Although the X-15 would eventually play a major role in the Hypersonic Research Engine (HRE) project, researchers had not considered air-breathing propulsion at all during its conceptual development in 1954. At the time, most researchers believed that hypersonic air-breathing engines were improbable or, more likely, impossible. Several military programs undertook subsonic-burning ramjet development, but there appeared to be fundamental obstacles to their use at hypersonic speeds. In 1955, William H. Avery at the Applied Physics Laboratory (APL) of The Johns Hopkins University conducted a survey of ongoing ramjet development efforts and concluded that Mach 4 was about the highest speed achievable by ramjets. Two problems arose at higher speeds: the lack of structural materials for the combustor, and a serious energy loss due to dissociation of the propulsive airflow and the failure of this plasma to recombine in the nozzle.*230*

A remarkable change from pessimism to optimism occurred during the late 1950s and early 1960s. By 1964, researchers believed they could solve the problems encountered previously. In particular, a hydrogen-powered supersonic combustion ramjet appeared to have the dramatic potential of useful performance up to near-orbital velocities. No single breakthrough created this newfound optimism-it sprang from a confluence of results from a number of unrelated research efforts. The first important contribution was a series of external burning studies conducted at the NACA Lewis Flight Propulsion Laboratory and the Marquardt Corporation in Van Nuys, California. These studies appeared to confirm that combustion in a supersonic flow was possible. Similar results had been produced by the APL and Antonio Ferri at the Brooklyn Polytechnic Institute in the late 1950s. The next innovation was the development of hydrogen as a fuel, which was also mainly accomplished at Lewis. Beginning in 1954, Richard J. Weber at Lewis began to think about the possibility of using supersonic combustion, internally, in a ramjet engine. Although he doubted that shock-free combustion would be possible in a supersonic combustor, Weber decided to analyze the ideal performance that would be attainable in a ramjet. The work had a low priority and proceeded slowly, but resulted in the first definitive analytical assessment of a supersonic ramjet.-1231

In a September 1958 report, Weber and John S. Mackay identified several beneficial features of a supersonic combustion ramjet (scramjet), noting that it could relax inlet/diffuser requirements, reduce combustor heating, minimize the nozzle-dissociation problem, alleviate variable-geometry inlet requirements, and provide the potential for performance levels much higher than any other air-breathing engine at speeds above Mach 7. The effects of the combustor area ratio, thermal compression, and other design parameters were determined for the first time. Several other researchers generally confirmed the results of this research by 1960. Ironically, by the time NASA finally published the Weber-Mackay paper in 1958, the authors had moved on to other research, believing there would be little interest in the scramjets and few (if any) applications for them.[232]

This was an interesting time for the NACA laboratories. On 1 October 1958, the NACA ceased to exist and the new NASA came into being. Lewis was beginning to abandon all work on airbreathing engines in favor of rocket engines. Thus, it surprised Weber when in early 1959 he was invited to speak at the 2nd Symposium on Advanced Propulsion Concepts as a specialist in supersonic combustion. Weldon Worth, then technical director of the Aero-Propulsion Laboratory at Wright Field, organized an entire session on the subject. Worth had many interests, including Aerospaceplane, a large single-stage-to-orbit vehicle powered by scramjets. Shortly after the beginning of the Mercury program in 1959, most of the major aerospace companies participated in studies of the Aerospaceplane, although in retrospect it is easy to see that the concept could never have worked given the technology of the era. Nevertheless, the concept was exciting, and Alexander Kartveli at Republic Aviation, for example, enlisted the services of Antonio Ferri to collaborate on orbital concepts. In addition to scramjets, the companies began working on imaginative new schemes, such as the air collection engine system (ACES) and the liquid air collection and enrichment system (LACES), that would extract air from the atmosphere on the way up to be used as oxidizer by rocket engines when the vehicle left the sensible atmosphere.-1233

The first public discussion of hypersonic propulsion and its possible applications was held at the 4th AGARD Colloquium in Milan during April 1960. Ferri fired the imagination of his audience with the prospects of air-breathing engines that worked all the way to orbit. Many of the older researchers were politely skeptical. The Aerospaceplane concepts would survive for several years within the Air Force before everybody came to realize they were simply too advanced for the state of the art. For a brief time, however, they influenced the road taken by some of the early space shuttle studies.-1233

