Simulation in the X-15 program meant much more than pilot training. It was perhaps the first program in which simulators played a major role in the development of an aircraft and its flight profiles. The flight planners used the simulators to determine heating loads, assess the effects of proposed technical changes, abort scenarios, and perform a host of related tasks. In this regard, the term "flight planner" at the AFFTC and FRC encompassed a great deal more than someone who sat down and wrote out a plan for a launch lake and a landing site. It is very possible that the flight planners (such as Elmore J. Adkins, Paul L. Chenoweth, Richard E. Day, Jack L. Kolf, John A. Manke, and Warren S. Wilson at the FRC, and Robert G. Hoey and Johnny G. Armstrong at the AFFTC) knew as much as (or more than) the pilots and flight-test engineers about the airplanes.-12!

The initial group of X-15 pilots worked jointly with research engineers and flight planners to

develop simulations to study the aspects of flight believed to present the largest number of potential difficulties. During late 1956, North American developed a fixed-base X-15 simulator at their Inglewood facility that consisted of an X-15 cockpit and an "iron bird" that included production components such as cables, push rods, bellcranks, and hydraulics. The iron bird looked more or less like an X-15 and used flight-representative electrical wiring and hydraulic tubing, but otherwise did not much resemble an aircraft. The simulator included a complete stability augmentation system (dampers), and ultimately added an MH-96 adaptive flight control system. Controlling the simulator were three Electronics Associates, Inc. (EAI) PACE 231R analog computers that contained 380 operational amplifiers, 101 function generators, 32 servo amplifiers, and 5 electronic multipliers. None of the existing digital systems were capable of performing the computations in real time, hence the selection of analog computers. The simulator could also compute a real-time solution for temperature at any one of numerous points on the fuselage and wing. Simulations were initiated in October 1956 using five degrees of freedom, and the simulator was expanded to six degrees of freedom (yaw, pitch, roll, and accelerations vertically, longitudinally, and radially) in May 1957.[3]

X-15 FLIGHT SIMULATION

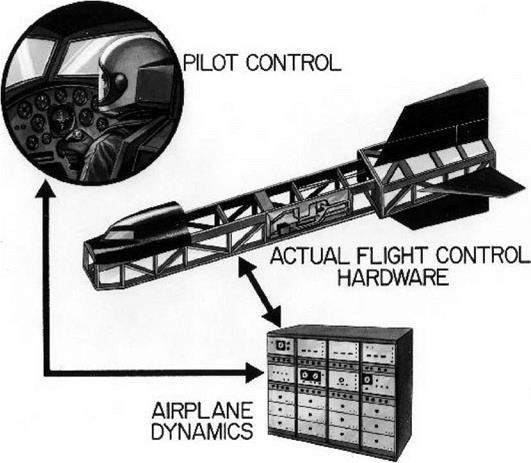

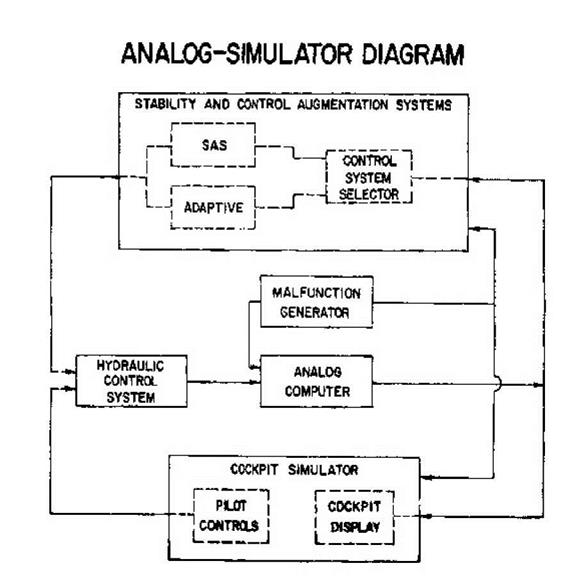

Simulation in the X-15 program meant much more than pilot training and was the first program where simulators played a major role in the development of the aircraft and its flight profiles. Engineers used the simulators to determine heating loads, the effects of proposed technical changes, and to develop abort scenarios. Controlling the simulator were three Electronics Associates, Inc. (EAI) PACE 231R analog computers that contained 380 operational amplifiers, 101 function generators, 32 servo amplifiers, and 5 electronic multipliers. None of the existing digital systems was capable of performing the computations in real time, hence the selection of analog computers. (NASA)

