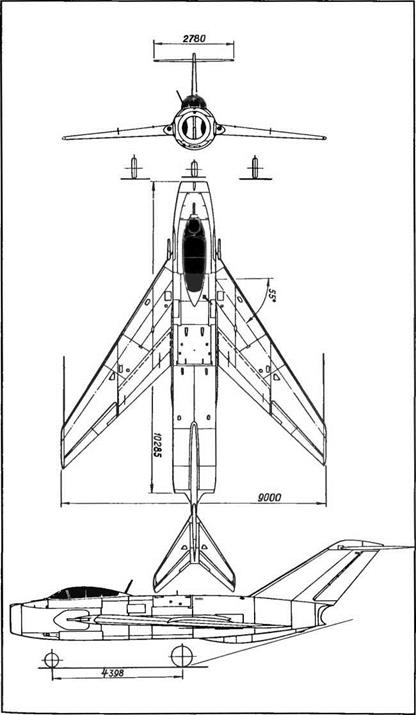

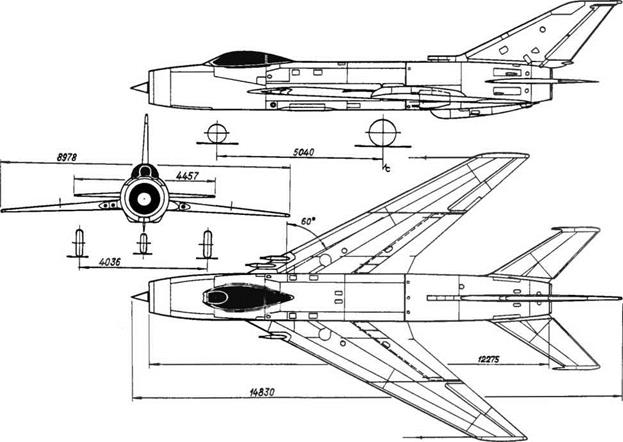

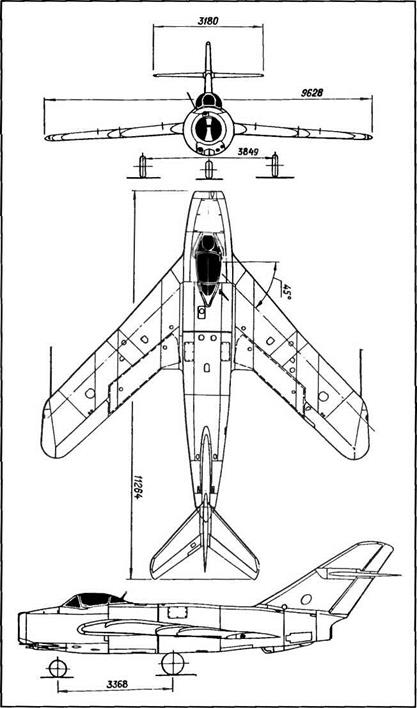

MiG-17 /1-330 / SI / MiG-15 bis 45° / SI 2/SI 02/SI 01

The next major challenge faced by MiG designers was to increase the maximum speed of a fighter solely by improving its aerodynamic factor—that is, without giving it a single additional pound of thrust. Both in silhouette and in structure, the SI-2 (prototype of the MiG-17) and its double the SI-3 looked very much like the MiG-15. (The SI-1 was set aside for static tests and never left the ground.) But there were many important differences:

—the wing sweepback C/4 (at quarter chord) was 45 degrees from the root to midspan (hence the aircraft’s designation) and 42 degrees beyond that, creating a sweepback on the leading edge of 49 degrees and 45 degrees, 30 minutes (this compound sweep came about not only because of trim considerations but also because the wing root rib had to be bolted to a section of the fuselage inherited from the MiG-15)

—the wing area was enlarged by 2 m2 (21.5 square feet)