The scramjet concept, however, survived relatively intact. Between 1959 and 1963, the military spent $10 million on scramjet research, and researchers failed to uncover any "concept killer" obstacles. Perhaps equally important was the appearance of a rapidly growing cult of ardent scramjet enthusiasts of which Ferri was the chief spokesman and Worth the chief benefactor. By all appearances, it seemed that practical scramjet applications were just around the corner. One

1964 summary stated that "scramjets are passing into the development stage" and listed no less than 19 institutions that were working on the concept, including five that were "testing complete engine models."[235]

In 1964 the Air Force released Project Forecast, one of the periodic studies the military conducted into possible advanced concepts for future applications. Largely through the lobbying efforts of Ferri and Worth, the scramjet became an area that merited special emphasis. Consequently, General Bernard A. Schriever, the commander of the Air Force Systems Command, established a special task force to examine scramjet technology and its potential. However, the cards were stacked in favor of the technology because the majority of the members of the task force were members of Worth’s staff or representatives of the various contractors working under $22 million worth of scramjet contracts. The final report published in April 1965 envisioned "no unforeseen problems" and recommended initiating a high-priority national development program. There were, of course, skeptics who did not believe the technology was nearly as advanced as its proponents claimed. However, few of them were willing to buck the Air Force hierarchy, which apparently had decided to embark on a crusade.-1236

The origination of large government research and development projects is seldom a logical process, and the HRE was no exception. North American Aviation was always interested in new business, and during the early 1960s it was particularly keen on finding new ways to exploit the X-15 research airplane. Given the newfound interest in scramjet propulsion, project aerodynamicist Bill Johnston decided to marry the two. During May 1962, Johnston visited various Air Force and NASA centers with a proposal to modify an X-15 for use as a flying test bed for hypersonic air-breathing engines. To many researchers, including some at the FRC, the X-15 seemed like an ideal test bed for such a propulsion system. As envisioned by the FRC in 1961, this idea was "an extensive air-breathing engine development program… in which one or more sub-scale modular experimental engines would be flown in a true flight environment aboard the X-15." Surprisingly, there were no takers, and the proposal floundered until November 1962 when Jack McKay made an emergency landing in X-15-2, injuring himself and seriously damaging the airplane.-1237-

North American took this opportunity to dust off Johnston’s concept and reiterated its proposal to modify the airplane for propulsion testing. The Air Force supported the plan and was willing to pay the estimated $4.75 million to rebuild and modify the aircraft. Many within NASA, however, were not in favor of the idea since they considered the proposed Mach 8 speed to be of limited value for propulsion research. Nevertheless, NASA did not press its objections and the Air Force authorized North American to modify the airplane. It thus appeared that a Mach 8 carrier vehicle would be available within a couple of years; however, the propulsion test engines themselves were completely undefined.-1238

To correct this illogical situation, the FRC quickly launched a study aimed at determining what type of engine would be appropriate for testing on the X-15. Recognizing that the expertise for monitoring such a study would be found chiefly at other NASA facilities, the FRC solicited comments on its draft procurement documents; no support was forthcoming. In fact, Kennedy F. Rubert at Langley expressed his opposition to any flight program as "an unwise expenditure of government funds" since engine research "is better done on the ground." Undaunted, the FRC continued with its procurement and stated firmly that it planned "to take an active role in advanced air-breathing propulsion and the X-15 should prove very useful in this regard." This course of action seemed to both prolong the X-15 program and increase the participation of the FRC in basic research projects, despite philosophical misgivings on the part of many at the FRC, including Paul Bikle.[239]

After a brief proposal period, the FRC awarded a four-month study contract to the Marquardt Corporation to generate requirements applicable to 1) subsonic combustion ramjets, 2) LACES, 3) scramjets, 4) ducted rockets, and 5) turboramjets.[240]

When the final report appeared in December 1963, the results bore little resemblance to the dummy ramjet that would ultimately fly on X-15A-2. Marquardt determined that the X-15 was a viable platform for testing ramjets in the speed range of Mach 4 to Mach 8, providing a useful complement to ground testing. The company proposed to test three different types of ramjets that required 33 months to develop and build. Surprisingly, the study investigated using one of the basic X-15s for preliminary testing while North American rebuilt X-15A-2.4241