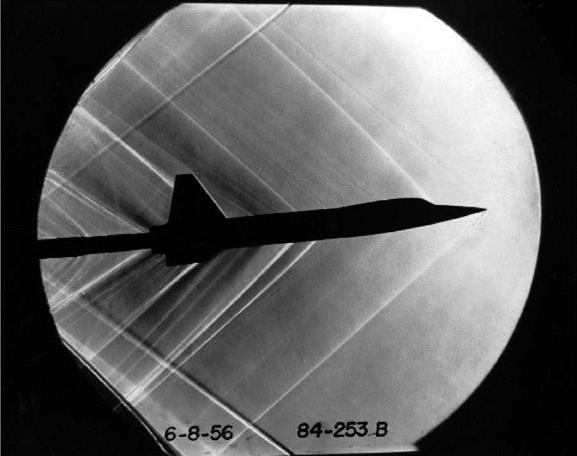

The simulator covered Mach numbers from 0.2 to 7.0 at altitudes from sea level to 1,056,000 feet (200 miles), although it was not capable of providing meaningful landing simulations. The initial round of simulations at Inglewood showed that the X-15 could reenter from altitudes as high as 550,000 feet as long as everything went well. If done exactly right, a reentry from this altitude would almost simultaneously touch the maximum acceleration limit, the maximum dynamic pressure limit, and the maximum temperature limit. The slightest error in piloting technique would exceed one of these, probably resulting in the loss of the airplane and pilot. An angle of attack of 30 degrees would be required with the speed brakes closed, or only 18 degrees with the speed brakes open. The normal load factor reentering from 550,000 feet would reach 7 g, and a longitudinal deceleration of 4 g would last up to 25 seconds. Simulations in the centrifuge confirmed that pilots could maintain adequate control during these maneuvers, and considerations for the physical well-being of the pilot did not limit the flight envelope.-^

These first simulations indicated the need for a more symmetrical tail to reduce aerodynamic coupling tendencies at low angles of attack, and potential thrust misalignment at high velocities and altitudes. This resulted in the change from the vertical-stabilizer configuration proposed by North American to the one that was actually built. Reentry studies indicated that the original rate – feedback-damper configuration was not adequate for the new symmetrical tail, and an additional feedback of yaw-rate-to-roll-control (called "yar") was required for stability at high angles of attack.-51

Initially, the North American fixed-base simulator was computation-limited, and researchers could only study one flight condition at a time. The first three areas investigated were the exit phase, ballistic control, and reentry. Later, upgrades allowed complete freedom over a limited portion of a mission, and by mid-1957 unlimited freedom over the complete flight regime. By July 1958, the fixed-base simulator at North American already had over 2,000 simulated flights and more than 3,500 hours of experience under various flight conditions, and the airplane would not fly for another year.

As crude as it may seem today, the simulator nevertheless provided the flight planners with an excellent tool. The flight planner first established a detailed set of maneuvers that resulted in the desired test conditions. He then programmed a series of test maneuvers commensurate with the flight time available to ensure that the maximum amount of research data was obtained. Since the simulator provided a continuous real-time simulation of the X-15, it enabled the pilot to fly the planned mission as he would the actual flight, allowing him to evaluate the planned mission from a piloting perspective and to recommend changes as appropriate. Certain data, such as heating rates and dynamic pressures, required real-time computations to verify that the desired maneuvers were within the capability of the airplane.-61

