The He 176 was by no means the end of rocket plane development in Nazi Germany. Alexander Lippisch, the brilliant aerodynamicist who had designed the Ente sailplane which formed the basis of von Opel’s first rocket plane, had in the late 1930s been working on the design for the DFS 194. This was to be a delta-wing airplane without horizontal tail stabilizers, driven by a pusher propeller (at the rear rather than in the nose). The lack of a tail on an airplane not only decreases aerodynamic drag but also results in greater effective lift: a normal wing has the tendency to push the nose of a plane downward, which in conventional planes is compensated by the horizontal stabilizers in the tail. But for them to push the nose up they must push the tail down, which requires negative lift. The result is a balanced airplane but the negative lift of the tail must be made up by additional positive lift from the wings. A well-designed tailless airplane does not need such negative-lift stabilizers. The delta shape of the DFS 194 meant that the wing ailerons could be placed close enough to the rear of the plane to give sufficient leverage for pitch control when both were moved in the same direction, thus eliminating the need for separate horizontal stabilizers with elevators. When moving in opposite directions they would still be able to roll the plane. Due to their dual aileron and elevator functions these control surfaces are called elevons.

Although the DFS 194 is being developed at the Deutsche Forschungsanstalt fur Segelflug (DFS; the German Institute for Sailplane Flight), the RLM considers it to be a good basis for a rocket propelled fighter plane. The work begins at the DFS in cooperation with Heinkel but apart from valuable tests using models in a wind tunnel and in the open air, progress is too slow for Lippisch’s liking. When in late

1938 he is told that his group is to be disbanded because the DFS believes there is no need for a tailless military rocket plane, Lippisch and many of his staff decide to leave the DFS. After negotiations with both Heinkel and Messerschmitt, in January

1939 the project is transferred to the Messerschmitt factory in Augsburg. The decision to join Heinkel’s main competitor may have reflected the fact that Willy Messerschmitt was a more diplomatic salesman than Ernst Heinkel and he had good ties with Hermann Goring.

At Messerschmitt the prototype DFS 194, which the DFS permits Lippisch to take with him, is further developed as ‘Project X’. Late in 1939 the completed airframe is sent to Peenemunde West to be mated with its Walter RI-203 engine. This is similar to the one used earlier in the He 176 but has the advantage that its thrust can be adjusted by the pilot, whereas the previous engine had a fixed thrust. The first gliding flight is made in July 1939 piloted by Heini Dittmar, and by October the aircraft is undergoing engine ground tests. The successful engine tests are followed by the first powered flight in August 1940, when Dittmar flies the DFS 194 to a top speed of 550 km per hour (340 miles per hour). As he later recalled: “With nearly 1,500 pounds of thrust, and as I pulled up steeper and steeper without losing one knot of airspeed, I knew that we were beginning a new era in flight.” Combining a graceful glider with the raw power of a rocket engine results in excellent flying characteristics, and the DFS 194 proves to be a good basis for an operational rocket fighter.

|

The first powered flight of the DSF 194.

|

The RLM consents to the production of a series of five prototypes of an improved design, which is named the Messerschmitt Me 163A. The project name ‘Me 163’ had earlier applied to the development of a short-take-off, slow-speed aircraft; it is hoped that using the same name will deflect unwanted attention from the new, secret rocket plane project. In line with this subterfuge, the first prototype is named the Me 163A V4 to suggest a follow up to the three prototypes planned for the slow-speed plane. The Me 163A uses the Walter RII-203 motor in which ‘T – Stoff composed of 80% hydrogen peroxide with some stabilizing additives is decomposed by a liquid sodium or calcium permanganate solution catalyst called ‘Z-Stoff. It produces a maximum thrust of 7,400 Newton. The propellants are injected into the combustion chamber by pumps which run on T-Stoff sprayed over a cement-like solid Z-Stoff ‘stone’. For stability of the aircraft, the bulk of the engine mass must be placed near the center of the airplane, close to the center of gravity of the airframe and the place where the lift from the wings is concentrated. The combustion chamber with the nozzle is placed in the tail, linked to the rest of the engine by a long thrust tube. The vivid violet color of the permanganate causes the Me 163A to leave a huge purple exhaust trail in flight.

The Y4 prototype makes its first towed flight at Augsburg on 13 February 1941 under the control of Dittmar, but the first powered flight does not occur until August due to delays in the development of the Walter engine. When the plane finally flies under rocket power the results are spectacular: once airborne, Dittmar sets off on a horizontal trajectory close to the ground in order to gain speed, then pulls up the nose and makes an incredibly steep ascent: from the moment it leaves the runway the Me 163A needs only 55 seconds to climb to an altitude of 4.0 km (13,000 feet)! It also proves to have excellent flying characteristics. On 2 October Dittmar sets the incredible new world speed record of 1,003 km per hour (623 miles per hour) in level flight, making the Me 163A V4 prototype much faster than anything else in the sky at that time. For the occasion it was towed to an altitude of 4.1 km (13,500 feet) in order to maximize the amount of propellant available for the record attempt. Because of the project’s top secret status, the flight was not officially recorded internationally and was disclosed only after the war. (It would not be surpassed until August 1947, well after the war, when the experimental Douglas D-558-1 Skystreak turbojet aircraft in the US flew slightly faster.)

However, the record flight of the Y4 reveals that such high transonic velocities are pushing the Umits of its aerodynamic design, because at its maximum speed the plane suddenly pitches nose down. Dittmar is subjected to a negative acceleration of 11 G (acceleration results in positive G, what pilots call ‘eyeballs in’; negative G is deceleration, or ‘eyeballs out’) but he quickly manages to throttle back. The plane

|

Me 163A prototype number V4 [Bundesarchiv].

|

slows down and becomes controllable again. As the aircraft approached Mach 1, he had encountered a phenomenon called ‘Mach tuck’, which is a disruption of the air flow over the wing that causes a plane to nose over (as will be described in more detail later). The outer limit of the speed envelope of the Me 163 had been found.