The three proposed engines included a subsonic combustion ramjet, a scramjet, and a "convertible ramjet," all sharing a common external design referred to as MA-131. The convertible engine operated as a subsonic combustion engine between Mach 3 and 5, and with supersonic combustion between Mach 7 and 8; it transitioned from one mode to the other between Mach 5 and 7. Researchers investigated three other engine types—the turboramjet, ducted rocket, and LACE/ACES-and ruled them out, although the ducted rocket returned as part of the later air – augmented rocket propulsion system (AARPS) concept.42424

Marquardt considered regenerative, radiation, and ablative cooling schemes, and settled on the latter as being the most cost-effective and lowest risk. Unfortunately, this probably doomed the Marquardt proposal since most hypersonic-engine researchers were firmly convinced that testing was not worthwhile unless the engine used regenerative cooling. Another controversial aspect of the Marquardt proposal was the plan to forego a true variable-geometry inlet design in favor of an inlet that could be set to various positions on the ground before flight. In retrospect, this seems like a good compromise. Undoubtedly, any production engine would use a variable-geometry inlet, but it would be expensive and time-consuming to develop one. In addition, given how short a period the X-15 could maintain steady flight conditions, there would be little opportunity to adjust the inlet in flight in any case. Ground personnel could adjust it to allow data to be gathered on successive flights at different geometries. Still, the researchers at Langley and Lewis believed the solution was inelegant and rejected it out of hand.-42434

The engineers at the FRC begged to differ, noting that "the elimination of complex and unproven inlet and exhaust nozzle control systems from the test engine also provides operational simplicity with reasonable assurance for success without a long and costly X-15 flight test program." Nevertheless, the engineers worried that the drag created by the ramjet installation might result in much slower-than-desired acceleration while on the way to the intended flight conditions. Marquardt modified the design so that the inlet would close during the acceleration phase and open only when the correct test conditions were available.-42444

Instead of the round cross-section dummy ramjet that ultimately hung from the ventral stabilizer on X-15A-2, Marquardt proposed a rectangular shape that fit flush against the lower fuselage. The unit would be 188 inches long, 24 inches wide, and 21 inches high. A boundary-layer fence between the inlet and the lower fuselage ensured clean airflow into the inlet. Researchers expected the hydrogen-fueled ramjet could produce up to 1,000 lbf gross thrust. Several mockups were produced and fitted to X-15A-2 at various times, including one airshow at Edwards.-12454

estimated that the Typhon installation would weigh 803 pounds, while the three Marquardt engines would average about 900 pounds. The engineers believed all of these were within the capability of the X-15 to handle, although they shifted the center of gravity dangerously rearward.[246]

In addition to the engine package itself, North American needed to install an engine control system, engine jettison system, liquid-fuel storage and transfer system, and fuel pressurization system, as well as a new fire detection system. The engine package would replace the ventral stabilizer on the basic X-15, but would hang from a stub ventral on X-15A-2.[247]

On the basic airplane the entire ventral stabilizer and lower rudder actuator would be removed, a "roller support system" would be installed that actually supported the ramjet, a new frame would be added in the fuselage at station 483.5, and a pair of conformal liquid-hydrogen slipper tanks would be added over the aft portions of the side tunnels. Since North American was including a liquid-hydrogen tank in the center-of-gravity compartment of the rebuilt X-15A-2, the slipper tanks would be unnecessary. The longer rear skids on the advanced airplane would also allow the ramjet to be mounted on the stub ventral stabilizer. This had a couple of desirable effects: the inlet would be farther away from the flow disturbance caused by the X-15 fuselage, and at least a small ventral stabilizer would remain if the ramjet had to be jettisoned at high speeds. North American also suggested using JP-Pentaborane as an alternate fuel, and proposed installing a system that could handle either fuel as necessary.-1248

North American did express a couple of concerns. The modifications would increase landing-gear loads significantly, reducing the factor of safety below the 150% normally maintained. The company suggested beefing up the landing gear on the basic X-15 at a minimum, and perhaps even strengthening the already beefier gear on the advanced airplane. A more disturbing concern was the aft center of gravity that would be created by the ramjet installation, particularly in the basic airplane where the liquid hydrogen (and, more importantly, its tankage) would be mounted far aft. North American advised performing a new series of stability and control wind-tunnel tests to determine how bad the situation might really be. Ultimately, researchers at the JPL conducted these tests during 1966 on both the basic airplane and the advanced X-15A-2.-249