|

|

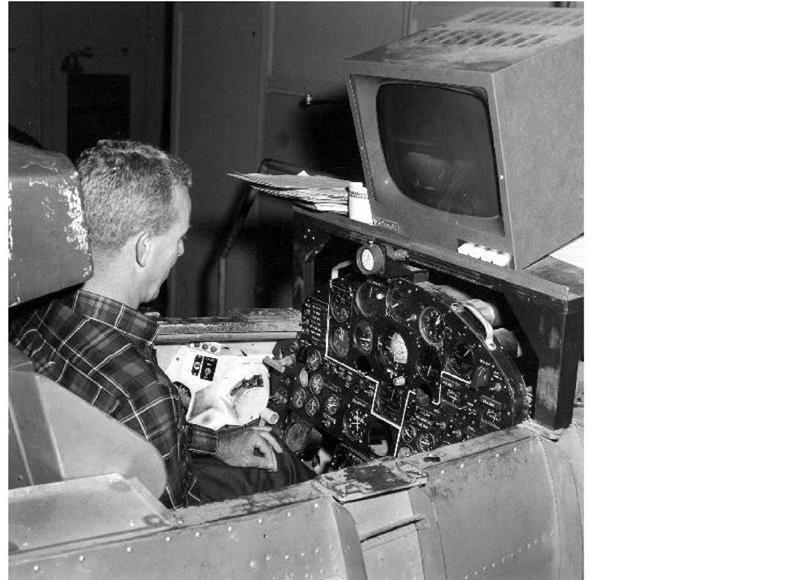

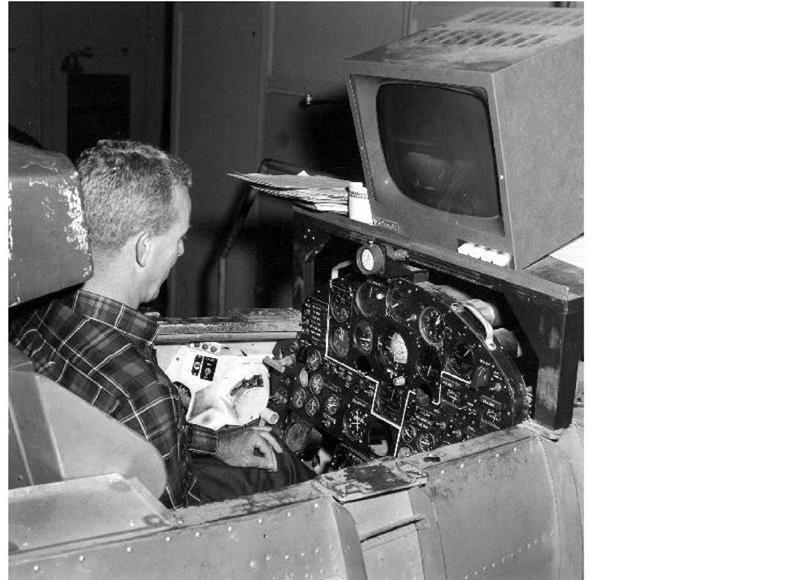

The fixed-base simulator at North American was hardly a fancy affair, just a mocked-up cockpit with a full set of instruments and a television screen. The original cadre of pilots, including Joseph A. Walker, spent a considerable amount of time in the North American simulator before the one at the Flight Research Center was ready. Although crude by today’s standards, the X-15 pioneered the use of simulators not just to train pilots, but also to engineer the aircraft, plan the missions, and understand the results. Not surprisingly, given the involvement of Charlie Feitz, Harrison Storms, and Walt Williams in both the X-15 and Apollo programs, the X-15 pointed the way to how America would conduct its space missions. (NASA)

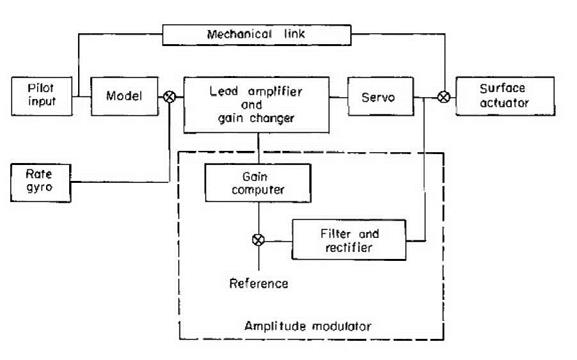

Engineers also used the simulator to develop vehicle systems before committing them in flight. One of the most notable was the MH-96 adaptive flight control system. Exhaustive tests in the simulator, conducted largely by Neil Armstrong, allowed researchers to optimize system parameters and develop operational techniques. Similarly, engineers used the simulators to investigate problems associated with the use of the dampers, and devised modifications to install on the airplane. Researchers then incorporated the results of flight tests into the simulator.-171