—the anhedral was increased to 3 degrees with a 1-degree wing incidence

|

The Sl-2, the second 1-330 built, was the first prototype of the MiG-17 program to fly

|

|

|

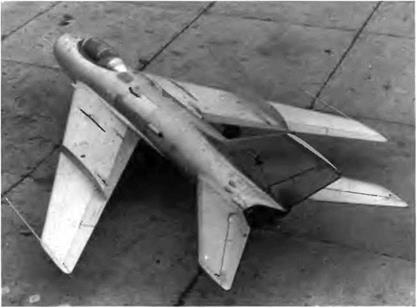

Note the leading-edge compound sweepback—45 and 42 degrees at quarter chord—of the SI-2, plus its six wing fences.

|

|

|

First-senes MiG-17 (MiG OKB three view drawing)

|

—the wing had six fences

—the wing profile was thinner, with a TsAGI S-12s at the root and a TsAGI SR-11 at the tip (wing aspect ratio, 4 08; taper ratio, 1.23: mean aerodynamic chord, 2.19 m [7 feet, 2.2 inches])

—the wing-to-fuselage junction was improved near the trailing edge —the fuselage was lengthened hy 900 mm (2 feet, 11.5 inches) in proportion to the sweepback increase —the area of the airbrakes was increased to 1.76 m2 (18.9 square feet)

The semimonocoque fuselage was built in two parts that joined at the main wing-fuselage splice fittings to facilitate engine removal and replacement. The cockpit was pressurized and air-conditioned. The hood was made of a 64-mm-thick bulletproof glass windshield and a sliding canopy. In the lower part of the fuselage beneath the cockpit, an inspection panel allowed for easy access to the cannon tray The cockpit was equipped with a first-generation ejection seat controlled by handles on both armrests.

The monospar wing, reinforced with stiffeners and a stressed skin structure, had a 12-percent thickness ratio. The ailerons each had a span of 1 512 m (4 feet, 115 inches), an area of 0.8 m2 (8.6 square feet), and a maximum deflection angle of plus or minus 18 degrees, and they were balanced internally. The aileron on the right side was fitted with a tab measuring 0 034 m2 (0 37 square feet), and the aileron control was boosted by a hydraulic servo-control The Fowler-type flaps (span, 4 m [13 feet, 1.5 inches]; area, 2.86 m2 [30.8 square feet]) had two settings. 20 degrees for takeoff and 60 degrees for landing. The fin had a sweep angle of 55 degrees, 41 minutes at the leading edge and a total area of 4.26 m2 (45.85 square feet), including 0.947 m2 (10.2 square feet) for the rudder The horizontal tail—an ASA-M airfoil—had a sweep angle of 45 degrees at the leading edge and a total area of 3.1 m2 (33.37 square feet), including 0.884 m2 (9.5 square feet) for the elevator.

Two bladder tanks with capacities of 1,250 1 (330 US gallons) and 150 1 (40 US gallons) were located behind the cockpit. They could be placed in the fuselage via the cannon access port, and because of their location their contents had no effect on the aircraft’s trimming. Two store stations beneath the wing could receive either two drop tanks or two 100-kg (220-pound) or 250-kg (550-pound) bombs. Other equipment included the RSIU-3 Klen ("maple") VHF and the SRO-1 Bariy-M IFF transponder as well as the OSP-48 ILS, which included the ARK-5 Amur automatic direction finder, the MRP-48 Khrizantema (“chrysanthemum”) marker receiver, and the RV-2 Kristall low-altitude radioaltimeter. Its armament was identical to that of the MiG-15: one N-37D with forty rounds and two NR-23s with 80 rpg.

|

Armament on the SI-2 is identical to that on the MiG-15 and MiG-15 bis The landing light in the air intake partition was later moved.

|

|

|

The SI-02: third prototype built, second to fly, and first production-line MiG-17.

|

|

|

The SI-02 with airbrakes deployed and flaps lowered at the landing setting

|

The SI-2 was flight-tested by I. T. Ivashchenko An in-depth test sequence was planned, including even the most difficult aerobatic maneuvers. From the start Ivashchenko noted that the SI-2 was 40 km/h (22 kt) faster than the MiG-15 bis, and on 1 February 1950 he reached 1,114 km/h (602 kt) in level flight at 2,200 m (7,215 ft). But 20 March proved to be a fateful day for the aircraft and its pilot. After completing the day’s exercises at 11,000 m (36,080 ft), Ivashchenko started to descend normally when suddenly the aircraft dived and crashed.