The five Me 163A prototypes are followed by eight pre-production examples that are designated Me 163A-0, then by an improved and significantly larger operational combat version called the Me 163B. It is officially named the ‘Komet’ (Comet), but the pilots name it ‘Kraftei’ (Power Egg). The main advantage of the ‘B’ is its much more powerful engine. The He 176, DFS 194 and Me 163A all had engines in which hydrogen peroxide was decomposed to produce a reasonable thrust at relatively low temperatures; the Me 163A engine exhaust temperature was about 600 degrees Celsius (1,100 degrees Fahrenheit). These types are often referred to as the ‘cold’ Walter engines. In contrast, the Me 163B is powered by a ‘hot’ Walter HWK 109- 509A (initially the 509A1 but later the improved A2 version) rocket that burns concentrated ‘T-Stoff (hydrogen peroxide) and ‘C-Stoff consisting of 57% methyl alcohol (made from potatoes), 30% hydrazine hydrate and 13% water. The T-Stoff decomposes under the influence of a dissolved copper salt catalyst mixed in with the C-Stoff, while the hydrate helps the alcohol fuel to ignite spontaneously with the hot oxygen produced by the T-Stoff decomposition. The exhaust temperature of the ‘hot’ engine is 1,800 degrees Celsius (3,300 degrees Fahrenheit). The new engine gives the Me 163B more than double the thrust of the Me 163A. It also produces less smoke, making it harder for enemy planes to spot the Komet.

The 16,000 Newton that the new 509A1 engine provides (17,000 Newton for the later 509A2) is high in comparison to the force of gravity on the plane when it is nearly empty (with a weight of 1,900 kg, or 4,200 pounds, corresponding to about 19,000 Newton) and therefore towards the end of its powered run the Me 163B can climb almost straight up. The maximum speed of the operational, armed fighter plane is 960 km per hour (600 miles per hour), which corresponds to Mach 0.91 at 12 km (40,000 feet) altitude; sufficient to enable it to “fly circles around any other fighter of its time”, according to Me 163B chief test pilot Rudolf Opitz.

The thrust of the Me 163B’s engine can be throttled in four stages (idle and then levels 1 to 3) by varying the number of propellant lines that are opened into the combustion chamber. The Walter engine is simple to build, simple to maintain and readily accessible because the entire tail section of the plane can be removed. And rapid replacement is possible because the engine is mounted to the thrust frame within the fuselage using only a few connections.

Two 163B prototypes are built for flight tests. In addition, a number of unpowered 163S glider trainers are built which have an additional instructor cockpit behind and above the usual cockpit. The first tow-glide with the engineless 163B airframe occurs on 26 June 1942 but there is then a long wait for the new engine to become available. The first powered flight is not until 24 June 1943. In part because of this the Komet is unable to enter squadron service until 1944, by which time large fleets of bombers are swarming over Germany and its revolutionary capabilities are desperately needed to stem the tide. Thirty Me 163B-0 are produced armed with two

20-mm Mauser MG 151/20 cannon and about 400 Me 163B-ls with two even more destructive 30-mm Rheinmetall Borsig MK 108 cannon.

The bat-shaped Me 163B is a remarkably small aircraft, with a wingspan of only 9.3 meters (31 feet), a length of 5.8 meters (19 feet) and a maximum take-off weight of 4,300 kg (9,500 pounds) of which about half is propellant. To save battery weight it has a little windmilling propeller on its nose that will turn in the air during flight and drive an electricity generator in order to power the onboard radio. In spite of the emphasis on weight minimization, the pilot is protected by armor plating behind him, a thick section of armored glass immediately above the instrument panel, and an armored nose cone (it was expected that the biggest risk for a Komet pilot was being hit by defensive fire from the bombers it attacked, rather than from an Allied fighter getting on his tail). Due to the lack of metals in Germany late in the war, parts of the wings, which blend beautifully with the fuselage, are made of wood. The short nose and the single-piece blown canopy, which blends aerodynamically with the aft fuselage, gives the pilot good visibility forwards, but he cannot really see what is at his six o’clock (straight behind him); on the other hand, nothing is able to chase him.

The plane takes off at a speed of about 280 km per hour (170 miles per hour) with a much longer run than the distance conventional fighters require. It remains just above the ground until it has achieved the optimal climbing speed of around 680 km per hour (420 miles per hour), whereupon it pulls up into a 70 degree climb and within 3 minutes reaches the bombers at 7 to 10 km (23,000 to 33,000 feet). Movies of its take-off show an amazingly abrupt change from level flight into a steep climb that appears spectacular even today. To spectators used to the gradual

|

і Generator Drive Propeller

|

12 Radio Panel

|

23 intake lor Generator Ventilation

|

34 Distribution Fuse Box

|

|

2 Generator

|

i3 Warning мот tor Cnucai M*cn

|

24 Filter tor Receiver

|

35 Emergency Drainpipe

|

|

3 Transformer for Transmitter

|

14 Oxygen Bottles

|

25 Voltage Regulator

|

38 Drainpipe lor C StO’t

|

|

4 Rudder Pedals

|

15 Anlenna

|

26 Battery Bo*

|

3? Acceleration Tank

|

|

5 Rao>o Transmitter 16 ZE

|

16. Filler Pipe tor T-Stofi

|

27 Tow-ca’ Attachment Point

|

30 Fuel Control and Distribution Box

|

|

6 Vacuum Bott>* lor Variometer

|

17. Ammunition feed Belt

|

28 T-Stofi Cockpit Tank

|

39 Tail Wheel

|

|

7 Instrument Panel

|

18 T-StQH Tank

|

29 Hydraulic Cylinder lor Skid Operation

|

|

|

8 Armored Glass. 90 mm

|

19 T Stoll Starter Tank

|

30 Skid

|

Armament

|

|

9 Rellector Gunsight 16 В

|

20 F. iierCao’or C-StoH

|

31 IFF Receiver 25 a

|

2 Machine Guns in Wing Root (up to V 45)

|

|

IQ Control Column

|

21 Sensing Antenna

|

32 Pilot’s Seat

|

2 Machine Cannons in Wing Root (V 46-V 7Q)

|

|

11. Trim Control

|

22 Anienna Matching unit

|

33. Gun Charger

|

|

Me 163В cutaway diagram.