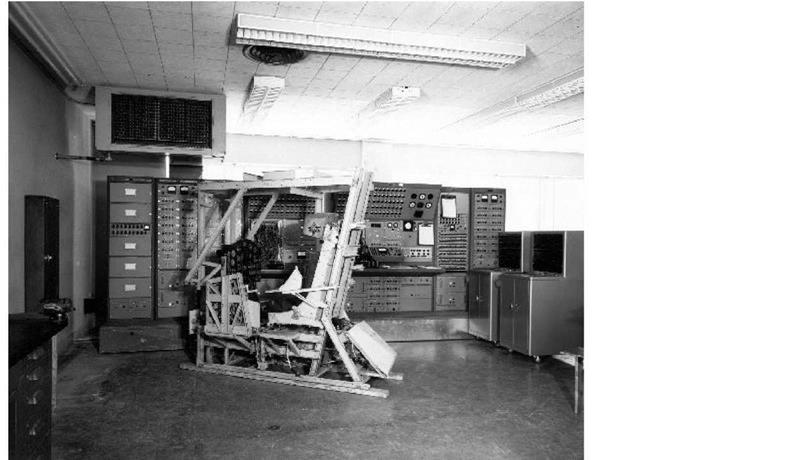

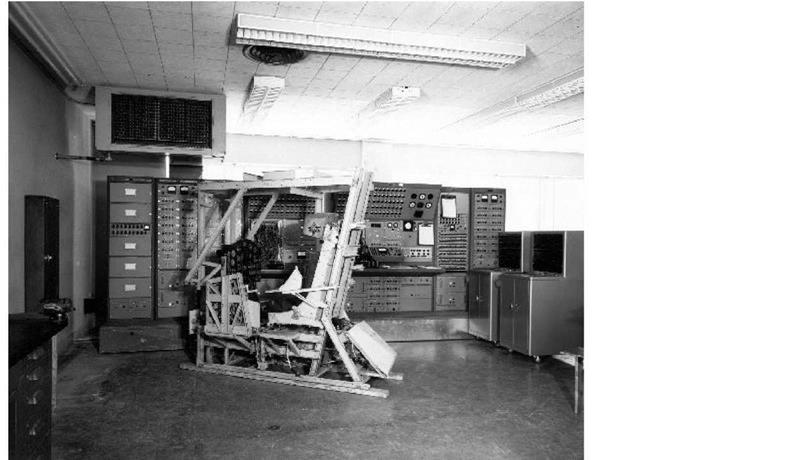

(excepting the computers) to the FRC before turning the first airplane over to the government. Unlike the Inglewood installation, at the FRC the cockpit and analog computers were in the same room: not much to look at, but functional. The Air Vehicle Flight Simulation Facility was located in building 4800 at the FRC in an area that later became the center director’s office. Like many early computer rooms, it used a linoleum-covered plywood false floor to cover the myriad of cables running beneath it. Large air conditioners installed on the building roof kept the computers cool. The X-15 simulator used a set of EAI analog computers procured for earlier simulations at the FRC, including one model 31R, one 131R, and one 231R that were generally similar to the computers used by North American. John P. Smith had begun mechanizing the original equations in the simulator, but Gene L. Waltman completed the task during the last three months of 1960 after Smith was promoted to a new job. The X-15 simulator became operational at the FRC on 3 January 1961. The X-15 simulator was the largest analog simulation ever mechanized at the FRC. The initial Air Vehicle Flight Simulation Facility at the FRC cost $63,000 and upgrades accounted for a further $1,700,000 by the end of 1968.-8

Because the FRC simulator was not yet operational, the flight planning for the first 20 flights used the North American simulator. Dick Day and Bob Hoey spent a considerable amount of time during 1959 and 1960 in Inglewood on flight planning and training the first cadre of pilots.-9 Initially, North American was to transfer the simulator from Inglewood to the FRC in January 1961, but the move was delayed for various reasons, including the need to integrate the MH-96 adaptive flight control system into X-15-3. By March 1961, however, Paul Bikle was becoming concerned: "With the performance envelope expansion program now underway, the requirement of traveling to NAA [North American Aviation] to use the X-15 simulator is becoming unduly restrictive in time and in obtaining the close working relationships essential to a sound flight panning effort." Something needed to change.-10

