ІИіБ-31 Series

MiG 25MP / ЇВ-155МР / 83 MiG31 / 01

The MiG-31 was intended to counter a very specific threat: that of American B-52 bombers carrying long-range cruise missiles, each bomber representing several potential dangers all by itself (and conse-

The Ye-155MP numbered 831—product 83, no. 1—was neither a MiG-25 nor a MiG-31. It has the latter’s characteristic landing gear, but the airbrakes had to be moved and the wing strengthened

The MiG-31 takes shape in its definitive silhouette. The airbrakes were moved under the air intake ducts. The staggered twin wheels of the main gear were distinctive

|

The fairing for the 23 mm GSh-6-23 Gatling type cannon is visible beside the air intake duct under the wing leading edge root extension |

quently several targets) The future MiG-31 was to be capable of destroying multiple invaders at high or low altitudes in the forward and rear sectors and providing true look-down/shoot-down capability whatever the weather conditions, even if the invaders try to maneuver and use active countermeasures

At the start the prototype was referred to as the Ye-155MP On the aircraft’s nose the number “831" was painted to indicate that it was the first example of the izdehye 83 MiG’s internal product number The air – frame of this prototype was closely related to that of the Ye-155M. This was a sturdy, time-tested structure but the proportions of its metallic components were altered somewhat to 50 percent steel 16 percent titanium, 33 percent duralumin, and a negligible 1 percent composite materials (including the radome) The new aircraft did not need to be faster than the MiG-25P/PD, but it did need to offer a longer range This explains why the new aircraft—which was ten metric tons heavier than the MiG-25P/PD—was powered by two Solovyev D-30F6s rated at 9,310 daN (9,500 kg st) dry and 15,190 daN (15,500 kg st) with afterburner, the turbofan flight-tested on the Ye-155M,

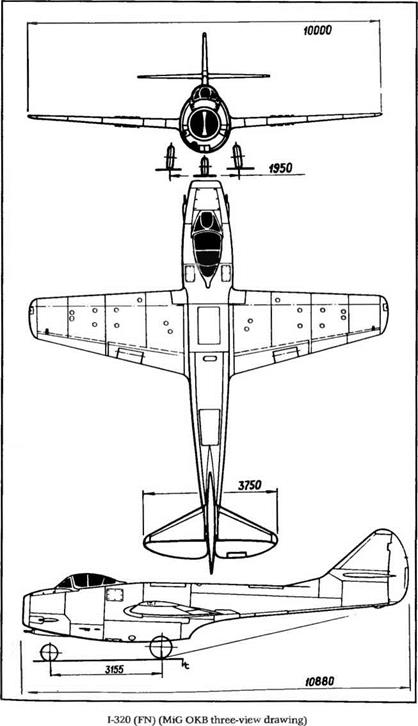

In what ways did the MiG-25MP izdeliye 83 differ from the MiG-25 izdehye 99?

1. It was a two-seater, a second crew member (the flight engineer) was needed to help manage its avionics

2. Both airbrakes were located under the air intake duct’s outboard corners (in front of the main gear doors) and were obliquely hinged

3. The main gear retracted forward, but the single wheels were replaced by staggered twin wheels arranged so that the rear wheel never followed the furrow of the front wheel; because of the aircraft’s weight it was important to distribute loads carefully, taking typical Russian weather conditions into account (winter snows and spring slushes)

4. Unlike the MiG-25, flaps and ailerons took up the whole trailing edge

The Ye-155MP was first piloted on 16 September 1975 by A. V Fedotov, but four long years of tests were needed before starting production in the Gorki factory in 1979. Those tests led to several significant modifications before the MiG-25MP reached the izdeliye 01 MiG-31 production stage:

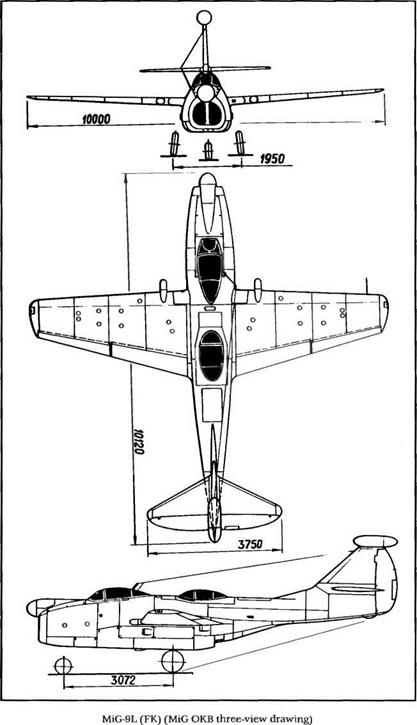

1 The whole of the wing’s leading edge was fitted with slats in four sections

2 Small, sharply swept leading edge root extensions were added

3. The aircraft was equipped with a semiretractable refueling probe on the port side of the nose cone

4. The wing box was strengthened by a third main spar so that the MiG-31 could fly at high supersonic speeds near the ground

5 Both airbrakes were moved squarely under the air intake ducts and hinged in the vertical plane

All of the MiG-31 ‘s combat capabilities relied on its interception system, which consisted of the S-800 Zaslon ("flanker") phased array look-down/shoot-down radar in the nose, the infrared search-and-track device in a semiretractable pod under the nose, and the tactical situation display. The radar had effective ranges of 200 km (125 miles) in the forward clutter-free sector and 120 km (75 miles) in look-down mode. In the rear sector those figures are reduced to 90 km (56 miles) and 70 km (43 miles), respectively. Ten targets could be tracked simultaneously, and up to four could be simultaneously engaged. The simultaneous lock-on and firing sectors covered plus-or-minus 70 degrees in azimuth and -60 to + 70 degrees in elevation.