Assuming a go-ahead in February 1965, North American estimated it would take three months to design the modifications to X-15-1, four months to fabricate the modification kit, and four months to install it, meaning that X-15-1 would be available to support hypersonic engine testing in January 1966. The advanced X-15A-2 would become available in July 1966. Researchers expected that the flight program would encompass approximately 25 flights spread over a two – year period.-1258

Hypersonic Research Engine

None of the NASA reviewers, excepting the FRC, believed a research program based on the Marquardt engine concept was justifiable. They pointed out that the emphasis on low cost would result in overly simplified designs that provided little valid test data. In addition, the use of ablative materials would produce contaminants that might strongly affect the combustion process. While discussing the problem with Kennedy Rubert, John Becker suggested that Rubert offer an alternative that might be worthwhile. Rubert then described, in general terms, a concept very close to what would eventually become the HRE-a sophisticated dual-mode engine that was thoroughly researched on the ground and used a clean internal metallic structure without ablative coatings. Becker argued that this was a superior alternative.-1251!

After the final Marquardt briefing at the FRC, Douglas E. Wall, who was in charge of X-15 research engine activities, called an informal meeting of the NASA participants to discuss the next move. The outside center reviewers were unanimously against the Marquardt engines, and generally against any flight program. Wall argued convincingly that financial support for an extensive scramjet program was unlikely to be forthcoming unless it was tied to an X-15 flight experiment. Although almost everybody still viewed a flight program as unnecessary, all agreed that Wall was probably correct. Everybody recognized, however, that Lewis would present a formidable obstacle; not only was Lewis traditionally unsympathetic to research airplanes, but the center had also recently abandoned almost all air-breathing engine research. To bypass the expected objections, the researchers decided to propose the Hypersonic Research Engine (HRE) program as a joint FRC – Langley effort, with Langley managing the ground phase and the FRC being responsible for the flight phase.-1252

Although he was personally unconvinced, Paul Bikle endorsed this concept and verbally presented it to NASA Headquarters, with Rubert recommended as the program manager. The initial Langley reaction, however, was unfavorable, mainly because Lawrence K. Loftin, Jr., one of the assistant center directors, had recently recommended against such a program. In Becker’s Aero Physics Division there was a very different reaction. For years, propulsion-related fluid mechanics and hypersonic inlet/diffuser work in the division had suffered from a dearth of real-life applications. The prospect of involvement with a real engine for X-15 testing offered an exciting infusion of much needed vitality. Becker also pointed out that the HRE project would reveal whether any of the performance claims for the scramjet were valid, something that appealed to many Langley managers. Another important consideration was the complete lack in 1964 of ground-test facilities for true-temperature simulation with clean air above Mach 5. Therefore, researchers viewed the X-15 as a unique test facility, and eventually Langley management came around and began supporting the project.-1252

NASA asked Rubert to develop a detailed plan for the HRE program, and on 17 March 1964 he released a preliminary proposal that outlined a three-phase program. Phase I was to define a practical, high-performance, Mach 3-8 hypersonic engine, and to design, develop, and build such an engine; Phase II was to measure the performance of the engine in the laboratory; and Phase III was to measure the performance of the engine in maneuvering flight and to validate the ground – test results. Significantly, the proposal did not discuss the need for scramjet research, assuming (incorrectly) that this was already well known. Rubert stated flatly that the "gaps" in component technology "had been filled," leaving only uncertainties "which can be discovered and resolved only by design and construction of a truly practical research engine." Nobody at Langley challenged these claims, which mainly demonstrated the inflated technical confidence in the concept that existed at the time. Rubert’s plan required four years at a cost of $30.4 million, plus the operations costs of the X-15. The proposal "sailed through" its approval process at NASA Headquarters "with no opposition and few questions asked." Significantly, Lewis director Abe Silverstein did not oppose the project, although he stopped short of actually supporting it. Phase I funds were released on 13 June 1964.[254]

As Wall had indicated, tying the HRE proposal to the X-15 lent credibility. The X-15 was still a successful program that enjoyed almost universal approval within NASA; anything related to it, by default, usually enjoyed similar approval. Of course, there should have been questions. Both the schedule and budget were hopelessly optimistic for developing an entirely new type of engine.