Bikle knew that North American did not want to transfer the simulator until the MH-96 integration was complete. In an effort to determine the consequences of moving earlier, Bikle called Dave Mellon at Minneapolis-Honeywell, who said he did not think the move would have an adverse affect on his schedule. Bikle also commented that "if a program delay is inevitable, it is preferable to delay the X-15-3 rather than the present program with the X-15-2." Bikle pushed to have the simulator moved to the FRC during April 1961. "We again want to emphasize that once the transfer has been accomplished, the NASA will make the simulator available for whatever additional simulator effort is required by NAA, M-H [Minneapolis-Honeywell], and other contractors…."-19

|

|

At first, the Flight Research Center made do with the crude cockpit that had been used in the centrifuge at NADCJohnsville. This was a cost-saving measure since the X-15 contract required North American to deliver their simulator (excepting the computers) to the FRC before turning the first airplane over to the government. Unlike the Inglewood installation, the cockpit and analog computers were in the same room at the FRC. The Air Vehicle Flight Simulation Facility was located in Building 4800 at the FRC in an area that later became the center director’s office. (NASA)

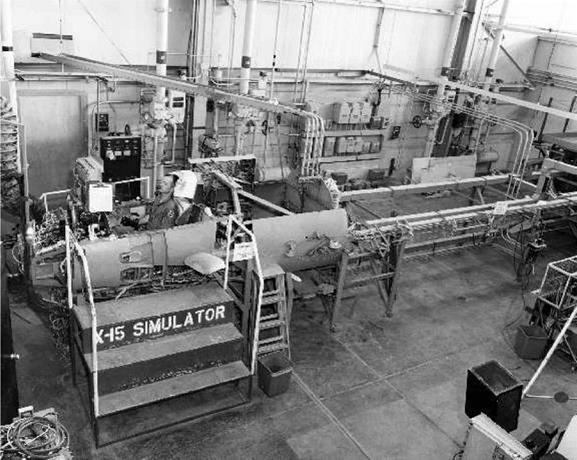

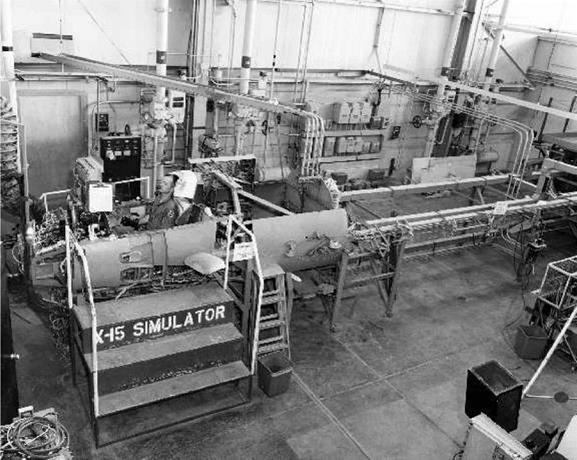

When the iron bird finally arrived in April 1961, engineers installed it along the east wall of the calibration hangar next door to the computer facility. A wall around the simulator provided some separation from the operations in the hangar. The cockpit faced away from the hangar door, and pilots discovered that sunlight coming through the windows caused visibility issues, so paint soon covered the windows. One of the unfortunate aspects of this installation was that the iron bird was located a little over 200 feet from the computers. This caused a number of signal-conditioning problems that a better grounding system eventually corrected. The hydraulic stand for the iron bird was originally located next to the mockup inside the hangar, but technicians subsequently relocated the unit to a small shed just outside, eliminating most of the noise from the simulator laboratory.-1121