Me 163В taking off.

climb of propeller fighter aircraft of that time, it must have been awe-inspiring. Also apparent in these movies is the large amount of smoke that escapes from the belly of the Me 163B: this is hot steam from a gas generator in which a small amount of T-Stoff is decomposed (according to the ‘cold’ principle) to drive the turbine which powers the pumps that feed T-Stoff and C-Stoff to the rocket’s

combustion chamber. (This same turbopump system was used by the ‘cold’ engine of the Me 163A.)

Famous German female test pilot Hanna Reitsch was mightily impressed by its power. In her memoirs (published in EngUsh with the title The Sky My Kingdom) she describes operating the plane during an engine check: “To sit in the machine when it was anchored to the ground and be surrounded suddenly with that hellish, flame – spewing din, was an experience unreal enough. Through the window of the cabin, I could see the ground crew start back with wide-open mouths and hands over their ears, while, for my part, it was all I could do to hold on as the machine rocked under a ceaseless succession of explosions. I felt as if I were in the grip of some savage power ascended from the Nether Pit. It seemed incredible that Man could control it.” The mechanics near the plane had to keep their mouths open because otherwise the pressure differences caused by the rocket engine would rupture their eardrums.

Germany managed to equip only one operational fighter wing, Jagdgeschwader (JG) 400, with the Me 163 before the war was over. The first operational Komet mission was flown by commander Major Wolfgang Spate on 14 May 1944. For the occasion the ground crew painted his entire plane bright red, just like ‘Red Baron’ von Richthofen’s famous aircraft of the previous war. It shows the high expectations for the Me 163 as an invulnerable wonder machine capable of outclassing all other aircraft in the sky. But Spate did not appreciate being made such a distinctive target and he had the color removed after the flight. In any case, the paint added 18 kg (40 pounds) of unwanted weight. Nevertheless, the red Komet has become a classic and many illustrations and scale models show the aircraft in this fiery livery. The planes also often had funny squadron artwork on their nose, including a depiction of Baron von Miinchhausen flying through the air on a cannonball, or a drawing of a rocket propelled flea with the text “Wie ein Floh, aber oho!” (like a flea, but wow!)

The operational history of the different squadrons that belonged to JG 400 and the numbers of losses and successes is unclear, with different sources reporting different numbers since the claims of both Komet and Allied pilots about who shot down how many of whom are not always consistent. Komets often attacked bomber formations together with conventional Luftwaffe fighters and in the chaos of air battles mistakes were easily made about which planes were shot down by Komets and which by other aircraft. AlUed bomber crews sometimes reported being under attack by Komets at times and places where none were flying. It appears that JG 400 Komets drew first blood on 16 August 1944, when they damaged several B-17 bombers and killed two American gunners. However, a gunner on another bomber managed to shoot down a Komet and a P-51 Mustang fighter claimed another. The pilot of the first Komet was able to bail out but the other pilot did not. Allied bomber formations were attacked intermittently up until May 1945, resulting in seven American B-17s and one British Lancaster being shot down. But several Komets were lost due to defending fighters and bomber gunners. In addition to attacking bombers, the Me 163B was also used to intercept the high altitude, fast reconnaissance planes that were usually hard to catch. By the time these were spotted it was normally too late to get conventional fighters airborne and up to the right altitude, but the extremely high climb rate of the Komet gave it a better chance of intercepting them. One Mosquito reconnaissance aircraft was indeed intercepted and shot down in November 1944. In March 1945 a Spitfire Mk XI photo reconnaissance plane was attacked by a pair of Me 163Bs but managed to escape by rapidly diving from 10.7 to 5.5 km (6.7 to 3.4 miles), and in the process reached a speed of about 800 km per hour (500 miles per hour). Later that month two Komets intercepted a Mosquito P. R. Mk XVI photo-reconnaissance aircraft near Leipzig. Nicknamed the ‘Wooden Wonder’ because it was mostly made of plywood, the Mosquito was an especially fast and rather agile two-engine plane, but it was not able to outrun an Me 163B. Although the Komet’s cannon shot out the Mosquito’s starboard engine, Canadian Pilot Officer Raymond Hayes managed to escape by very skillful maneuvering. Hayes and his navigator set for home in the crippled plane, but on the way were attacked by another fighter (not a Komet). Hayes managed to evade this second attacker but his aircraft sustained further damage and his navigator was badly injured in the leg. They finally crash-landed in Lille in France. Hayes received the Distinguished Flying Cross for his feat.

By the end of 1944 a total of 91 aircraft had been delivered to JG 400, but due to a severe propellant shortage most never left the ground: the two main factories which produced its special propellant had been demolished in bombing raids in September of that year. Many Komets were destroyed when their bases were bombed. Attacks from the air, and the approach of Allied ground troops, repeatedly obliged the JG 400 pilots to change airfields and this further hampered their operations. When they did manage to find an intact Komet and sufficient propellant, a typical tactic was to shoot upward through a bomber formation in a 70 degree climb, fire a few rounds at the enemy planes, and then turn and dive through the formation at zero thrust while shooting again. Sometimes this could be done twice before running out of propellant. The plane was remarkably agile and docile even at these high velocities, so it could easily both outrun and outmaneuver Allied fighter aircraft. Moreover, it would zoom by so swiftly that the gunners on the slower bombers hardly had time to swing their guns towards the small Komets.