The lack of coordination with the Air Force and Navy should have been disturbing. Moreover, nobody asked how Langley was going to compensate for its lack of experience in engine development and testing (traditionally a Lewis task). It would not be as easy as it appeared.-1252

The proposed HRE engine was described as a "truly practical complete engine" that would provide "factual" performance data under real-world conditions. If researchers could have fulfilled all of the hopeful claims of the original proposal, this single engine project would have advanced the technology from the early exploratory research stage to an operational system. An elaborate subscale prototype engine was obviously required to fulfill such claims. Unfortunately, this was not what would be specified for the Phase I competition. Instead, the statement of work called for the "best possible research engine." While the Phase I engine would be required to deal with realistic internal flow conditions, it would not be required to consider the critically difficult high – temperature regeneratively cooled structure or to worry about external drag. In fact, the structure and external features were to be "refined only to the extent necessary for compatibility" with the internal flow performance requirements.12561

Rubert never openly acknowledged the downgrading of the engine concept from the advanced prototype referred to in the original proposal to an aerothermodynamic boilerplate. The rationale for the change was that project personnel soon realized that the limited funding they had requested could not possibly pay for a prototype engine; unfortunately, they continued to portray the engine as a prototype throughout the project. Ironically, the engine specified in the Phase I statement of work closely followed the 18-inch-diameter pod-type engine that had been suggested by Marquardt during the initial FRC study and was uniformly rejected by Langley and the other NASA centers.-12571

The decision to seek the highest possible internal performance and to impose no thrust-minus – drag requirement had several unfortunate consequences. In order to comply, the contractor that eventually won the Phase I competition used a higher-than-optimal degree of external compression, which caused extremely high external cowl drag. In the final design, designers thickened the cowl to house research instrumentation, aggravating the drag problem even further. In the end, the engine was capable of producing essentially zero net thrust (thrust minus drag). When outside researchers realized this, most of the already lukewarm support for the project vanished.12581

A Phase I request for proposals was issued to 35 potential bidders, calling for a nine-month, 27,500 man-hour (roughly 20 people) study to develop a concept and a preliminary design; determine performance, life, weight, and safety data; and provide a development plan, manufacturing plan, and costs for the Phase II effort. When the proposals arrived on 28 May 1964, only four companies had responded. A team of 50 engineers and researchers from Ames, Langley, Lewis, and the FRC convened to pick a winner. Significantly, there was only a single Air Force representative on the technical review panels. NASA awarded parallel study contracts to Garrett, General Electric, and Marquardt in October. The evaluators never thoroughly understood why Pratt & Whitney had chosen to submit a proposal, since nobody thought it was a "serious effort to compete."12591

Nine months later, the same small army of evaluators reconvened to look over the results of the three studies. The concepts were essentially unchanged by the nine months of effort, and the results seemed to favor Garrett. John Becker later said that there were "some flaws in the deliberations which led to Garrett’s selection," although he maintained they were honest mistakes and not deliberate attempts to mislead.12601

The Garrett engine was the smallest, simplest, and easiest to cool, and had the best structural approach of the three designs. The evaluators also believed that the engine had a very high research potential because of the quasi-two-dimensional nature of the flow in its shallow annular combustor. Researchers thought that this would simplify the analysis of the combustor data for use in any future two-dimensional combustor design. There was another powerful consideration in favor of Garrett: under the leadership of Anthony duPont, Garrett had exhibited an energy and zeal unmatched by the other companies. Drawing on $250,000 in company funds, it had built a full-scale HRE combustor model and later operated it successfully at the Navy Ordnance Aerophysics Laboratory in Daingerfield, Texas, under simulated Mach 6 conditions. This made it seem like the design was well along, and that developing an engine based on it would be a quick and inexpensive process.-261

The General Electric design, on the other hand, did not appear to offer a two-dimensional approach because its combustor annulus was too deep. The engine was also large, heavy, and hard to cool. The evaluation team also penalized General Electric because of its long development schedule and high cost, although in retrospect they were much more realistic than Garrett’s.261