As regards navigation, the position-finding accuracy was not influenced by the system’s time in service. For long distances the Marshrut ("itinerary”) system—similar to the West’s Omega—was accurate to between 2 and 5 km (1.25 and 3.10 miles); this margin narrowed to between 1.8 and 3.6 km (1.1 and 2.2 miles) for flight distances between 2,000 and 10,000 km (1,240 and 6,210 miles). For medium-range navigation the Tropik—similar to the West’s Loran — was accurate to between 250 and 1,300 m (820 and 4,265 feet); this margin narrowed to

|

411 |

between 130 and 1,300 m (425 and 4,265 feet) for flights under 2,000 km (1,240 miles)

The combat capability of the MiG-31 also relied upon information transmitted by a ground network of automatic guidance stations (ASU) operating in the following modes: remote guidance, semiautonomous guidance (coordinated support), isolated operation, and group operation (a flight of four interceptors exchanging information automatically). This latter mode requires some explanation. The leader is the only aircraft linked to the ground automatic guidance network designated AK-RLDN, but it can exchange information with the other three aircraft. Each aircraft is kept 200 km (124 miles) apart. The four are therefore lined up to cover a space 600 km (372 miles) wide; but because of their radar scanning angles (140 degrees) and the overlap of the scanned sectors, the overall zone swept by the four aircraft is 800-900 km (495-560 miles) wide.

The APD-518, a powerful digital data signaler, gives the leader and the wingmen a continuous flow of exchangeable information. All problems of guidance, target identification, and coordination between interceptor flights were then managed by the MiG-31’s avionics via the automatic data exchange between aircraft. The target allotment—just before attacking—is carried out by the flight leader according to the information provided by the tactical situation display.

The MiG-31’s armament was quite impressive:

1. Air-to-air missiles. Four long-distance (110-km [68-mile]) radar- guided R-33s under the fuselage, or four R-33s and two medium – range infrared-guided R-40Ts, or four R-33s and four short-range infrared-guided R-60TS, or two R-60s and two 2,500-1 (660-US gallon) drop tanks under four wing pylons. A new method of carrying the four bigger missiles—placing them in pairs beneath the fuselage, one behind the other—reduced drag considerably. Before firing, the missiles split off from the aircraft by means of special AKU ejecting pylons The missile’s engine is ignited and its homing device enabled once it is a safe distance out of the aircraft’s flight path.

2. Fixed armament. One Gatling-type 23-mm GSh-6-23 cannon with 260 rounds, fed by a linkless ammunition belt. The rate of fire is presently 6,000 plus-or-minus 500 rounds per minute (but should later be raised to 8,000 rounds per minute), and the initial speed is 700 meters per second (2,300 feet per second). This weapon is located on the right side of the fuselage behind the main landing gear.

The aircraft entered production in 1979 at the Gorki factory, and the first MiG-31-equipped regiments were operational by 1982 The

The simultaneous tracking and fire sectors covered plus-or minus 70 degrees in azimuth and -60 to +70 degrees in elevation.

Only four MiG-31s are needed to sweep a zone 800-900 km (495-560 miles) wide. The leader is the only aircraft linked to the ground stations, but all information can be exchanged between the four aircraft via the AFD-518 automatic data signaler.

MiG-31 project was managed by R. A Belyakov, assisted by bright team members such as G Ye. Lozino-Lozinskiy, V A Arkhipov, К К Vasilchenko, and A A Belosvyet

Specifications

Span, 13 464 m (44 ft 2 1 in), overall length, 22 688 m (74 ft 5 2 in), height, 6 15 m (20 ft 2 1 in), wing area, 61 6 m2 (663 sq ft), empty weight, 21,820 kg (48,105 lb); takeoff weight with 100% internal fuel, 41,000 kg (90 365 lb), internal fuel, 16 350 kg (36,035 lb); takeoff weight with 100% internal fuel and two 2.500-1 (660-US gal) drop tanks 46,200 kg (101,825 lb); wing loading, 665 6-750 kg/m2 (136 5-153 8 lb/sq ft); max operating limit load factor at supersonic speed 5

Performance

Max speed, 3,000 km/h at 17,500 m (1,863 kt at 57 400 ft); max speed at sea level, 1 500 km/h (810 kt); max cruising speed Mach 2.35; economical cruising speed Mach 0 85 service ceiling 20,600 m (67,570 ft); climb to 10 000 m (32 800 ft) in 7.9 mm landing speed, 280 km/h (151 kt); ferry range with 100% internal fuel and two 2,500-1 (660-US gal) drop tanks, 3,300 km (2 050 mi); max endurance with two 2,500-1 (660-US gal) drop tanks, 3 6 h; endurance with one in-flight refueling 6-7 h; radius of action at Mach 2 35, 100% internal fuel, and four R-33 missiles, 720 km (448 mi); at Mach 0.85, 100% internal fuel, and four R-33 missiles, 1,200 km (745 mi); at Mach 0 85, 100% internal fuel, four R-33 missiles, and two 2,500-1 (660-US gal) drop tanks 1,400 km (870 mi), at Mach 0 85, same conditions with one in-flight refueling 2 200 km (1,365 mi); takeoff roll at 46,200 kg (101,825 lb), 1,200 m (3,935 ft), landing roll, 800 m (2,625 ft)