However, the huge difference in airspeed also made hitting the enemy difficult for the Me 163 pilots, even though a bomber was a larger target to aim for and just a few hits from the powerful cannon could cripple even a large multi-engine plane such as a B-17 or a Lancaster. The Komet had to close within a range of about 600 meters (2,000 feet) to have any chance of hitting its target, but had to break off when at 180 meters (590 feet) to avoid a collision. That left less than 3 seconds for shooting the twin MG 151 cannon. Although powerful, these had a rather slow firing rate of 650 rounds per minute. Per attack, the Komet’s two cannon could thus fire only some 65 rounds at a particular bomber. This may sound like a lot, but within that same time a conventional Fw 190D fighter could fire a total of 165 rounds using its four (smaller cahber) cannon. Furthermore, the slower fighter could hold its target for far longer. Another issue was that if the Komet fired its cannon while it was maneuvering, the ammunition belts often jammed. JG 400 First Lieutenant Adolf Niemeyer came up with the idea of installing 24 R4M ‘Orkan’ (Hurricane) missiles under the Komet’s wings. When fired in brief barrages these would be able to knock out a bomber much faster and far more effectively than the twin cannon. Nobody knew how the Me 163 would react to the disturbance of the airflow around its unusually shaped wing while carrying rockets but because the situation for Germany was desperate there was no time for wind tunnel testing and careful analysis. Niemeyer took off in an Me 163A test vehicle with a set of dummy missiles under its wings to find out. Apparently the flight went reasonably well because he survived the experiment (as well as the war). Had Niemeyer been able to mount real rockets on his Komet, he would have become the first man in history to fly a missile-equipped rocket propelled airplane. Such an Me 163B would have been a very lethal weapon indeed, but no Komet ever carried missiles in combat.

One Lancaster bomber did however fall victim to an Me 163B with an experimental SG500 ‘Jagerfaust’ (Hunter’s Fist) weapon system consisting of a set of eight upward-firing, short-barreled guns triggered by a photocell able to detect a bomber’s shadow as the Komet flew underneath it. The system was designed to make it easier for Me 163B pilots to shoot down targets because it did not require careful aiming and timing. The guns were built into the wings, four on each side, and they had to be placed rather far out towards the wingtips and be fired with minute intervals to preclude the explosive shock waves from shattering the canopy. To prevent the recoil from disturbing the aircraft’s flight, the barrel of each gun was ejected downwards as the shell was shot upwards.

Sitting in an Airbus 320 reading about the exploits of the Komet pilots in Stephen Ransom and Hans-Hermann Cammann’s Jagdgeschwader 400, it dawns on me that I am comfortably flying at a speed and altitude at which Me 163B and Allied bombers were slugging it out over northern Europe some 65 years ago. Pilots and crews did not have pressurized cabins, and the engines used were either reliable but slow as in the case of the bomber’s piston engines, or dangerous but fast rocket motors. What at the time were rather extreme flight speeds and altitudes have been standard cruising performance for commercial airliners since the late 1950s: a Boeing 747 typically flies at around 900 km per hour (560 miles per hour) at 11 km (35,000 feet) altitude. The very rapid developments in post-war jet aircraft technology meant that what in 1945 was attainable only by an experimental and extremely dangerous fighter aircraft was perfectly normal for the average tourist-class airhne passenger a mere 15 years later. It is also interesting to note that since then up to the Airbus that I am flying in, airliner operating speeds and altitudes have hardly changed apart from the fantastic Concorde, which is unfortunately no longer in service.

The Me 163B’s performance was revolutionary, but the design was not perfect for operational military use. From the long list of in-flight explosions, engines quitting, weapons jamming, crash landings and aircraft being shot down while gliding back to base, it is clear that the Komet was an experimental aircraft rushed into operational service. On combat missions it was expected that one-third of the aircraft and pilots would not make it back to base. Of those lost, some 80% crashed during take-off or landing, 15% burst into flames or went out of control in flight, and the remaining 5% were shot down. Abysmal numbers for what was supposed to be an operational fighter plane. Another major issue was that the Komet guzzled its propellant at such a rapid rate that it had a total of just 7.5 minutes of powered flight. This meant the fighter could only operate as what we now call a point-defense interceptor, needing

to be stationed close to where the enemy bombers were expected to pass over. A German animation movie of the time shows how the plane would take off when a bomber formation came within a range of 42 km (26 miles), flying towards the Me 163B airbase at an altitude of 7 km (4.4 miles). By the time the bombers had halved that distance, the Komet was in the right position to attack.

Once it ran out of propellant, the Me 163B had to glide back home. AlUed pilots noticed this and tried to attack them during this unpowered descent. This was still a difficult task because even whilst gliding back down the little rocket plane was much more maneuverable than any Allied fighter, and with an unpowered diving speed of over 700 km per hour (440 miles per hour) it was very fast. Shortly before landing, however, the Me 163 was an easy target since it had to fly straight and slow. Allied fighters would circle just outside the defensive perimeter of the airfield’s anti-aircraft guns and from there mount quick attacks on Komets making the final approaches. To counter this tactic, experienced Me 163 pilots would rapidly dive into the protected area at about 800 km per hour (500 miles per hour), then fly circles within the range of the anti-aircraft guns while they bled off excess speed prior to lining up to make a landing approach.