The evaluators ranked the Marquardt engine developed by Ferri last because of its complex threedimensional flows and a general lack of substantiation of the claims made for it. The most serious question revolved around the thermal compression effect used to avoid having a variable – geometry inlet.[263]

As it turned out, there were three serious flaws in the evaluation. The supposedly simple twodimensional flow expounded by Garrett was illusory. The complex boundary layers, focused shock waves, and resulting separations and complex interactions made the actual flow virtually impossible to analyze, unique to this particular engine and undesirable from all standpoints. The generally better performance actually obtained with the General Electric combustor suggests that it should have received at least an equal rating. It is interesting to note that during his oral briefings to the evaluation board, Antonio Ferri had called attention to the problems of axisymmetrical design, including "focused shocks," "high losses," and "high cowl drag"-the same problems that were actually encountered by the Garrett engine. The evaluators unfortunately dismissed these comments as prejudiced.264

The second flaw in the evaluation was the belief that the study would reveal true time and cost estimates in a situation where the government told the contractors what the times and costs should be. The two contractors that fed back what the government wanted to hear were credited with "responsiveness," while the one (Marquardt) that provided more realistic (but unpopular) estimates was penalized. The last flaw was perhaps the most unfortunate. Garrett gave the impression that the already-developed model combustor could be easily made to work. However, its apparent success during early tests was the result of researchers not understanding the test conditions, and in reality the development of the combustor would prove to be the primary problem of the HRE. Garrett later blamed its misleading experience with this model for its gross underestimates of the true time and cost of the actual engine.261

There were also questions, even prior to Phase I, regarding whether Garrett had sufficient expertise to undertake the development of the HRE. The company had little experience with scramjet aerothermodynamics, and both management and technical personnel were inexperienced in this type of development effort. The fact that the company was proceeding with the development of the combustor model at its own expense was the primary consideration that overruled its inexperience.261

On 11 July 1966, NASA awarded Garrett the Phase II contract, but things quickly began to unravel during the negotiations for a final contract. Modifications and ground support equipment for X – 15A-2 would cost a staggering $8.7 million, vastly more than had been expected. Within six weeks, Garrett was proposing a $10 million increase in overall costs. Given the overall reductions

in funding caused by the conflict in Southeast Asia, NASA managers began to question the necessity for the program.[267]

At a meeting of the Aeronautics and Astronautics Coordinating Board on 5 July 1966, the Air Force announced it would stop funding the X-15 program in 1968 and that NASA would take sole responsibility for the majority of operational support (the military would continue to provide minor base support services). The withdrawal of Air Force support for the X-15 program was a serious setback because it meant that the NASA budget would need to find an additional $8 million per year, an enormous increase that was unlikely to occur. At the same time, there was another adverse development on the Air Force side: a gradual decrease in support for hypersonic technology in general, and scramjets in particular. Just before retiring from a long and notable career, General Bernard A. Schriever was unsuccessful in his attempt to obtain $50 million for an ambitious scramjet program.-1268

Finding additional NASA funding would not be easy. This raised significant questions about how to proceed to Phase II. Interestingly, the question of whether to proceed seems not to have been raised at all. In September 1966, Langley established a formal project office to oversee Phase II, with Rubert designated as the project manager, and by year’s end approximately a dozen people staffed the office.-1269

On the contractor side, the president of Garrett, Harry Wetzel, was getting "politely impatient" with the delay in getting started. In a letter to NASA administrator James E. Webb on 16 December 1966, Wetzel indicated that he might invoke "pre-project costs" under a provision of the contract if delays should continue. This appeared to have the desired effect because a plan was soon devised that split the former Phase II effort into Phases IIA and IIB. The first part would cover development and the manufacture of one pre-prototype, flight-weight engine. Phase IIB would subsequently produce six prototype engines for ground tests, qualification testing, and later flight tests as part of Phase III. NASA formally approved Phase IIA with a target cost of $15.6 million (including fee), and researchers estimated that Phase IIB would cost $13 million. However, nobody attempted to define a cost estimate for Phase III because it contained too many unknowns. In addition, project management did not address how to extend the X-15 program long enough to allow the engine to be developed, or how to pay for X-15 operations.-1279