To provide simulations that were more realistic, engineers at the FRC added a "malfunction generator" that could simulate the failure of 11 different cockpit instruments and 23 different aircraft systems. The instruments included a pressure altimeter, all three attitude indicators, and pressure airspeed, dynamic pressure, angle-of-attack, angle-of-sideslip, inertial altitude, inertial velocity, and inertial rate-of-climb indicators. The vehicle systems that could be failed included the engine, ballistic control system, both electrical generators, and any axis in the damper system. Later, the simulator could duplicate the failure of almost any function of the MH-96 adaptive control system. Almost all X-15 flights were preceded by practicing various emergency

|

procedures in the simulator using these malfunction generators.-1131

|

The final simulator at the Flight Research Center was functionally identical to the one at North American, and used the same analog computers. The structure behind the cockpit is the "iron bird" that included production components such as cables, push rods, bellcranks, and hydraulics. The iron bird looked more or less like an X-15 and used flight-representative electrical wiring and hydraulic tubing, but otherwise did not much resemble an aircraft. The simulator included a complete stability augmentation system (dampers), and ultimately added an MH-96 adaptive flight control system. (NASA)

Contrary to many depictions of flight simulators in movies, the fixed-base simulator for the X-15 was not glamorous. The iron bird stretched behind the cockpit, but other than in size, it did not resemble an X-15 at all. The cockpit was open, and the sides of the "fuselage" extended only high enough to cover the side consoles and other controls inside of it. A canopy over the cockpit became necessary when researchers installed some instruments and controls (particularly for the experiments) there for later flights, but even then, it was made of plywood.-141

However, unlike most of the previous simulators at the FRC, the X-15 cockpit did have an accurate instrument panel. On one occasion, technicians inadvertently switched the location of the on/off switches for the ballistic control system and the APUs between the simulator and the airplane. It was normal procedure for the pilot to turn off the ballistic controls after reentry, and he practiced this in the simulator before each flight. During the actual flight, the pilot reached for the APU switch instead of the switch he thought was there. Fortunately, he caught himself and avoided an emergency. Everybody redoubled their efforts to ensure that the simulator accurately reflected the configuration of the airplane.15

When X-15-3 came on line with a completely different instrument panel arrangement, it presented some challenges for the simulator. Since the pilots needed to train on the correct instrument panel layout, the simulator support personnel had to swap out instrument panels to accommodate each different airplane. The technicians eventually installed a crank and pulley lift in the ceiling, along with cannon plugs for the electrical connections, to assist in making the change. On at least three occasions the program decided to make the instrument panels in the three airplanes as similar as possible, but they quickly diverged again as new experiments were added.1161

In addition to its simulation tasks, the iron bird found another use as the flight program began. Engineers and technicians at the FRC soon discovered that it was a relatively simple task to remove troublesome components from the flight vehicles and install them on the iron bird in an attempt to duplicate reported problems. Given the initial lack of test equipment available for the stability augmentation system and some MH-96 components, this proved a useful troubleshooting method. The simulator also played an important role in demonstrating the need for advanced display and guidance devices, and found extensive use in the design and development of new systems.-1171

The simulator had a variety of output devices in addition to the cockpit displays, including several eight-channel stripchart recorders and a large X/Y flatbed plotter. The plotter had two independent pens: one showed the X-15 position on a 3-foot-square map of the area, and the other indicated altitude. This plotter was identical to ones used in the control room and at the uprange stations. There were different maps for each launch lake showing the various contingency landing sites and prominent landmarks.1181

Eventually the FRC simulator grew to encompass six analog computers, and the patch panels needed to operate them contained 500 patch cords. The addition of a Scientific Data Systems SDS-930 digital computer in 1964 allowed the generation of nonlinear coefficients for the X – 15A-2. This required an additional analog computer as an interface between the new digital computer and the rest of the simulator. The SDS-930 was somewhat unusual in that it was a true real-time computer, complete with a real-time operating system and a real-time implementation of Fortran.1191

Despite its advanced specifications the SDS-930 was not initially satisfactory, which forced the flight planners to use the modified Dyna-Soar hybrid simulator at the AFFTC for the early X-15A – 2 flights. The SDS-930 was generally unreliable, normally because of memory-parity errors that the computer manufacturer attempted to fix on numerous occasions during 1965, with little success. The problem was not only affecting flight planning for the X-15A-2, it was also delaying simulations needed for the energy-management system scheduled to fly on X-15-3. During early 1966, the SDS-930 was extensively modified to bring it up to the latest configuration, including the addition of two magnetic-tape units and a line printer to assist in the energy-management simulations. While this was going on, the FRC took advantage of the downtime to upgrade the SAS and ASAS implementation on the iron bird, including replacing all of the computer interface equipment for both systems. Technicians also brought all of the mechanical rigging up to the same standard as the three airplanes. However, Johnny Armstrong and Bill Dana both recall that no actual flight planning or flight simulation was "totally digital."1201