To keep the plane fight, it was not equipped with a proper undercarriage. For take-off it used a jettisonable dolly with two large wheels which, if dropped prematurely, could bounce back against the belly. The plane landed on grass fields using a single extendable skid which was fight and easy to fit into the plane without disrupting its clean aerodynamic shape. It slowed the aircraft down after landing simply by friction with the ground. The skid had hydraulic shock dampeners but these would not work when the skid activation lever in the cockpit was not properly set after deployment. The resulting lack of cushioning in combination with bumpy fields and high landing velocities caused some pilots to suffer back injuries, including experienced test pilot Heini Dittmar when he landed an Me 163A in November 1943. And Hanna Reitsch was badly hurt when the take-off dolly did not separate on her fifth towed training flight in an Me 163B, forcing her to discontinue and land with the wheels attached. Because the dolly made it impossible to deploy the skid and its shock dampener, the plane hit the ground hard, somersaulted and threw her head against the gunsight. She spent several months in hospital and lost her chance to fly the Me 163B under power.

The Me 163B was aerodynamically very clean, and showed its glider heritage by its very flat gliding angle: while unpowered, it would only lose one meter of altitude per 20 meters of distance. Whilst this was great for gliding back to base, it made the plane rather difficult to land: just above the ground the air would become compressed between the wings and the field, forming an air cushion. This ‘ground effect’ could keep the Me 163B floating just above the ground for a long distance, with the merest updraft being sufficient to make it ascend back into the air again. As a consequence, pilots found it difficult to put the Komet down quickly. Since on approach the plane would be unpowered there was no opportunity to circle around for another landing attempt, and a delayed touchdown could easily result in a crash amongst the trees at the periphery of the airfield. And even after touching down the plane needed a run of about 370 meters (1,200 feet) on dry grass to halt, and nearly

|

Deployed landing skid of the Me 163 displayed in the Science Museum in London [Michel van Pelt],

|

twice that on wet grass. With the high landing speed of around 200 km per hour (120 miles per hour) this made landing an Me 163B very challenging. A set of landing flaps, to increase drag while still allowing sufficient lift, provided a modicum of control but it was almost impossible to put an Me 163B down at a precise landing point. Even if the landing were successful, the pilot was still not safe because the Komet had no power to taxi, and was anyway not easy to move on its single skid. It had to be retrieved by a small tractor pulling a trailer equipped with two lifting arms which fitted under the wings, and while waiting out in the open the aircraft was very vulnerable to attack by enemy planes.

Take-off could also be dangerous for an inexperienced pilot because the absence of a propeller-driven airflow over aircraft meant that the aerodynamic controls only became effective at about 130 km per hour (80 miles per hour). Steering during the taxi run was therefore done using the tail wheel, which was coupled to the rudder and so could be operated using the foot pedals. However, it meant that the position of the stick (and thus elevons) was initially immaterial and a pilot might accidentally put it in a turn during the take-off run which could seriously ruin his day when the control surfaces suddenly became functional. A crash soon after an aborted take-off would inevitably lead to a violent explosion of the volatile propellants. The long take-off run of the Komet was also an issue because it required a lot of room and, moreover, used a lot of propellant. A rocket propelled launch rail system was developed to help the plane on its way. This was successfully demonstrated using an Me 163 mockup, but the rails would mean losing the operational flexibility of taking off in any direction from any sufficiently large and reasonably level grassy field.

UnUke modern airplanes, the cockpit of the Me 163 was unpressurized, exposing its pilot to a very quick drop in atmospheric pressure during the fast climb to altitude. Pilots had to eat special low-fiber food to prevent any gas in their gastrointestinal tract from rapidly expanding on the way up. They were also given altitude chamber training to familiarize them with operating in the thin air of the stratosphere without a pressure suit and while breathing through an oxygen mask.

Another major hazard for the Me 163 pilots and their ground crews was that the propellant was very corrosive. The T-Stoff and C-Stoff would explode violently if they came into contact with each other prematurely; even a missed drop could set off a massive explosion of all the propellant in the aircraft. The filling caps on the plane were therefore very clearly marked with a ‘T’ or a ‘C’, and trucks transporting these liquids to the planes were never allowed to get close to one another. After each flight the propellant tanks and rocket engine had to be flushed with water to remove any residual fluids, and the entire aircraft’s surface was washed just to be sure. The pilots wore protective asbestos-mipolam-fiber clothing that would not burn on coming into contact with the concentrated hydrogen peroxide T-Stoff, but the suit was not perfect and if this fluid seeped through a seam it could rapidly react with the pilot’s skin in a chemical reaction that released oxygen, the concentration of which would soon rise to that for spontaneous combustion. In short, the concentrated peroxide would burn a pilot alive, and several pilots were injured by it when propellant lines broke in crash landings. Part of the dangerous liquid was actually put in two small tanks located on each side of the seat in the cramped cockpit, so even a small leak there would have grave consequences for a pilot. The tanks for the T-Stoff had to be kept meticulously clean because even a fingerprint would be enough to cause it to decompose violently into oxygen and hot steam. Because of the dangerous propellant vapors, a pilot had to breathe through his oxygen mask even while the plane was still on the ground, and always had to wear flight goggles to protect his eyes. The Me 163B was not equipped with an ejection seat (the now standard means for escaping from a supersonic or transonic airplane) as this equipment was still very experimental at the time. However, the Me 163B designers did manage to give the pilots some chance of bailing out of a Komet in trouble at 900 km per hour (560 miles per hour): a small drogue chute could be deployed behind the plane to slow it to a velocity at which it was safe to get out of the cockpit, and at which the pilot’s own parachute would not be tom to shreds. But this was not of much use if the engine suddenly exploded upon being ignited for take-off, which frequently happened.