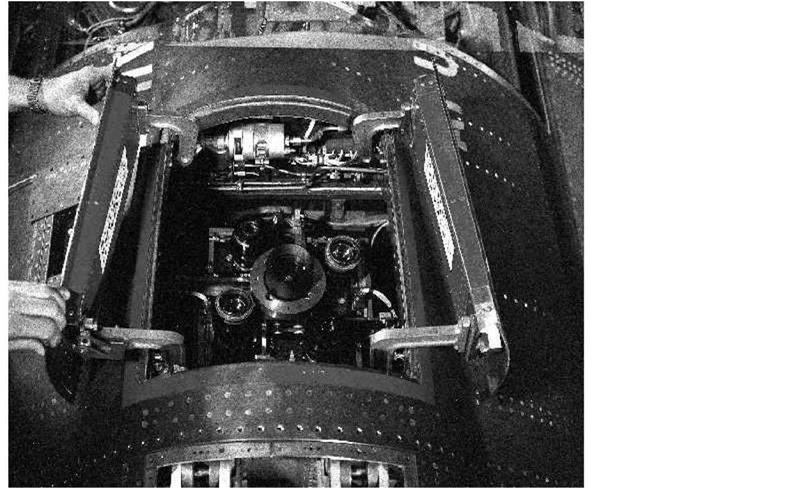

In the high desert, plans to fly a "dummy" ramjet shape on the modified X-15A-2 were taking shape. In order to gain basic aerodynamic data and investigate the effects of carrying a generic ramjet shape on X-15A-2, the FRC had several dummy ramjets constructed. None of these resembled the engine mockups that engineers had hung under the X-15 in the past. The FRC fabricated the dummy shapes, about 7 feet long and 2 feet in diameter, from a series of truncated cones. The program flew two different nose configurations: a 20-degree cone on flights 2-51-92 and 2-52-96, and a 40-degree cone on flight 2-53-97.-1271

To accommodate the dummy ramjet, NASA significantly modified the ventral stabilizer on X-15A – 2 by removing 2.8 feet from the front and adding a blunt, unswept leading edge. In addition, engineers removed approximately 3 inches of the lower surface for the first 3.3 feet of the ventral to allow the ramjet to be mounted in a semi-submerged location. Ten impact pressure probes were installed on the leading edge. Most of these protruded approximately 5 inches in front of the ventral, although the three closest to the ramjet were progressively shorter. The probes extended through the pylon standoff shock wave except near the ramjet, where they were made shorter to measure pylon-ramjet interference effects.-12721 smooth cylindrical surface of the lower fuselage of X-15A-2. This was the same camera window used for the Hycon/Mauer experiments (#27) and it protruded a maximum of 1.75 inches below the fuselage. This protrusion was located approximately 13 feet ahead of the leading edge of the pylon, or about 10.25 feet ahead of the tip of the 40-degree nose cone. For these tests, researchers installed a Millikan 16-mm movie camera to photograph the ramjet.-12731

Surface static-pressure orifices were located on the right side of the dummy ramjet and pylon. All orifices were normal to the surface and flush with the metal skin. When the ablative coating was used, an insert of higher-density ablative material at each orifice location maintained a sharp edge at the outer surface. The first flight with the 20-degree nose cone did not use any nose probes. The second flight with the 20-degree cone, and the only flight with the 40-degree cone used a rake with two 40-degree cone probes protruding from the extreme nose in an "L" shape. The top cone probe was on the ramjet centerline, and the lower cone was 8 inches below.12741

A wind-tunnel study conducted after the last X-15A-2 flight showed that shock waves generated by the wing leading edge, lower-fuselage camera window, and fuselage side fairing all impinged on the dummy ramjet and pylon. Researchers found that these were very sensitive to the angle of attack, with a 1% increase in free-stream angle of attack resulting in a 10% increase in impact pressure at Mach 6.5.12751

At the beginning of 1967, the program planners, who had originally expected the program to be completed by the end of 1969, did not expect to begin flight tests of an operable ramjet before 1971 at the earliest. The schedule had begun to slip even before the start of Phase I, when NASA extended the original four-year project 15 months just to accommodate the procurement cycle. However, there was little actual concern among those involved at the time since they believed the Air Force and NASA would extend the X-15 program as required. By 1967, that prospect was beginning to look less likely.12761

