By mid-1975 the reusable spacecraft had moved to the foreground as the next major step in the Soviet manned space program. Based on the evidence currently available, it would seem this decision was made mainly under pressure from the Soviet military community, which was becoming increasingly worried about the military potential of the US Space Shuttle. These concerns seem to have been triggered by several studies made at Soviet research institutes, including TsNIIMash. TsNIIMash specialists came to the conclusion that the Space Shuttle would never become economically viable if it was only used for the goals that NASA officially announced. As TsNIIMash director Yuriy Mozzhorin later said:

“[The Space Shuttle] was announced as a national program, aimed at 60 launches per year… All this was very unusual: the mass they had been putting into orbit with their expendable rockets hadn’t even reached 150 tons per year, and now they were planning to launch 1,770 tons per year. Nothing was being returned from space and now they were planning to bring down 820 tons per year. This was not simply a program to develop some space system… to lower transportation costs (they promised they would lower those costs tenfold, but the studies done at our institute showed that in actual fact there would be no cost savings at all). It clearly had a focused military goal.’’

In their opinion the Shuttle’s 30-ton payload-to-orbit capacity and, more significantly, its 15-ton payload return capacity, were a clear indication that one of its main objectives would be to place massive experimental laser weapons into orbit that could destroy enemy missiles from a distance of several thousands of kilometers. Their reasoning was that such weapons could only be effectively tested in actual space conditions and that in order to cut their development time and save costs it would be necessary to regularly bring them back to Earth for modifications and fine-tuning [13].

A study often cited with respect to the origins of the Soviet shuttle program was performed at the Academy of Sciences’ Institute of Applied Mathematics (IPM). Headed since 1953 by Mstislav Keldysh (President of the Academy of Sciences from 1961 to 1975), this institute had been involved in mission modeling and ballistics computations since the early days of the space program. The IPM studies were conducted under the leadership of Yuriy Sikharulidze and Dmitriy Okhotsimskiy, two of its leading scientists.

The IPM studies focused on the Shuttle’s possible use as a bomber, more particularly its capability to launch a nuclear first strike against the United States. Efraim Akin, one of the institute’s scientists, later recalled:

|

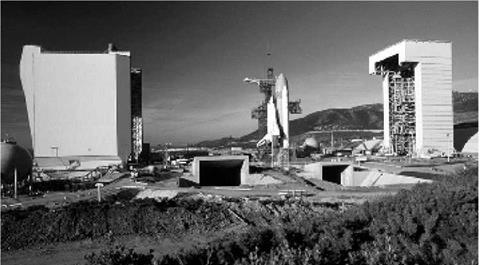

Space Shuttle Enterprise during pad tests at Vandenberg.

|

“When the US Shuttle was announced we started investigating the logic of that approach. Very early our calculations showed that the cost figures being used by NASA were unrealistic. It would be better to use a series of expendable launch vehicles. Then, when we learned of the decision to build a Shuttle launch facility at Vandenberg for military purposes, we noted that the trajectories from Vandenberg allowed an overflight of the main centers of the USSR on the first orbit. So our hypothesis was that the development of the Shuttle was mainly for military purposes. Because of our suspicion and distrust we decided to replicate the Shuttle without a full understanding of its mission.

When we analysed the trajectories from Vandenberg we saw that it was possible for any military payload to re-enter from orbit in three and a half minutes to the main centers of the USSR, a much shorter time than [a submarine-launched ballistic missile] could make possible (ten minutes from off the coast). You might feel that this is ridiculous but you must understand how our leadership, provided with that information, would react. Scientists have a different psychology than the military. The military, very sensitive to the variety of possible means of delivering the first strike, suspecting that a first-strike capability might be the Vandenberg Shuttle’s objective, and knowing that a first strike would be decisive in a war, responded predictably’’ [14].