The Komet was the first airplane to really enter the domain of transonic flight near to Mach 1, where the compressibility of the air starts to be noticeable. When a plane flies at the speed of sound, air no longer flows nicely around its nose and over the wings. Wherever the supersonic air hits a significant obstacle, like the blunt nose of an airplane, or a region in which air is flowing at a lower velocity, it is slowed

|

An Me 163 В pilot getting ready for flight.

|

down. But the air molecules are no longer able to move out of the way in order to ensure a smooth flow. Instead they collide with each other and are compressed into a shock wave. While the Me 163 could not reach Mach 1, it still encountered compressibility effects because the airflow over part of its airframe would actually go supersonic. We have seen earlier that air is accelerated when flowing over the wings. This means it locally flows faster than the plane itself is flying through the atmosphere, and thus shock waves can occur even if the plane’s airspeed is just below the speed of sound. The flight Mach number at which the local flow over the wing first goes supersonic is called the ‘critical Mach number’ of the airplane. When flying above the critical Mach number but below the speed of sound, the airplane is in the transonic flight regime.

The thicker the wing, the more the air passing over it will accelerate and thus the lower the critical Mach number of that airplane. Several fast conventional propeller planes of the Second World War experienced air compressibility issues in a fast dive because their wings were relatively thick. The P-38 Lightning had a critical Mach number of 0.68, and thus already started to experience transonic aerodynamic effects when flying at 68% of the speed of sound. Pilots of early versions of the Lightning therefore often ran into trouble when they put the plane into a high speed dive, with the controls suddenly freezing, the tail shaking violently, and the plane nosing into an ever steeper dive beyond the pilot’s control.

When the airflow over the surface of a wing goes supersonic, the point where the sum of the lift forces across the wing’s surface can be thought to originate (called the plane’s center of pressure) moves aft. Basically what happens is that the speed of the airflow over the aft part of the wing is faster (supersonic) than the subsonic flow over the front part of the wing. The aft part thus gives relatively more lift and causes the center of pressure to migrate further aft in the airstream. As a result, the aircraft is no longer balanced along its pitch axis. As the plane enters the transonic regime, the lift force will try to push the nose down.

Another nasty consequence of transonic flight can be a sudden loss of lift. When the airflow over an area of a wing goes supersonic, a shock wave can form at the aft boundary of the supersonic-flow region, beyond which is subsonic flow. This shock wave can grow so strong as to cause the airflow behind it to separate from the wing and no longer nicely follow the wing contours. This leads to a serious loss of lift, a condition called ‘shock stall’. On the P-38 this also meant that the airflow behind the wings went more straight towards the tail and gave the horizontal stabilizer more lift, which only worsened the pitch-down problem. If a P-38 flew faster than its critical Mach number of 0.68 the shift in the center of pressure, in combination with shock stall, would inevitably induce ‘Mach tuck’. The pilot would naturally try to get the nose back up by pulling on the stick, deflecting the tail elevators upward. This would actually give the airflow at the elevator hinge line on the underside of the stabilizer more room, making it expand and hence accelerate. The resulting shock wave near the hinge line would make the elevators shock-stall as well, become ineffective, and cause the plane to uncontrollably nose down into an ever-steepening dive. Since the shock stall happens irregularly and is subject to constant change, the aircraft would also shake violently as it plunged towards the ground. Not surprisingly, a pilot would like to bail out at that point, but without an ejection seat to boost him clear of the airplane this would mean certain death. But if he remained in the plane he actually had a chance of survival because when the diving plane encountered the denser, warmer air at lower altitudes the local atmosphere’s speed of sound would increase. As a result the Mach number would diminish, the shock waves would lose their strength, and the elevators would regain their effectiveness. With luck, the pilot would be able to pull up before creating a hole in the ground. A more effective way to solve the Mach tuck problem was to equip the P-38 with dive flaps that could quickly be extended downwards and influence the center of pressure on the plane in a manner that would prevent it from nosing down. In late 1943 these flaps became standard on all new P-38s, and the company issued kits so that they could be retrofitted to already operational planes.

Alexander Lippisch knew about compressibility and Mach tuck, and he designed the Komet with relatively thin delta wings. The thin wings (at least in comparison to other contemporary planes) resulted in less acceleration of the air flowing over them, which contributed greatly to a high critical Mach number. The delta shape, or rather the swept wing in general, was another revolutionary good idea for high-speed flight. The most important factor in creating shocks on a wing is the velocity of the airflow perpendicular to the leading edge. If a wing is swept backwards, the component of the velocity perpendicular to the leading edge is diminished even if the total velocity remains the same. Or in other words, the air is presented with a more gradual change in wing thickness as the wing is swept back. This means that for the same thickness, shock waves will build up at higher speeds and thus the critical Mach number of the wing is increased. Another benefit of swept-back wings for supersonic flight is that they remain out of the V-shaped shock wave that forms at the nose of a plane when it exceeds the speed of sound. Straight wings partly project through this shock wave and this produces high drag. The downside is that the more a wing is swept back the less lift if will generate at any given velocity, reducing its effectiveness, especially at low speeds. The triangular shape of a delta wing combines wing sweep with a stronger structure that is supported by a longer section of the plane’s fuselage. As a result, the wing is more capable of resisting the strong force of high-speed flight. Moreover, at high angles of attack a delta wing creates a vortex of air which is able to stick to its surface much better than a normal straight airflow, thereby delaying wing stall. This is very handy at low flight speeds, where a delta-winged airplane can fly at a higher angle of attack and create more lift than a plane with normal swept wings. A delta wing is therefore efficient for high-speed flight as well as take-off and landing, as demonstrated by the excellent flying characteristics of the Me 163.