Faced with the long schedule extension, greatly increased costs, the loss of Air Force X-15 funding, waning interest in hypersonic technology in general, and the prospect for austere R&D funding in the years ahead, managers began to doubt they could complete the HRE program at all. In particular, they considered it unlikely that the necessary continuation of the X-15 program could be obtained using only NASA funding. In retrospect, it was obvious to most of those involved that the HRE should have died a natural death at this point. As is often the case, however, the project had developed a life of its own. Some believed that Phase IIA would develop useful scramjet technology regardless of what transpired in the future. Since there was still a minor chance that the X-15 program would continue with the development of the delta-wing cruise vehicle, Langley launched HRE Phase IIA on 3 February 1967 with the signing of the final contract with Garrett.12221

Any chance of flight-testing a real HRE vanished on 15 November 1967 when X-15-3 crashed, ending the proposed delta-wing program at the same time. Surprisingly, perhaps because researchers had long anticipated it, the actual demise of the X-15 portion of the program seems to have caused only minor distress in the HRE project office. Researchers suggested that the X-15 had served a very useful purpose by imposing "real" design requirements for the engine, but surmised they could realize some 90% of the program objectives even without actual flight tests.

By this time roughly half of the Phase IIA costs had been committed, and these would be lost if the HRE program was terminated. There would be other costs associated with terminating the project, possibly totaling the entire cost of Phase IIA; the decision was to let Phase IIA continue unchanged.-12781

Given the lack of a flight vehicle, NASA decided to reorient the HRE into a ground-based program. Ground testing moved from the Navy Daingerfield Facility to a newly completed test stand at the Lewis Plumbrook installation. In early 1968, Rubert told Garrett to stop work on the X-15 modification package and other items related to flight-testing, and the dummy ramjet eventually tested on X-15A-2 had little relation to the HRE developed by Garrett. As it turned out, stopping this work saved little money since the development of most flight subsystems continued in an effort to achieve a "realistic" engine. As John Becker later observed, "And thus was HRE adroitly decoupled from the X-15 which gave it birth and left to make its own way, apparently unchanged but actually now stripped of its glamour and its principle reason to exist."279

The HRE had survived the loss of the X-15 flight phase by only a few months when mounting cost and schedule overruns forced the abandonment of the original plan to develop and test a complete hydrogen-burning engine. Nevertheless, the program continued-with dubious results – until 22 April 1974, when NASA finally terminated it.2801

Although the original promoters of the HRE had oriented Phase I only toward an internal aerothermodynamic performance test model of a scramjet, the combination of the ambitious general claims made for the project and the X-15 flight requirements forced it in the direction of a much more costly subscale prototype with realistic structural and other subsystems. Much later John Becker estimated that the total cost of the entire HRE program, including 25 X-15 flights, would have exceeded $125 million, or about four times the original estimate. The total actually expended was $50.8 million, including $7.5 million charged to the rebuilding of X-15A-2 and the construction of the dummy ramjets at the FRC.2811

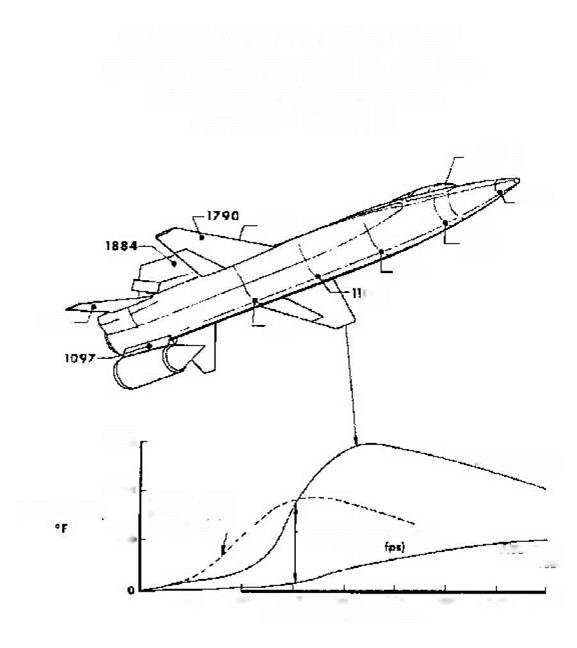

CALCULATED TEMPERATURES

CALCULATED TEMPERATURES