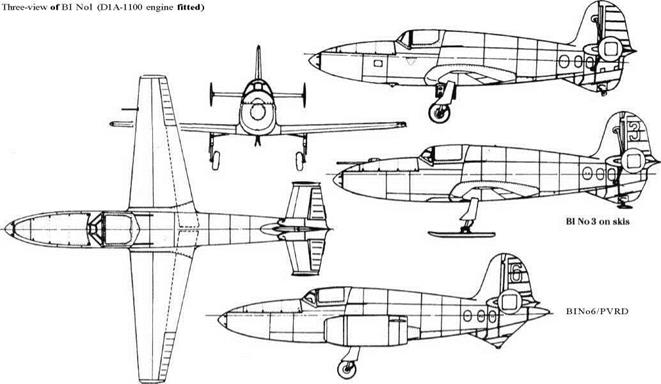

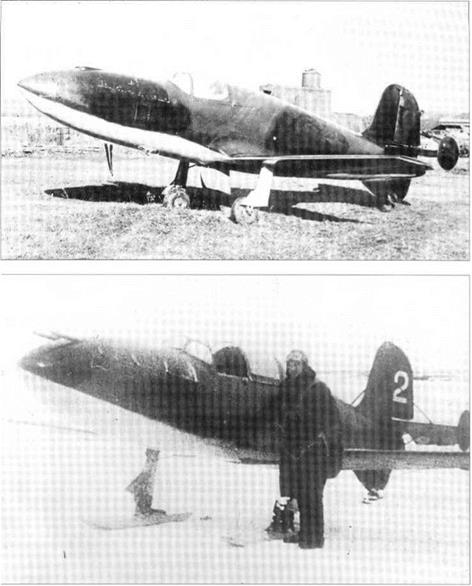

This terminated the delayed plan to build a production series of 50 slightly improved aircraft, but testing of the prototypes continued. Until the end of the War these tested various later Dushkin engines, some with large thrust chambers for take-off and combat and small chambers to prolong the very short cruise endurance (which was the factor resulting in progressive waning of interest). Other testing attempted to perfect a sealed pressurized cockpit. To extend duration significantly BI No 6 was fitted with a Merkulov DM-4 ramjet on each wingtip. These were fired during test in the CAHI T-101 wind tunnel, but not in flight.

This terminated the delayed plan to build a production series of 50 slightly improved aircraft, but testing of the prototypes continued. Until the end of the War these tested various later Dushkin engines, some with large thrust chambers for take-off and combat and small chambers to prolong the very short cruise endurance (which was the factor resulting in progressive waning of interest). Other testing attempted to perfect a sealed pressurized cockpit. To extend duration significantly BI No 6 was fitted with a Merkulov DM-4 ramjet on each wingtip. These were fired during test in the CAHI T-101 wind tunnel, but not in flight.