The combination of a relatively thin wing and its delta shaped planform gave the Komet a critical Mach number of about 0.84, so that it experienced transonic effects only at a much higher velocity than the P-38 or even the P-51, the latter of which had a critical Mach number of 0.78. This was very important, since even in level flight the Komet could fly much faster than a diving Lightning or Mustang and could more readily run into trouble. In addition a delta-winged aircraft needs no horizontal stabilizers, which saves weight and eliminates a source of drag. But the need for a high critical Mach number meant that the Me 163 had very little ‘washout’. Most wings on conventional airplanes are twisted so that the tip encounters the air at a lower angle of attack than the root. This is done to make sure that when the wing stalls it does so at the root first, leaving sufficient effectiveness for the ailerons near the wingtip (where they have the biggest leverage) to control the plane. The wing’s twist is called ‘washout’, and it is particularly important for swept wings since they more readily stall at the tip, causing the wing to drop and potentially result in a spin. Sufficient washout on the Me 163 would have caused the lower surface of its wingtips to shock stall at high speeds and bring on Mach tuck. To keep the tips from stalling at low speeds and high angles of attack in spite of the lack of washout, Lippisch installed fixed leading edge slots that would suck air from below the wing and pass it over the wingtips, thus delaying their stall.

Because the Me 163 flew much faster than propeller fighters and could surpass Mach 0.84 even in level flight, compressibility and Mach tuck remained a danger in spite of Lippisch’s revolutionary wing design. In comparison to modern supersonic planes, the wings of the Me 163 were still relatively thick. When flying the Me 163A Heini Dittmar was the first pilot to encounter the now familiar problems associated with supersonic flight. In his book Raketenjager Me-163, former Me 163 pilot Mano Ziegler quotes Dittmar regarding his record-setting flight of October 1941: “When I looked at the instruments again, I had gone over the 1,000 km per hour mark, but the airspeed indicator was unstable, the elevator started to vibrate, and at the same time the aircraft plummeted out of the sky, gathering speed. I could not do anything. I immediately turned off the engine and was certain that the end was near when I

|

Leading edge slot of the Science Museum’s Me 163 in London [Michel van Pelt].

|

suddenly felt the steering responding and managed to get the Me out of her nose-dive relatively easily.” To prevent pilots from exceeding the critical Mach number, a red warning light was installed in the cockpit to tell them when it was time to throttle down. However, while accelerating horizontally just before the sharp climb, or when leveling off in preparation for attacking enemy bombers, pilots tended not to look at their cockpit display very often, so later an alert horn was positioned right behind the pilot’s head to gain their attention.

After the war, other high-speed tailless airplanes with relatively thick wings had similar Mach tuck problems. The British de Havilland D. H. 108 Swallow research aircraft killed three pilots, including Geoffrey de Havilland, son of the company’s founder, because of its nasty Mach tuck characteristics. The American Northrop X-4 experienced similar difficulties during flight tests. Later tailless combat aircraft had thinner wings and better designed elevons that were shaped to prevent the loss of control power.

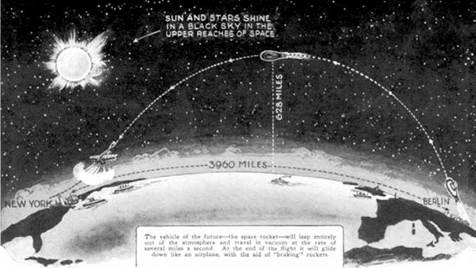

In his book, Mano Ziegler claims that during a flight in July 1944 Heini Dittmar actually broke the sound barrier in an Me 163B and reached a flight speed of 1,130 km per hour (702 miles per hour) by placing his Komet into a steep powered dive. Several observers on the ground are reported to have heard the sonic boom. If they indeed heard this, it would be positive proof of the plane flying faster than sound. A sonic boom is created by the pressure waves a plane causes by moving through the

|

Sound waves from a plane flying faster than the speed of sound create a shock wave that causes the ‘sonic boom’.

|

air, similar to the bow and stern waves of a boat. These waves travel away from the airplane at the speed of sound, so when the plane flies at Mach 1 or higher the waves are forced together and merge into a single shock wave in the shape of a cone which has the aircraft at its apex. When that wave reaches your ear as a sharp increase and following decrease in air pressure, you hear a bang. However, modern analysis of the Me 163 design shows that it was incapable of surpassing the speed of sound because its wings were too thick and its fuselage not slim enough. As the Komet got close to Mach 1, the resulting strong shock waves would create so much drag that the aircraft would not be able to accelerate further, even in a powered dive (shock waves require energy to form, and this is taken from the aircraft’s speed and creates a form of aerodynamic drag). The speed registered by Dittmar was very likely inaccurate, as indicators designed for subsonic airspeeds cannot measure transonic velocities very well. So the noise heard by the spectators was probably not the fully developed sonic boom associated with faster-than-sound flight.

As with all German ‘wonder weapons’, the Me 163B Komet was too little and too late to change the outcome of the war. Due to enemy raids on their airfields, the lack of rocket propellant, and the constant need to retreat, Komet pilots managed to shoot down only eight bombers and a single Mosquito reconnaissance aircraft. The cost to JG 400 was high, with many aircraft and pilots lost due to exploding engines and rough landings ending in deadly crashes, or because they were shot down. Overall, the Komet represented more of a threat to its own pilots than to the enemy. Nevertheless the Me 163B was the fastest plane in the sky during the Second World War, and had it been deployed earlier it would have made a much bigger impact than it did. The Komet was the first, and last, pure rocket propelled airplane ever to fly in combat.