The hybrid (analog-digital) simulator at the AFFTC initially provided a tool that enabled studies of the performance and handling of the X-20 glider, complete mission planning, and pilot familiarization. It was a logical outgrowth of the analog fixed-base simulators for the X-15. Although they had been ordered long before, the digital computers did not arrive at Edwards until

July 1964, six months after the cancellation of the Dyna-Soar program. The equipment sat mostly unused until the flight planners decided to adapt it to the X-15A-2 Mach 8 flight expansion program. This was done as much to provide Air Force personnel with some hands-on experience as for any demonstrated need for another X-15 simulator.-1211

The analog section of the hybrid simulator used PACE 231R-V and 231R computers similar to those used at the FRC and North American installations. Each computer had approximately 75 operational amplifiers, 170 potentiometers, 36 digitally controlled analog switches, and 26 comparators, and the 231R-V had a mode-logic group that supported an interface to a digital computer. The digital subsystem used a Control Data Corporation DDP-24 that had 8,192 words of ferrite core memory, a 5-microsecond access time, and a 1-MHz clock. Although a Fortran II compiler was available on the machine, engineers coded the real-time programs in assembly language to maximize the performance of the relatively slow machines. Two large patch panels connected the analog subsystem and digital subsystem.-1221

|

|

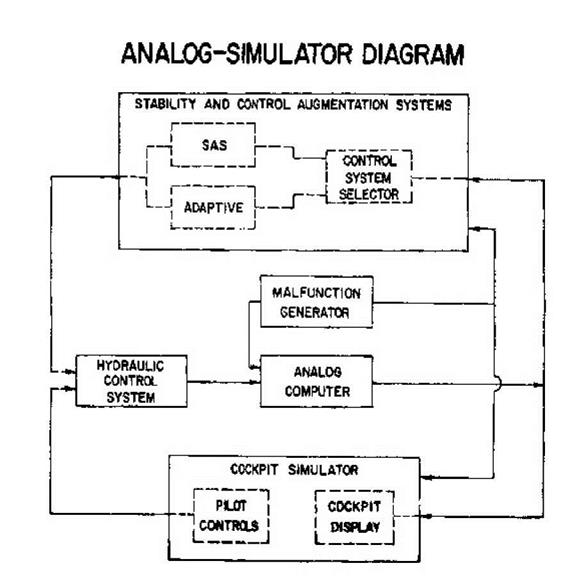

The fixed-base simulators at Inglewood and the FRC consisted of four major parts. The simulator included both controls and displays that were nearly identical to what the pilot found in the X-15 cockpit. The analog computer and malfunction generator were the heart of the system that provided the sequencing and control of the other components. The hydraulic control system was the "iron bird" and actually contained other flight components in addition to the hydraulic system including a complete stability augmentation system (or, later, a complete MH-96 adaptive flight control system). (NASA)

Like the other fixed-base simulators, the AFFTC device had a functional X-15 instrument panel, although it was not as exact as the ones used at the FRC. This was because its intended use was to investigate heating and control problems related to the X-15A-2, not to conduct pilot training. Ultimately, the program did use the AFFTC simulator for some X-15A-2 pilot training, but the final "procedures" training was conducted at the FRC.

Since the X-15 program technically did not need the simulator, the AFFTC engineers were able to develop a "generic" simulation that was usable for other aircraft, not just the X-15. This was an extremely astute idea, and the engineers subsequently used the simulator for the M2-F2, SR-71, X-24A, X-24B, and EF-111. The hybrid simulator was also the only one available to perform heating predictions during reentry simulations of the Space Shuttle Orbiter during the early 1970s, providing valuable input to that program.-123

At the FRC, the simulation team kept busy maintaining the computers and updating the programming to reflect actual flight results. During most of the flight program the simulation lab was busy for at least two shifts, and often three shifts, per day. The first shift performed pilot training and flight planning, the second shift conducted control-system and other studies, and maintenance and reprogramming occupied the third shift as needed. However, the team generally took weekends off. This was not necessarily a good thing for the simulator since it took the analog computers quite a while on Monday morning to warm up.-123