After the tragic death of the pilot, it took more than a year to establish the causes of this accident, remedy them, and build a new prototype, the SI-02. (The SI-01, whose assembly was delayed, rolled out of the factory after the SI-02 and was thus the fourth prototype.) To test this machine Mikoyan called on a military test pilot, G. A. Sedov. The SI-02 passed its factoiy tests and state acceptance trials in short order. In decree no. 851 of 1 September 1951 the GK Nil WS and the ministry of aircraft production ordered mass production of the aircraft in no fewer than six factories (recall that the MiG-15 was built in eight factories).

The MiG-17 was able to carry out the most complicated aerobatic maneuvers, but it was necessary to impart a greater deflection to the control surfaces than was the case with the MiG-15 bis. Moreover, its

|

The SI-01—fourth prototype built, third to fly—was rolled out after the SI-02, delayed by production problems. It carried two 400-1 (106-US gallon) slipper tanks.

|

acceleration after takeoff had deteriorated somewhat. With the help of its airbrakes the MiG-17 was able to roll at any speed or altitude up to

14,0 m (45,920 feet). The area of the airbrakes was increased slightly on the assembly line starting in September 1952.

At high altitudes the MiG-17 was a very stable aircraft. It was even possible to roll in at its operational ceiling without losing much altitude. However, at 270-280 km/h (146-151 kt) its gliding descent speed was significantly faster than that of the MiG-15 bis. Several modifications were made on the assembly line to improve the aircraft’s structure and safety. For instance, the ejection seat was fitted with a tight strap slinged to the pilot’s bucket. With that safety device the pilot was much better secured. And like the MiG-15, the left armrest of the pilot’s seat was equipped with a backup activator for the ejection seat in case the pilot’s right hand was wounded in flight. As early as the end of 1953, all MiG-17s were equipped with a more modern curtain-type ejection seat that could be used safely at various speeds. This seat— developed by MiG—protected the pilot’s face from the relative wind, was equipped with stabilizing panels meant to prevent a disorderly free-fall, and secured the pilot’s legs. The OKB also developed for the MiG-17 a one-piece canopy (without a rear arch) that improved the pilot’s field of vision in the rear to between 24 and 27 degrees on both

|

Performance Comparison of the MiG-17 and the My store IV

|

Aircraft

|

MiG-17

|

Mysore IV

|

|

Takeoff weight

|

5,200 kg (11,460 lb)

|

7,400 kg (16,310 lb)

|

|

Engine thrust

|

2,645 daN (2,700 kg st)

|

3,430 daN (3,500 kg st)

|

|

Maximum speed

|

1,114 km/h (602 kt)

|

1,090 km/h (589 kt)

|

|

Flight endurance

|

1 h 50 min

|

1 h 10 min

|

|

Armament

|

1 x 37 mm and 2 x 23 mm

|

2 x 30 mm

|

Source: MiG OKB

|

sides. Nevertheless, the rearward view—so important in a fighter—was not totally panoramic. That is why periscopes, the only piece of equipment that offered a 360-degree view, soon made their appearance.

The VK-1 turbojet generated the equivalent of 12,000 shaft horsepower (shp), ten times the power of the AM-35A piston engine of the first MiG aircraft. Before long the MiG-17 was equipped with the VK – 1A, which also delivered 2,645 daN (2,700 kg st) but had a much longer service life. The MiG-17 as well as the last series of the MiG-15 bis was fitted with a new starting system that could use either a ground power unit or an airborne storage battery, making the aircraft self-contained. However, the start cycle was longer in the self-contained mode (forty – four seconds versus thirty seconds). The fuel system was greatly improved by inserting a pressure relief valve in the drop tanks’ pressurization pipes to ensure a regular flow of fuel at all operational speeds. Finally, the landing light was moved from the engine air intake to a place under the wing.