As the war neared its conclusion, a more advanced rocket fighter, the Me 263, was already under development. Although based on the Me 163B it would have a proper retractable undercarriage with a nose wheel, a larger and better shaped fuselage, a greater propellant load and a pressurized cockpit with a bubble canopy for allaround vision. It would initially be powered by a new HWK 109-509C Walter rocket engine with two combustion chambers and nozzles, mounted one above the other. The larger chamber would provide power for take-off and climbing (and at 20,000

Newton was much more powerful than the engine of the Me 163B) whilst the smaller chamber would provide a lower thrust of 4,000 Newton for cruising and the return to base. In that way the plane would be able to fly under power and spend significantly longer attacking bombers than was possible for the Me 163B. The smaller chamber was also to enable the Me 263 to taxi to a safe shelter, making it less vulnerable on the ground (this smaller part of the engine was tested on two experimental Me 163Bs). The new plane would have the same wings and tail as the Komet, and so have a similar critical Mach number. One vital difference however, was that some of the propellant would be stored in tanks fitted in an empty space in the wings.

Because Messerschmitt was totally overloaded with production demands for its conventional fighter planes, the project was assigned to the Junkers aircraft company, which renamed it the Ju 248 and developed it under the leadership of Dr. Heinrich Hertel. Three prototypes were built, and the first one made several unpowered flights under tow by Messerschmitt Bf 110 twin-engined fighter aircraft before testing was halted by a shortage of fuel for the tow plane. It appears no powered flights with the Me 263 were made before the war ended.

After Germany’s capitulation, many Komets were removed to Britain, the US and Russia for analysis and tests. None of these were ever flown under power, mostly due to unfamiliarity with the rocket engine and its dangerous propellants. It is likely that the revolutionary airplane simply scared most of the potential test pilots. Ten of the expropriated planes survive (most of which were once part of JG 400) and are on display in museums in Britain, Germany, the US, Canada and Australia. During the restoration of one in Canada in the late 1990s it was discovered the aircraft had been sabotaged by the French laborers who had been forced to build it. They had wedged a small stone in between the fuselage fuel tank and a supporting strap in an attempt to cause a dangerous leak, and they had also weakened the wooden wing structure by using contaminated glue. On the inside of the fuselage they had written in French “Plant Closed” and “My heart is not occupied”. This particular Me 163B can now be seen in the National Museum of the United States Air Force near Dayton, Ohio. In the mid-1990s a former Luftwaffe pilot built an unpowered glider reproduction of the Komet which flies very well and from a distance looks very much like the real thing (its internal construction and the materials used are very different). The builder, Josef Kurz, had been in training to fly the Me 163B near the end of the war but never flew it. He made the first flight in his replica in 1996, being towed into the air by another plane. He later sold his Komet reproduction to the large European aircraft company EADS, one institutional strand of which could trace its roots back to none other than Willy Messerschmitt.

The original Komet hanging from the ceiling in London’s Science Museum now looks somewhat dusty, silent and inert: no longer advanced and top secret, merely an artefact of a war which was fought long ago. Just like a stuffed jaguar, it is initially hard to imagine that this display item was once an agile and terrifying hunter; a killer that could leap up to attack its victims high in the sky in an unprecedented manner, digesting toxic liquids and spitting fire. Suspended next to the museum’s Hurricane and an early Spitfire fighter, it looks rather diminutive, but it could readily out – climb, outrun and outmaneuver these conventional propeller planes that entered

|

Me 163B of the National Museum of the US Air Force [National Museum of the US

Air Force].

|

service only a few years before the Me 163B took to the sky. But if you look more carefully you cannot help but admire its sleek shape, the audacity of its design, and the pilots who dared to strap themselves into those dangerous little machines. They zoomed through the air at what were then utterly amazing speeds, in machines powered by incredibly dangerous propellants. A punctured propellant tank from a bullet or a rough landing would probably be fatal. On the one hand these machines were part of the jet age in terms of aerodynamic sophistication and propulsion technology, yet the construction technology and primitive landing skid clearly belonged to the realm of Second World War propeller aircraft. Its wooden wings and fabric-covered control surfaces would normally even be associated with planes of the First World War! The Komet pilots were the kings of the sky while they had propellant in their tanks (and provided their plane did not spontaneously explode), flying and climbing even faster than the early jets, but once out of power they found themselves in a glider that could be shot down by conventional fighters.

The Me 163’s legacy of advanced aerodynamics based on the delta-wing, tailless design led to such fast vehicles as the Concorde and the Space Shuttle, and it lives on in today’s advanced fighter aircraft. After the war Lippisch, the 163’s chief designer, was moved to the US as part of Operation Paperclip (along with von Braun and his A4/V2 team). There he continued his work at the Convair airplane company, which subsequently produced delta-wing airplanes such as the XF-92, F-102 Delta Dagger, F-106 Delta Dart, B-58 Hustler and the Navy’s F2Y Sea Dart. One Me 263

prototype was taken to the US. After Soviet forces captured the Junkers factory another ended up in Russia, along with some technical staff and engineering documentation. It formed the basis for the Soviet MiG 1-270 (to be discussed later). Walter and his technology were captured by the British, and later gave rise to the powerful engine that pushed the Black Arrow rocket into space, as well as the Spectre engine of the Saunders-Roe SR.53 rocket interceptor (also to be discussed later). And his ‘cold’ rocket pods were developed into the Sprite engine that de Havilland designed to assist aircraft take off from airports located in hot places and at high elevations where the low air pressure prevented the wings from generating sufficient lift. A pair of Sprites were tested on a Comet jet airliner in 1951.

The only Alhed pilot ever to fly the Komet under power was the famous British test pilot Eric Brown, who assessed the astonishing capabilities during a single flight of a captured plane in Germany shortly after the surrender. He later commented: “I was struck by how small it was, and yet how elegant it looked, and at the same time how very lethal. Lethal not only to the enemy, but to those who flew it.” Brown flew no fewer than 487 types of aircraft, not even counting different versions of the same basic type, so his judgment can be trusted.