The report produced by the IPM scientists has never been made public, leaving unanswered many questions about the technical details of such a mission. Apparently, the Russians believed the Shuttle could drop bombs on Soviet territory while re-entering from a single-orbit mission from Vandenberg or by briefly “diving’’ into the atmosphere and then returning to orbit. As Energiya-Buran chief designer Boris Gubanov writes in his memoirs:

“The studies… showed that the Space Shuttle could carry out a return maneuver from a half or single orbit…, approach Moscow and Leningrad from the south, and then, performing… a “dive”, drop in this region a nuclear charge, and in combination with other means paralyze the military command system of the Soviet Union.” [15]

What lent this scenario particular credibility from the Russians’ perspective was the Shuttle’s 2,000 km cross-range capability, demanded by the Air Force to enable the Shuttle to return to Vandenberg after a single orbit around the Earth. However, such single-orbit missions from Vandenberg were not considered for a nuclear strike against the Soviet Union, but to quickly service polar-orbiting US spy satellites or even pluck enemy satellites from orbit, barely giving the Russians a chance to detect such operations with their space-tracking means [16]. Leaving aside the question whether such missions were feasible, the capability to return to Vandenberg after a single revolution was needed anyway to allow the Shuttle to perform a so-called “Abort Once Around’’ in case it ended up in an unacceptably low orbit after a main engine failure.

One can only guess what led the Russians to believe that the Shuttle had a nuclear first-strike capability. Possibly, they were “inspired” by their own plans for a so – called Fractional Orbit Bombardment System, an orbital nuclear weapons system designed to attack the US via the South Pole rather than passing through the net of radar systems at the northern approach corridor. The Soviet Union worked on three such systems in the 1960s, one of which (using Yangel’s R-36 missile) actually reached operational status by the end of the decade.

Even though it bordered on paranoia, IPM’s assessment of the Shuttle’s first-strike capability is said by many to have been a decisive factor in convincing the Soviet leadership of the need to build an equivalent system (although a more rational reaction would probably have been to upgrade anti-missile defense systems). Gubanov writes:

“On the basis of the results of the analysis, M. V. Keldysh sent a report to the Central Committee of the Communist Party, as a result of which L. I. Brezhnev, actively supported by D. F. Ustinov, took the decision to work out a set of alternative measures to guarantee the safety of the country.’’ [17]

However, new evidence shows that Keldysh put his signature under the IPM report on 26 March 1976, which was more than a month after the official party and government decree that sanctioned the Soviet shuttle program [18]. Still, it cannot be ruled out that the studies began well before that time and that preliminary results did play some role in the Soviet decision to move forward with a Space Shuttle equivalent.

|

Mstislav Keldysh.

|

Keldysh, an influential figure in the Soviet space program until his death in 1978, seems to have been a major supporter of a Soviet shuttle system, which may seem surprising given his background as a scientist. However, rather than being a stereotypical armchair scientist, Keldysh had always been keen on putting his mathematical talents to practical use, making major contributions to Soviet strategic programs in his capacity as head of NII-1 (1946-1955) and IPM (1953-1978). His appointment as President of the Academy of Sciences in 1961 was seen as symbolizing the marriage of the Academy as the headquarters of fundamental science to the military-industrial complex. One joke that reportedly circulated among scientists was that “instead of representing the Academy in the Central Committee, Keldysh represented the Central Committee in the Academy” [19]. Roald Sagdeyev, the former head of the Academy’s Institute of Space Sciences, recalls how Keldysh reacted when an Academy workshop was asked to formulate an opinion on the need to develop a shuttle:

“Though we tried very hard, the workshop was unable to find even one single scenario in which the shuttle could provide a comparative advantage. Finally, I drafted a negative response to the government’s request for the Academy of Sciences’ opinion, in which I stated that the Academy did not see any sensible way to use this Russian version of the shuttle. Cautious Keldysh, however, did not want to get into conflict with the military, so he modified my wording, saying: ‘We do not see any sensible scenario that would support the shuttle for scientific uses [author’s stress]’.” [20]