The SI-02 tests revealed a few structural shortcomings. For example, during one flight strong vibrations were felt in the elevator. By yanking and throttling back immediately Sedov thought he could stop the vibrations, but the elevator had already partly disintegrated. By trimming the aircraft on its glide path solely with the throttle, Sedov managed to return to the airfield and land. The cause of the vibrations was identified, and the aircraft was modified accordingly. Ever since, pilots have had nothing but praise for the performance of the MiG-17.

In tests two LII pilots, S. A. Anokhin and P. I. Kazmin, achieved Mach 1.14, a speed that was never used operationally.

At different times, nearly forty countries on three continents chose the MiG-17 for their air forces: Albania, Algeria, Afghanistan, Angola, Bulgaria, Cambodia, China, the Congo, Cuba, Czechoslovakia, East Germany, Egypt, Ethiopia, Finland, Guinea, Hungary, India, Indonesia, Iraq, Madagascar, Mali, Mongolia, Morocco, Mozambique, Nigeria, North Korea, Pakistan, Poland, Rumania, Sri Lanka, Somalia, the Sudan, Syria, Uganda, Vietnam, Yemen, and Yugoslavia. The aircraft has proven itself in combat, first in Egypt in the fall of 1956 against French Mystere IVs as well as British Vampires and Meteors. It is interesting to compare the characteristics of the MiG-17 with those of a contemporary fighter, the Dassault Mystere IV (see table). In the early 1960s MiG-17s twice engaged American F-105 Thunderchiefs and F-4 Phantoms over North Vietnam.

From this basic airframe the MiG OKB developed a full range of tactical fighters for specific missions, endowing this aircraft with a great versatility. The MiG-17 has also been used as a testbed for a number of systems intended for the next generation of fighters.

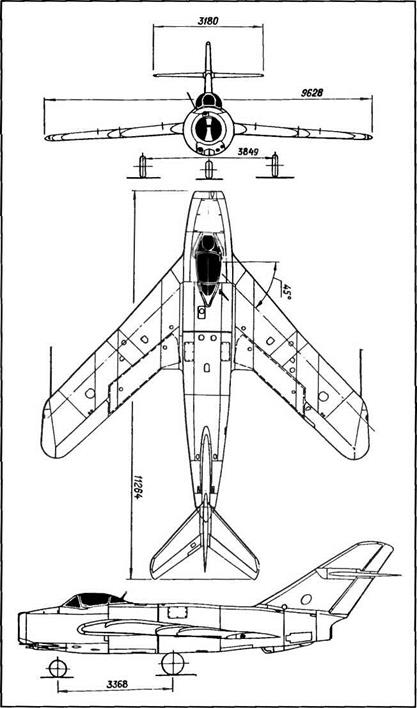

Specifications

Span, 9.628 m (31 ft 7 in); overall length, 11.264 m (36 ft 11.5 in); fuselage length, 9.206 m (30 ft 2,4 in); height with depressed shock absorbers, 3.8 m (12 ft 5.6 in); wheel track, 3.849 m (12 ft 7.5 in); wheel base, 3.368 m (11 ft 0.6 in); wing area, 22.64 m2 (243.7 sq ft); empty weight, 3,798 kg (8,371 lb); takeoff weight, 5,200 kg (11,460 lb); max takeoff weight, 5,929 kg (13,068 lb); fuel + oil, 1,173 kg (2,585 lb); wing loading, 230-262.3 kg/m2 (47.2-53.8 Ib/sq ft); max operating limit load factor, 8.

Performance

Max speed, 1,114 km/h at 2,000 m (602 kt at 6,560 ft); max speed at sea level 1,060 km/h (572 kt); Mach limit (fluttering conditions), 1.03; climb to 5,000 m (16,400 ft) in 2 min; to 10 000 m (32,800 ft) in 5.1 min; service ceiling, 15,600 m (51,170 ft); landing speed, 170-190 km/h (92-103 kt); range, 1,295 km at 12,000 m (805 mi at 39,360 ft); 1,185 km at 10,000 m (735 mi at 32,800 ft); range with two 400-1 (106-US gal) drop tanks, 2,150 km at 12,000 m (1,335 mi at 39,360 ft); 1,907 km at

10,0 m (1,184 mi at 32,800 ft); takeoff roll, 535 m (1,755 ft); landing roll, 825 m (2,700 ft).