Despite the apparent success of the fixed-base simulators, everybody recognized their limitations. The primary concern was that they were fixed-base and not motion-base, and therefore were inappropriate for landing training. For instance, the lack of a high-quality visual presentation meant that critical visual cues were not available to the pilots. The analog computer also had limitations. For example, the precision needed to calculate altitude and rate of climb for the landing phase was not readily achievable with the parameter scaling used for the rest of the flight. The parameter scaling was critical, and analog computers were accurate to about one part in 10,000. For the X-15 simulation, with the altitude scaled such that 400,000 feet equaled 100 volts, one-tenth of a volt was equal to 40 feet. Any altitude less than this was down in the noise of the analog components and barely detectable. It was simply not possible to calculate accurate altitudes for the landing phase and the rest of the flight profile at the same time. All of this necessitated maintaining a fleet of Lockheed F-104 Starfighters as landing trainers, something the X-15 pilots did not seem to mind at all.-123

Nevertheless, Larry Caw and Eldon Kordes did mechanize a simple four-degrees-of-freedom simulation to study landing loads early in the program. The simulation only covered the last few seconds of a flight, and was not particularly useful as a pilot training tool. However, it allowed Jack McKay and other engineers to look at the variety of forces generated during an X-15 landing, and prompted the first round of landing-gear changes on the airplane.-126

The lack of a motion-base simulator presented several interesting problems. For instance, some phenomena experienced in the JF-100C variable-stability airplane during the summer of 1961 indicated that using the beta-dot technique in the X-15 might be more difficult than anticipated. Consequently, a cooperative program was initiated with NASA Ames to use its three-axis motion – base simulator. The objective was to investigate further the effect of g-loading on the pilot while he performed beta-dot recovery maneuvers. Four pilots-Forest Petersen, Bob Rushworth, Joe

Walker, and Bob White-participated in the tests during September 1961. Paul Bikle reported that, "With fixed-base simulation, the ventral-on condition was uncontrollable, using normal techniques; however, it could be controlled by using the special beta-dot control technique. With the moving cockpit simulation, control using either normal or beta-dot techniques was more difficult for the pilot than with the fixed-base cockpit simulation. These results were in general agreement with the ground and flight tests conducted with the variable-stability F-100 airplane."271

By the end of the X-15 program, the FRC had established simulation as an integral part of the flight program. Today, the Walter C. Williams Research Aircraft Integration Facility (RAIF) provides a state-of-the-art complex of computers, simulators, and iron-bird mockups. As an example of the extent to which simulations were used, during the X-33 program, pilot Stephen D. Ishmael flew countless missions while engineers evaluated vehicle systems, flight profiles, and abort scenarios. What is ironic is that the X-33 was to be an unmanned vehicle— Ishmael was just another computing device, one with a quick sense of reason and excellent reflexes.

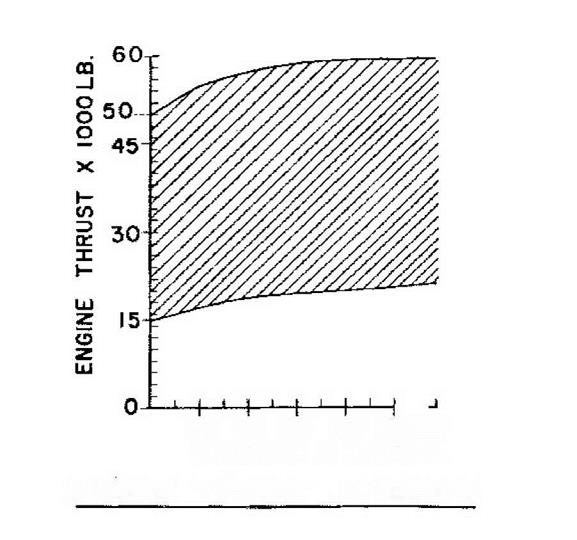

20 40 ЄО 80 100 а ALTITUDE X 1000 FT.

20 40 ЄО 80 100 а ALTITUDE X 1000 FT.